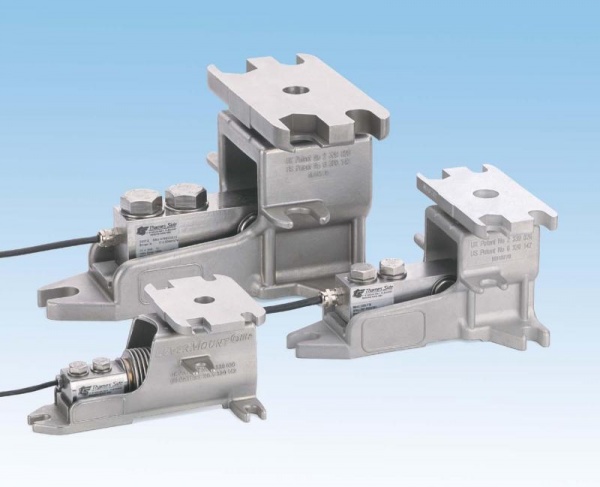

An advanced mounting assembly for load cells, the Levermount

Building weighing systems made easier. For contemporary industrial weighing, strain gage load cells are the standard. Characteristics such as a high accuracy, reliability, compact sizes and universal application contribute to their popularity. In practice, the value of correct and precise mounting of load cells is hugely under estimated. A loading assembly will assist in the tricky task of setting up load cells in the most effective manner. First of all, a good loading assembly guarantees proper force introduction, protecting against unwanted forces while providing a lift off protection at the same time. Secondly, modern loading assemblies allow for installation of the load cell during construction time, for example while welding, drilling and grinding, is done. In this way, they prevent the load cell from overload or the load cell cable accidentally being cut during mounting. As soon as the construction is finished the load cell can be installed and secured, rendering the system weighing. The Levermount