Elevator misalignment detector ATEX approved

Rub-Block with a PT100 sensor The Rub-Block RB200DN with a PT100 temperature sensor is designed to report the misalignment of a

conveyor or elevator belt. The advantage of the Rub-Block is the fact that it will send a continuous

output signal to the PLC.

The Rub-Block emits a permanent life standby signal. If such a signal is absent, this must be investigated and if required the PT100 sensor must be replaced. As long as the Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it. Off-tracking belts running into the side of conveyor equipment will cause friction, which may cause damage to the belt, and may generate heat, fire, or a dust explosion.

The Rub-Block is very easy to install, it will be fitted on both sides of a conveyor or elevator belt.

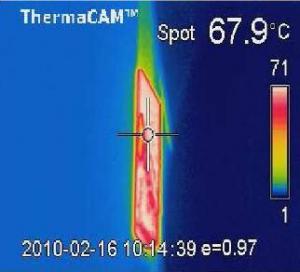

Once the belt off-tracks and runs onto the brass plate of the Rub-Block, it will create friction and the

temperature of the Rub-Block brass plate increases.