We offer process engineering solutions for all kinds of bulk solids – since 1873. Our product portfolio includes screening machines, big bag filling and emptying systems, mixing technology as well as laboratory equipment. In addition to our single machines we also manufacture tailor-made solutions and complex bulk handling systems which we develop in close collaboration with our customers: from engineering through to commissioning.

Products, services

Sieving machines - vibrating sieve, long stroke sieve, centrifugal sieving machine, particle measuring device

Big Bag emptying - big bag unloading station, big bag emptying station, big bag emptying plant

Big Bag filling - big bag filling station, big bag filling plant

Mixers, mixing - free-fall mixer, thrust mixer, turbulent mixer, drum hoop mixer

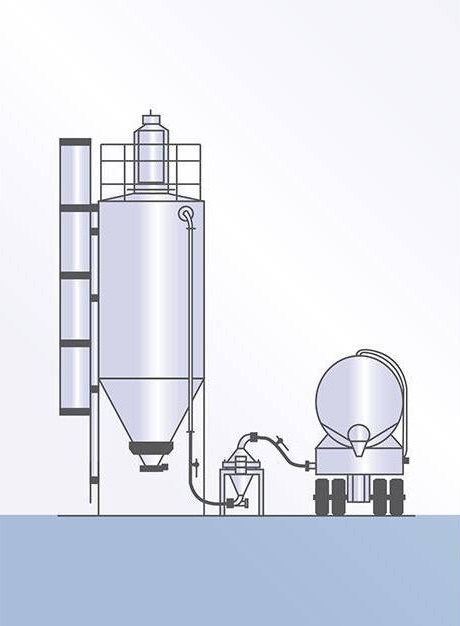

Plant technology - in the fields of screening, mixing, conveying, dosing and weighing

-

Categories

Handling - Handling of big bags - Discharge systems for big bags -

Big bag discharge systems for difficult flowing productsHandling - Handling of big bags - Discharge systems for big bags -

Big bag discharge systems using vibrationMixing, blending - Mixers -

Conical mixersMixing, blending - Mixers -

Container mixersMixing, blending - Mixers -

Drum mixersHandling - Handling of drums, barrels -

Emptying drums, barrelsHandling - Handling of big bags - Discharge systems for big bags -

Gravity based big bag discharge systemsHandling - Handling of big bags - Filling systems for big bags -

Mechanic filling of big bagsHandling - Handling of bulk containers, IBC`s - Filling systems for bulk containers -

Mechanic filling of bulk containers, IBC`sHandling - Handling of big bags - Filling systems for big bags -

Pneumatic filling of big bagsHandling - Handling of bulk containers, IBC`s - Filling systems for bulk containers -

Pneumatic filling of bulk containersSeparation, sieving, filtering - Sieving, sieves -

Rotary sievesSeparation, sieving, filtering - Sieving, sieves -

Shake sievesSeparation, sieving, filtering - Sieving, sieves -

Vibratory sieves