Hydronix releases new water controller for concrete production

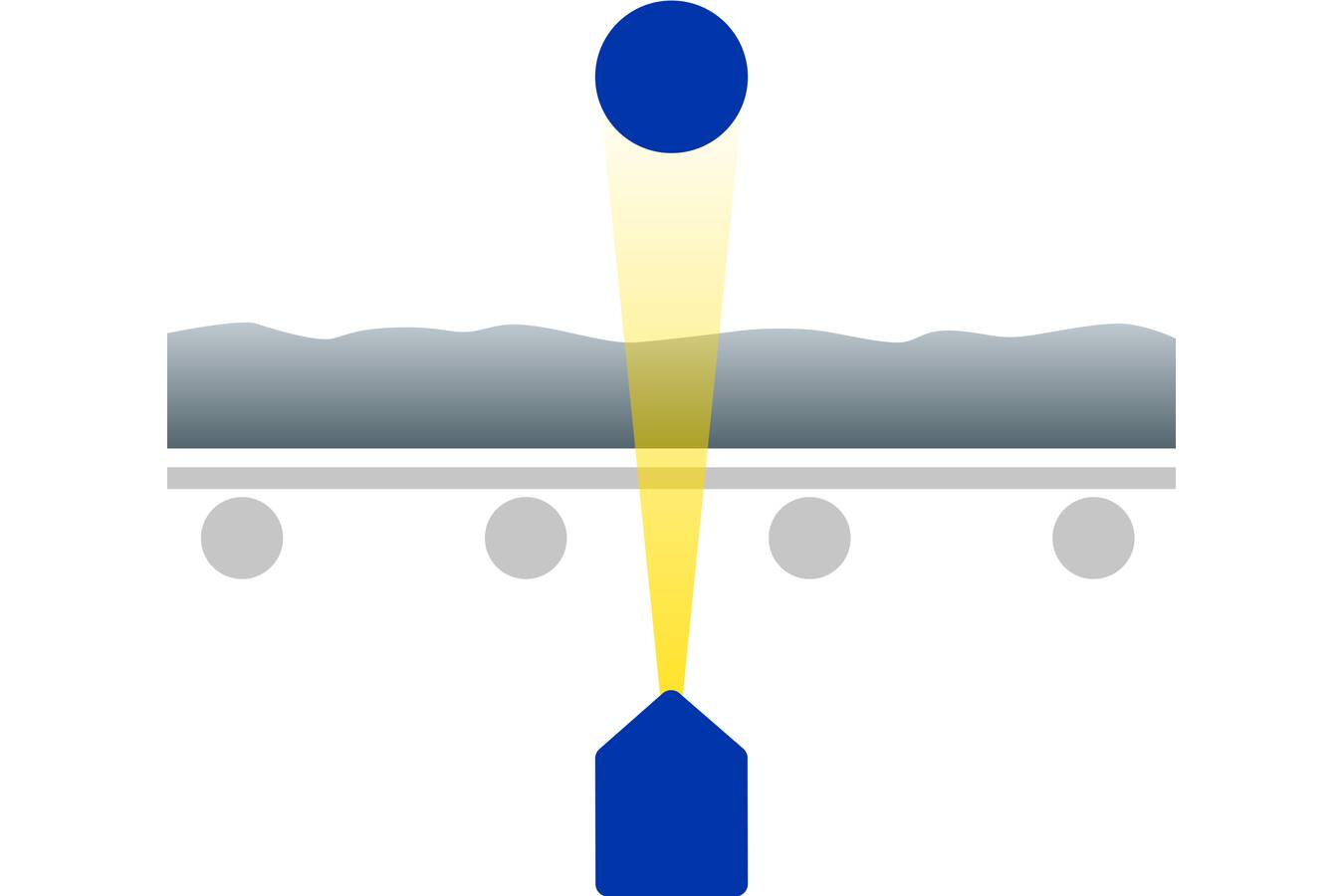

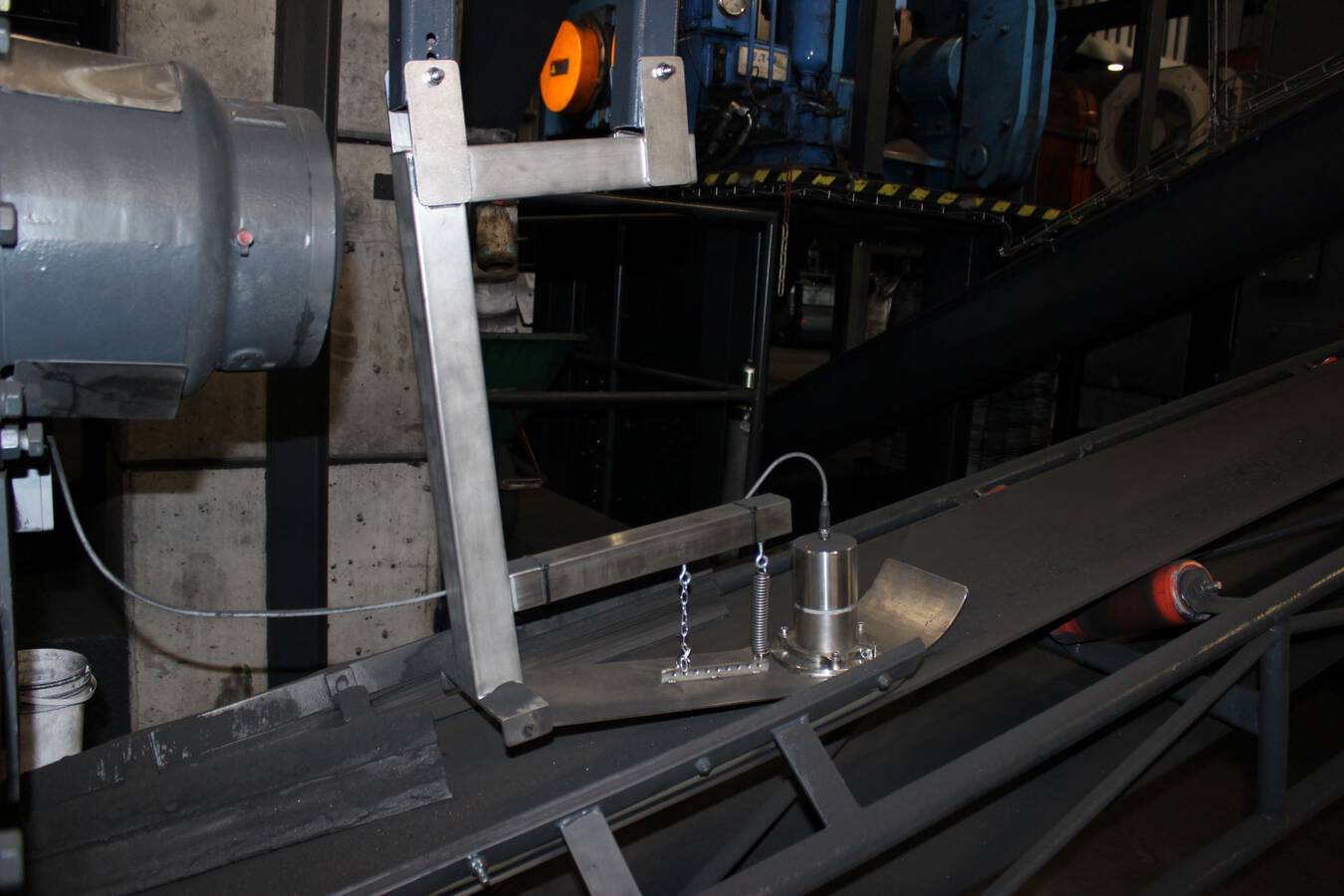

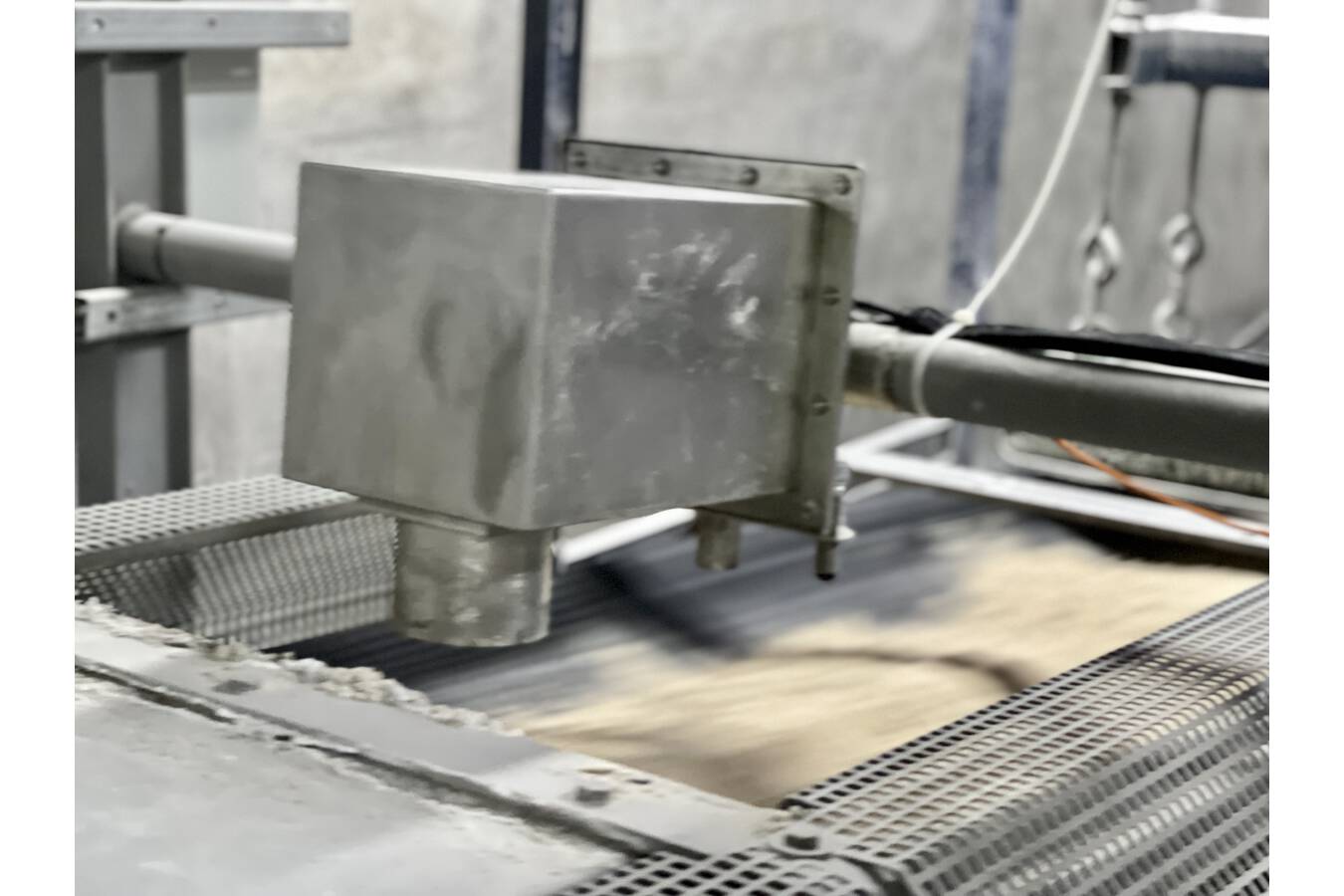

Hydronix is releasing the latest version of the Hydro-Control (model HC07)water controller compatible with the Hydro-Mix and the Hydro-Probe Orbiter. Hydronix, the leader in digital microwave moisture measurement, is releasing the latest version of the Hydro-Control (model HC07), a 10.1” touchscreen water controller compatible with the Hydro-Mix and the Hydro-Probe Orbiter.

The Hydro-Control is a stand-alone unit designed to accurately add water into a mixer, including weighed, metered, and timed methods. Different operating modes can be chosen for each recipe, enabling the most suitable option to be selected. Over 99,000 recipes can be stored.

Hydronix Hydro-Control (HC07)

The latest release of the Hydro-Control enables connection to a control system via ethernet, WEB API or an RS232 serial link. It is now possible to secure remote access through a web browser.

Neal Cass, Sales Manager at Hydronix, explains that “at Hydronix, we understand our customers’ challenges and data connectivity is becoming vital. We have updated the Hydro-Control with connectivity in mind, and the updated unit provides a flexible