Glatt-lab unit with increased and improved flexibility

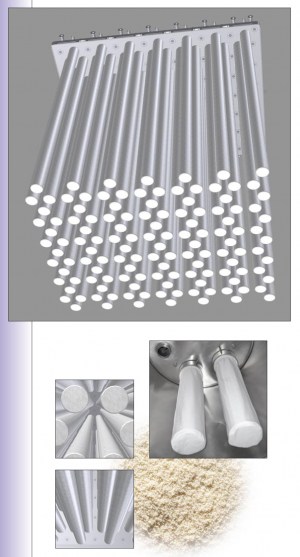

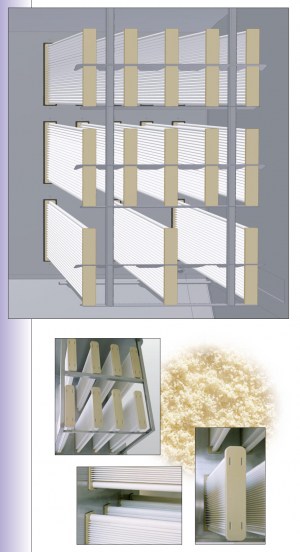

ProCell LabSystem for testing fluid bed and spouted bed processes „ProCell LabSystem“ is not only the new name of the largest mobile Glatt lab unit –but, all fluid bed and spouted bed processes can be tested in batch and continuous mode with only one equipment. The continuous operating mode is especially preferred for the liquid-only , spray granulation process. In batch mode this process can be tested only within narrow limitations.

The “ProCell LabSystem” has evolved from the lab unit ProCell 5, which has been sold and rented to numerous customers. This customer experience and satisfaction was driven by the excellent operating reliability and process flexibility of the equipment. The “new” lab unit will now offer four different process systems.. Customers can select one, two, three or all four process options, based on the needs of the desired product or project, as necessary.

Using the “ProCell-system”, spouted bed processes can be tested. The spouted bed technology is extending the possibilities to process