The VeloVac Full Line in pocket size thanks to 3D and AR

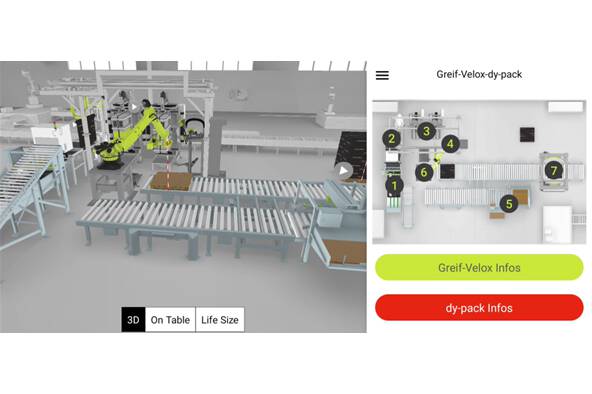

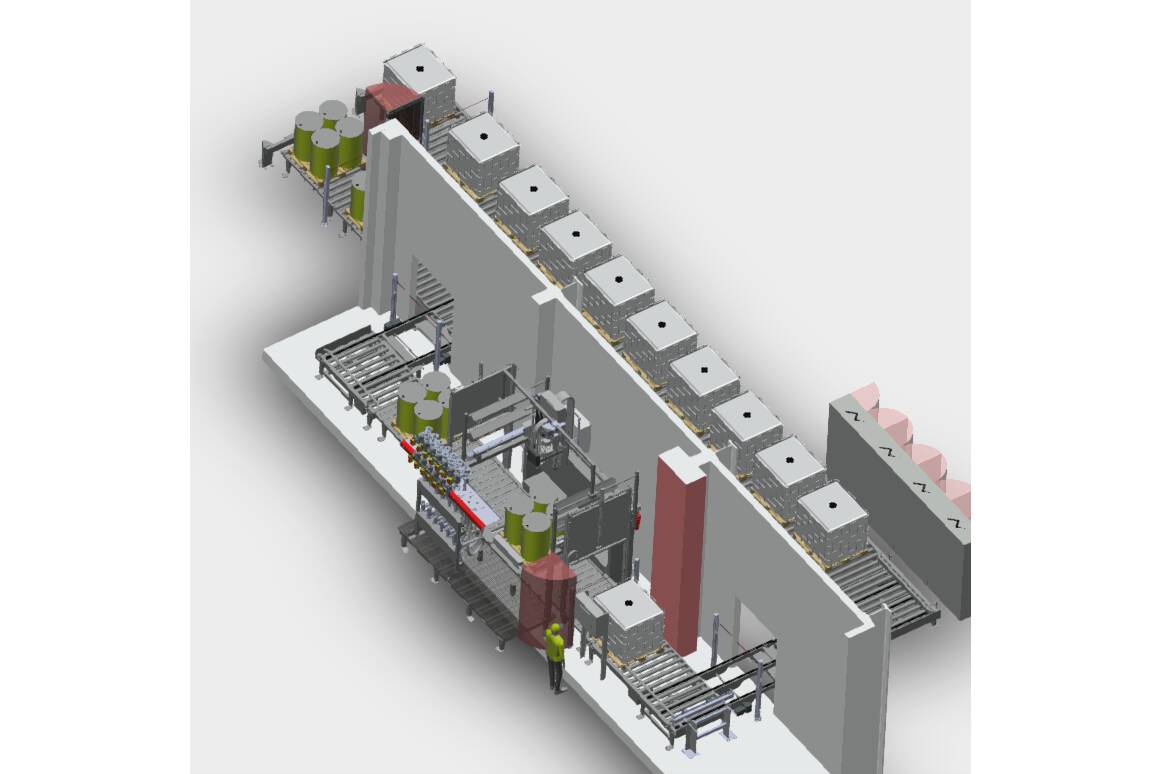

With the Vuframe app, you can explore the entire VeloVac bagging line including vacuum packer in impressive 3D and 360-degree perspective directly on your smartphone or tablet. Supported by augmented reality (AR), this is even possible in life-size. Thanks to the partnership between Greif-Velox, the leading paper sack manufacturer dy-pack and the innovative 3D platform Vuframe, the technology behind our VeloVac Full-Line vacuum packer system becomes accessible in a revolutionary digital format. By simply downloading the Vuframe app, interested parties can discover the bagging line from anywhere in a photorealistic 3D representation - generated in detail as a digital twin directly from the original design data.

The Vuframe app offers three immersive experiences:

* 3D view: interact with the installation by rotating, zooming and launching specific actions directly on your touchscreen.

* on-table AR: project the entire system onto your table in augmented reality and view it from all angles.

* life-size AR: Explore the VeloVac Full-Line in its true size. By scanning your surroundings in advance, the system can be projected life-size into your room.

Vivid, impressive and resource-saving

”The Vuframe app