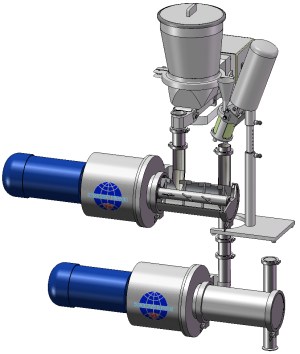

GEA Niro Soavi NS3006 2 stage high pressure homogenizer

for sale at Surplus Select Homogenizer, GEA Niro Saovi, Ariete NS3006L, 2 stages, sanitary execution, max. viscosity 10,000 cP, max. working pressure 1,000 bar, max. flow rate 120 L/h, max. product temp. 90 degree Celsius, suitable for CIP and SIP, Monoblock VHP compression head, ceramic plungers, 32,6 operating hours, technical data in English available, manual in Dutch, has been used in a pilot plant in the food industry