Screw feeders - Screw Feeders are constant displacement devices that employ a variable speed drive to provide volumetric control of powder flow.

Screw conveyors - Screw conveyors accept a controlled feed from upstream equipment such as a screw feeder or a rotary valve.

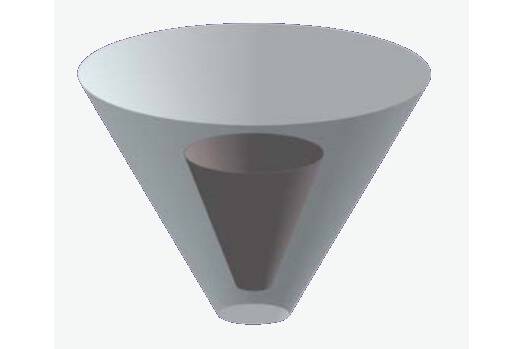

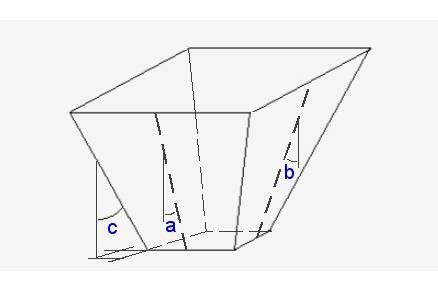

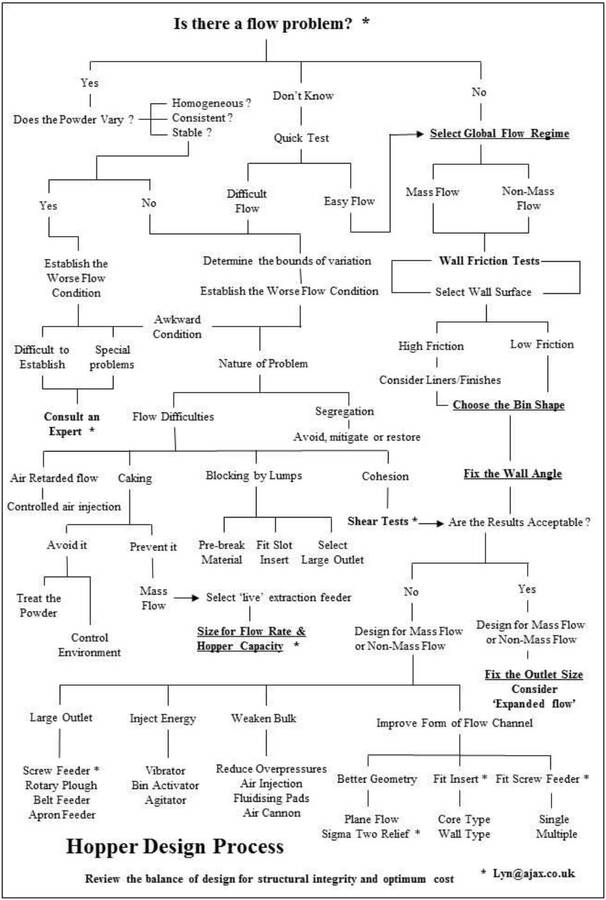

Hoppers - Hopper Design, Hopper Inserts. Hopper and Feeder Interface, Powder Testing for Flow

Continuous mixers - AJAX mixers produce a high quality mix at the ’scale of scrutiny’ because of the efficient multiple and progressive actions of paddles or ribbons.

Lump breakers - Multiple mechanisms are used by the Ajax lump breaker to reduce the lump size.

Rigid IBC’s - The LynFlowTM bin system matured from many years of expertise by Ajax in powder technolog

Heat exchangers - The AJAX range of screw based continuous heat transfer equipment includes machines to heat or cool materials (whilst mixing or conditioning)

Screw flights - AJAX Equipment produce screw augers and flights only for new applications as well as damaged or worn out equipment.

Screw elevators - Ajax screw elevators are offered for a wide range of throughputs, product characteristics and site layout needs

Sack Tip Stations - AJAX Sack Tip stations feature an enclosed chamber in which sacks may be emptied remotely avoiding generation of dust clouds and wastage of product.

Powder Testing for Flow - powder properties, bulk flow characteristics: bulk density, wall friction, shear strength