More efficiency and profit by accurate weighing

Preventing waste by more accurate weighing and dosing. A summary of where weighing can assist your process and save you money. Given the constantly rising prices of raw materials, the investment in accurate weighing and precise filling is worthwhile more than ever. In this article, we give some examples of how to achieve optimum efficiency with proven technology.

Intake with ship unloader

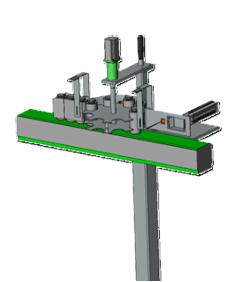

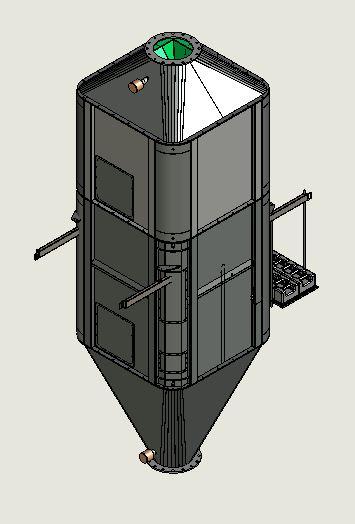

When discharging vessels or transporting via conveyor belts, a throughput weigher can be used to weigh the continuous bulk flow in batches. A built-in bunker weigher allows the individual weights to be totalised and the product flow to be recorded accurately. It becomes even more efficient if this can be done via a mobile installation.

Incoming and outgoing control with weighbridge

To keep a good eye on the global product flow of your company, all goods that enter or leave your plant should be weighed. The weighbridge can be linked to access control systems such as number plate cameras, barriers, badge systems, etc., making it impossible to enter or leave the site without being weighed. Logging in