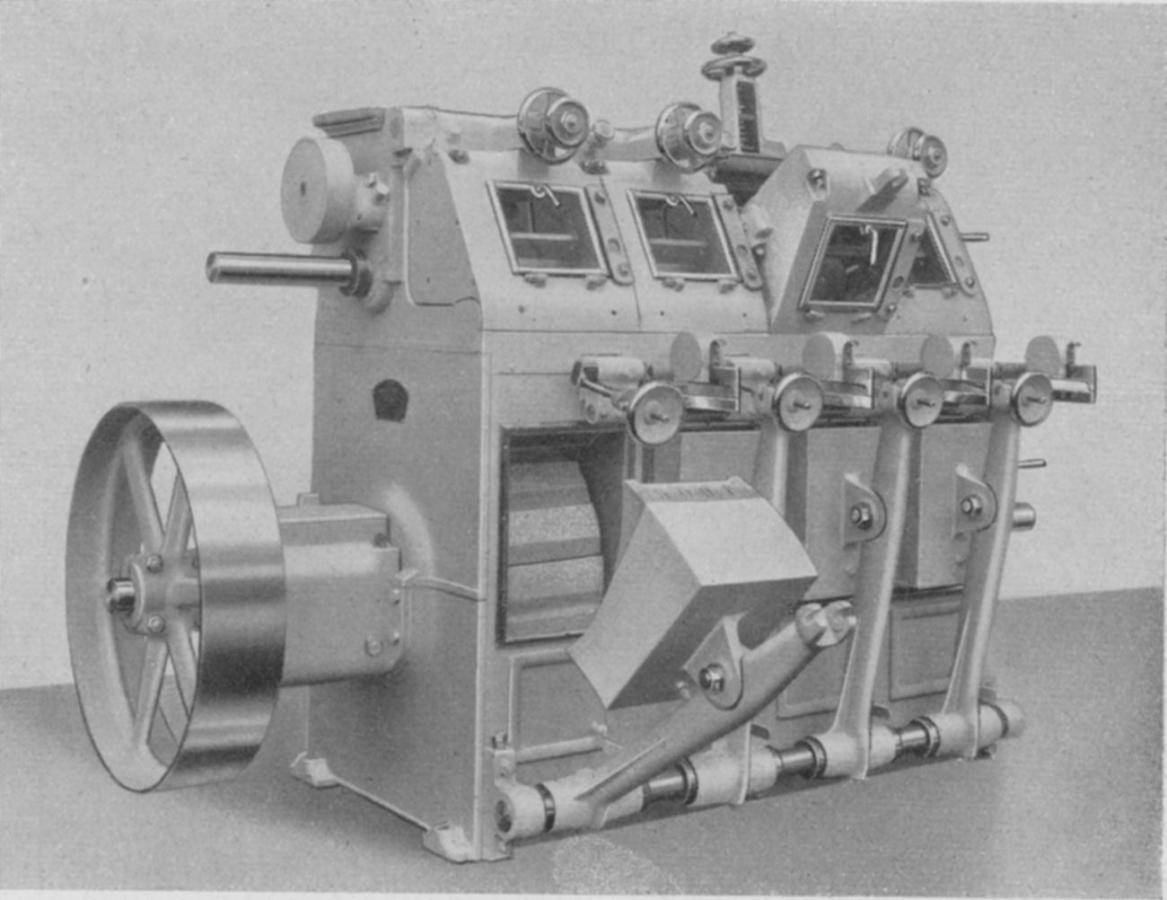

Gericke - Specialist for bulk material processing - a Swiss company since 1894.

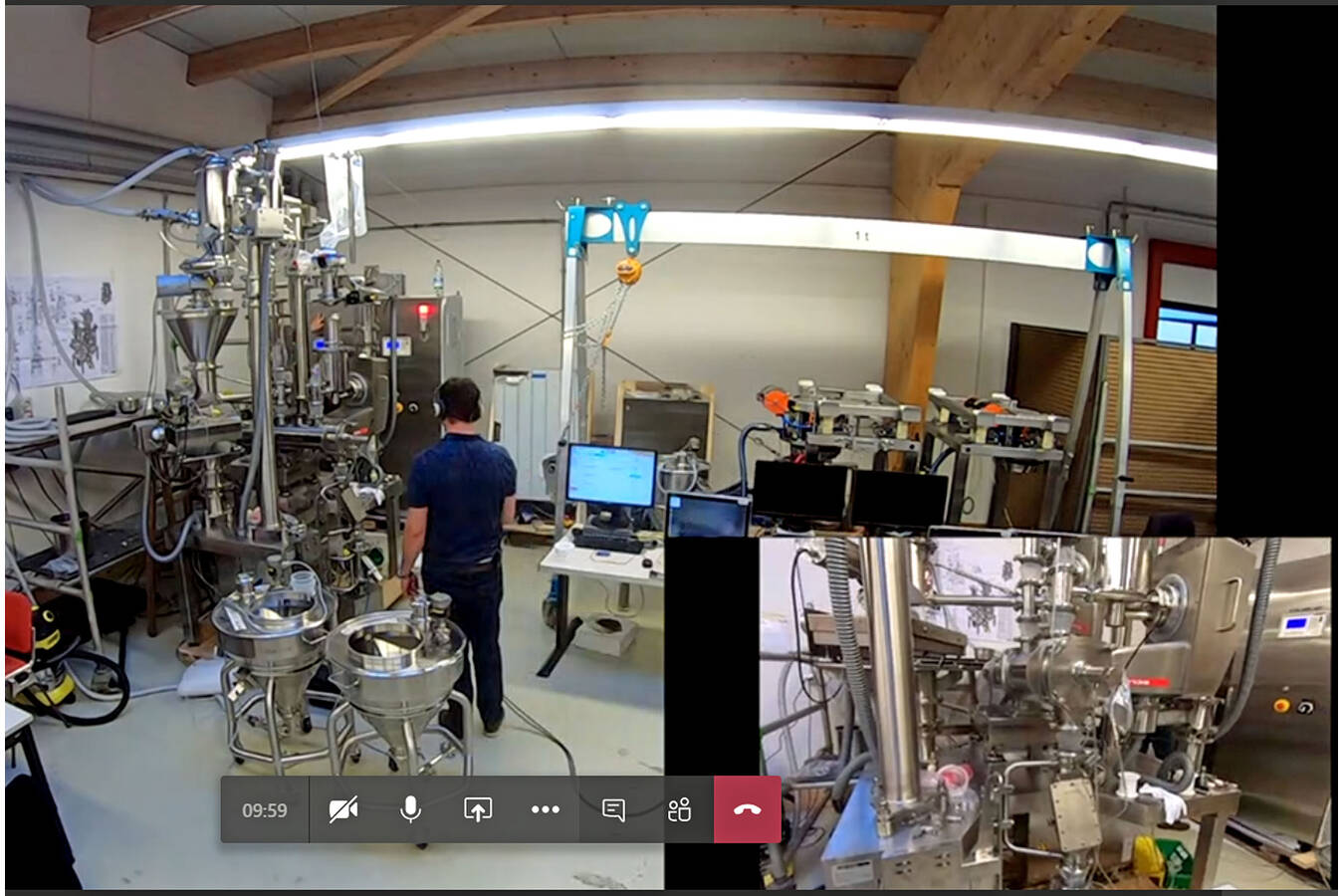

We are a well-known company on the world market in the field of bulk solids technology with headquarters in Regensdorf and subsidiaries in Germany, Great Britain, the Netherlands, France, USA, Brazil, Singapore, Indonesia, Malaysia, Thailand and China.

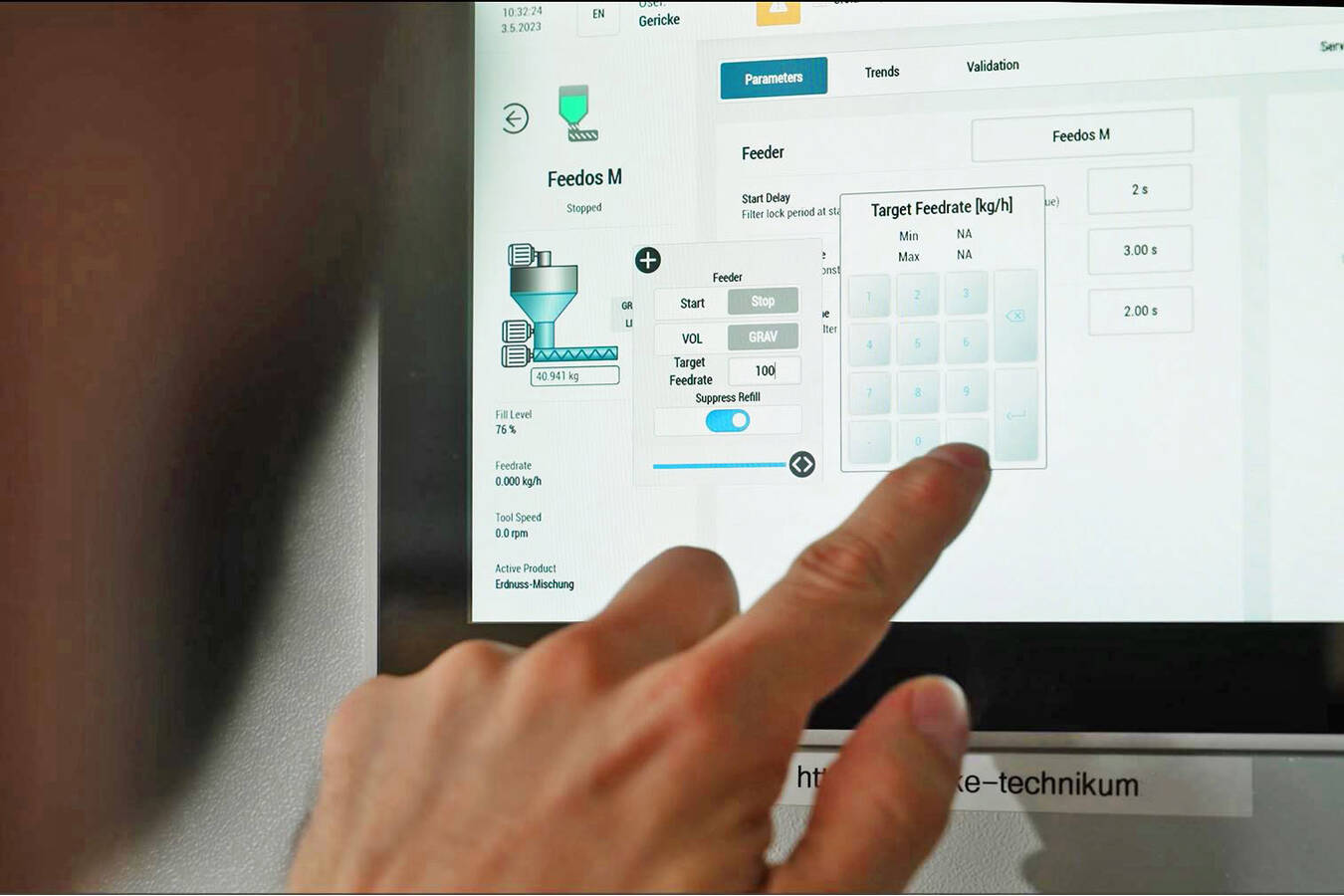

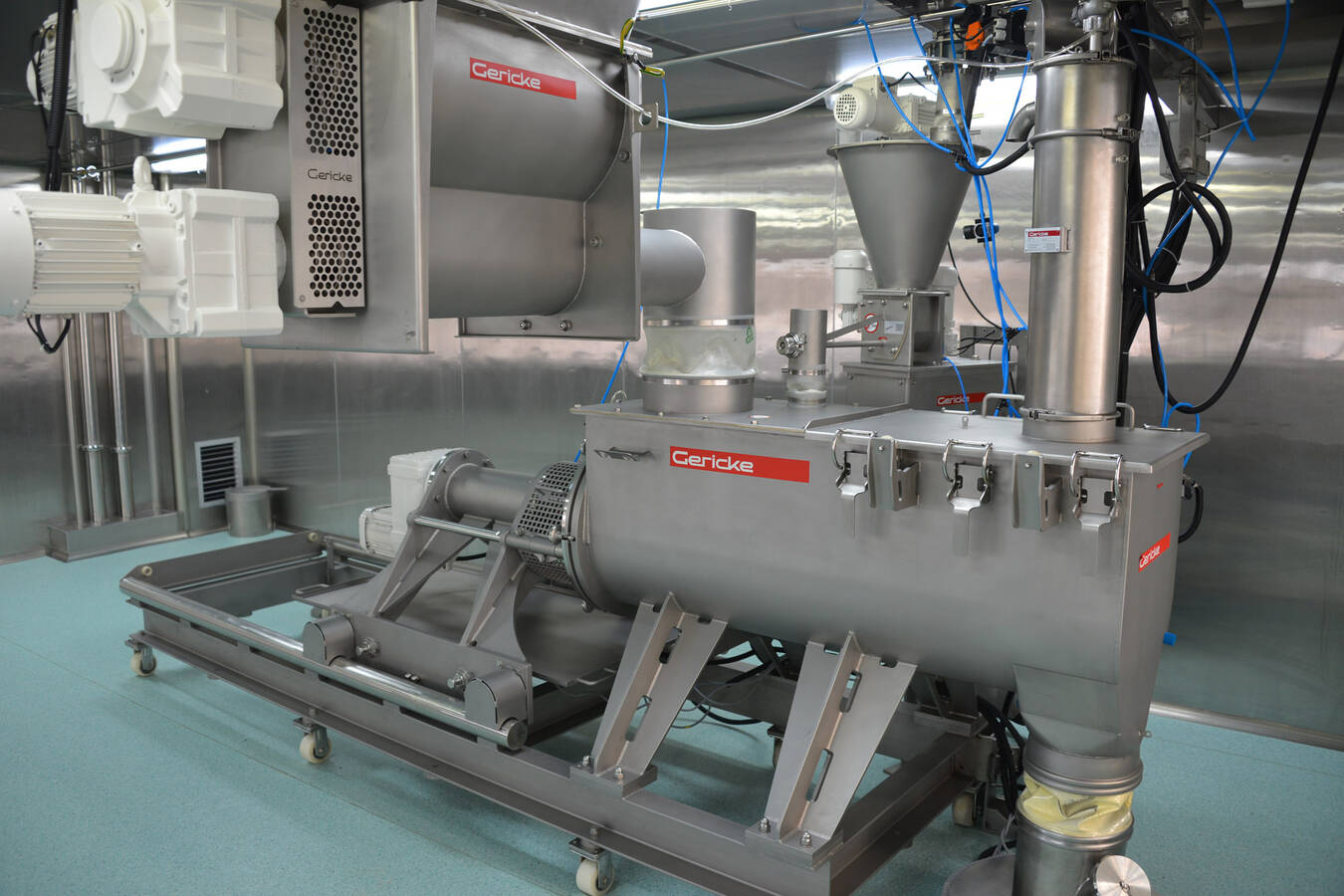

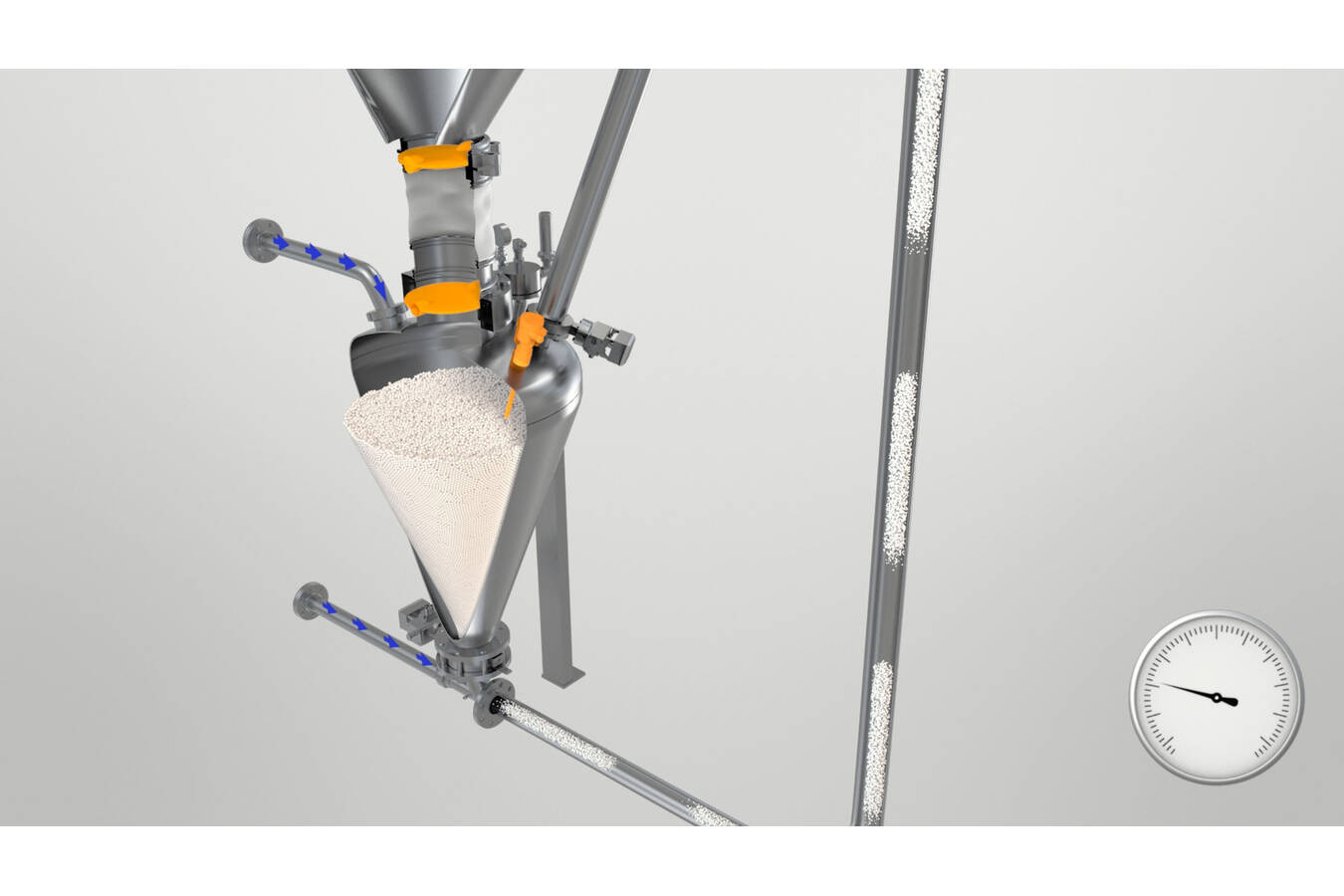

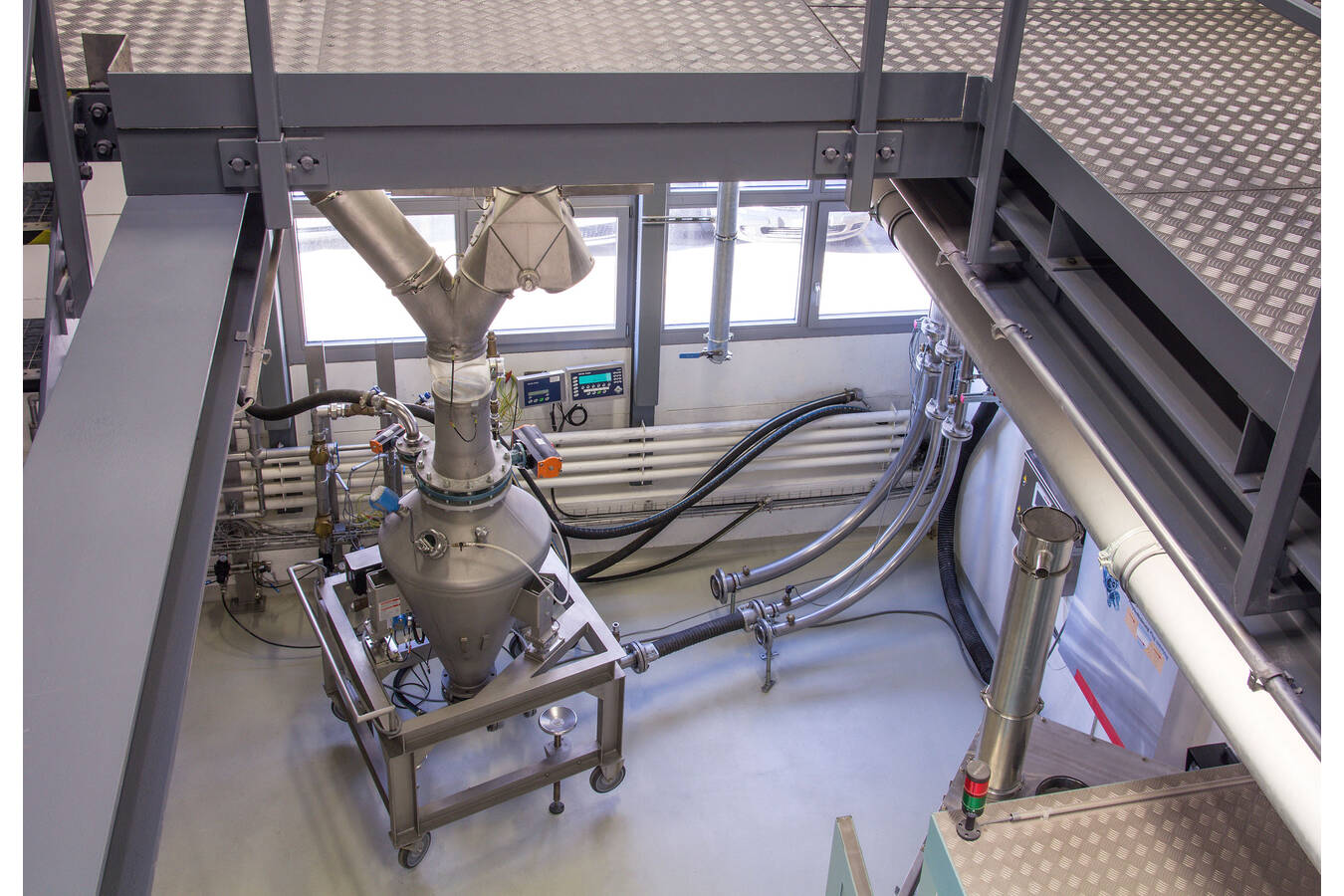

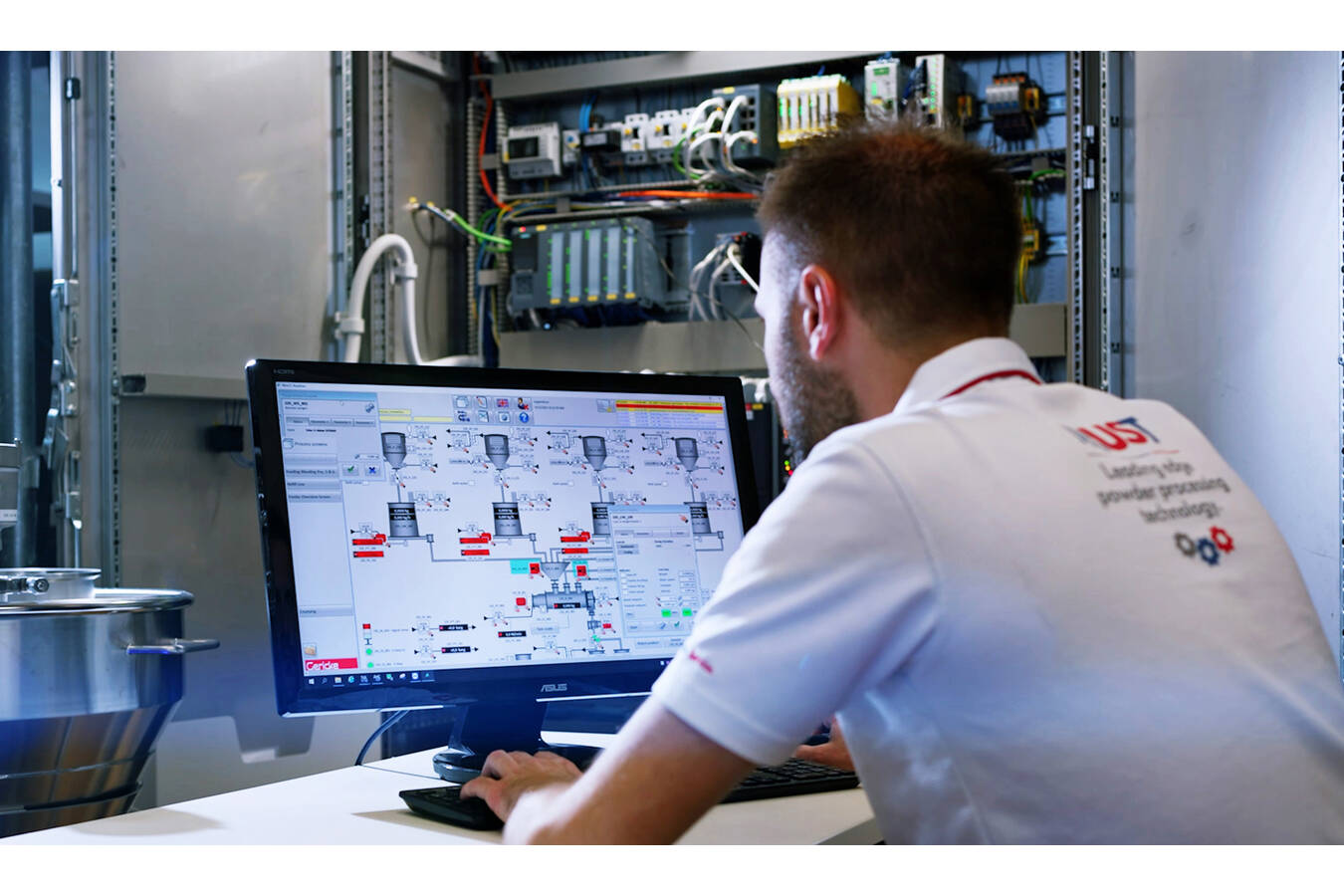

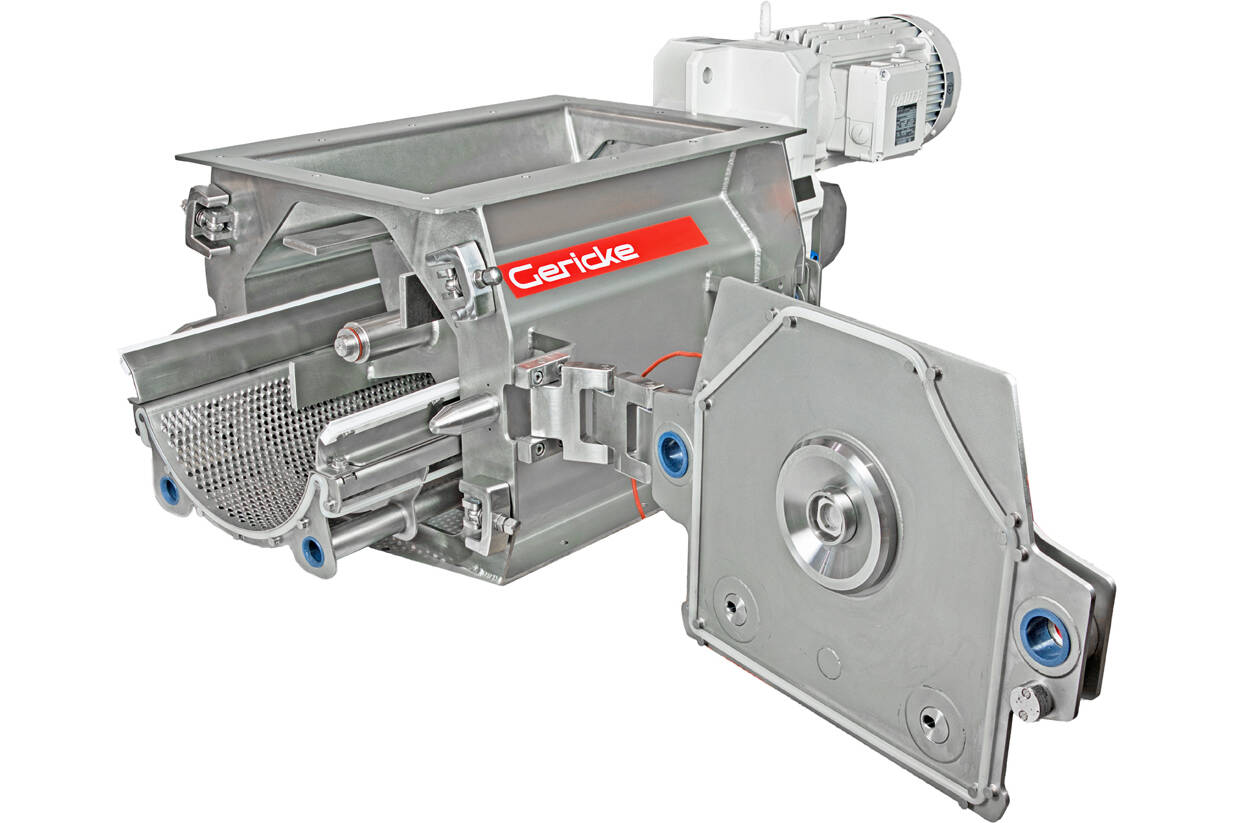

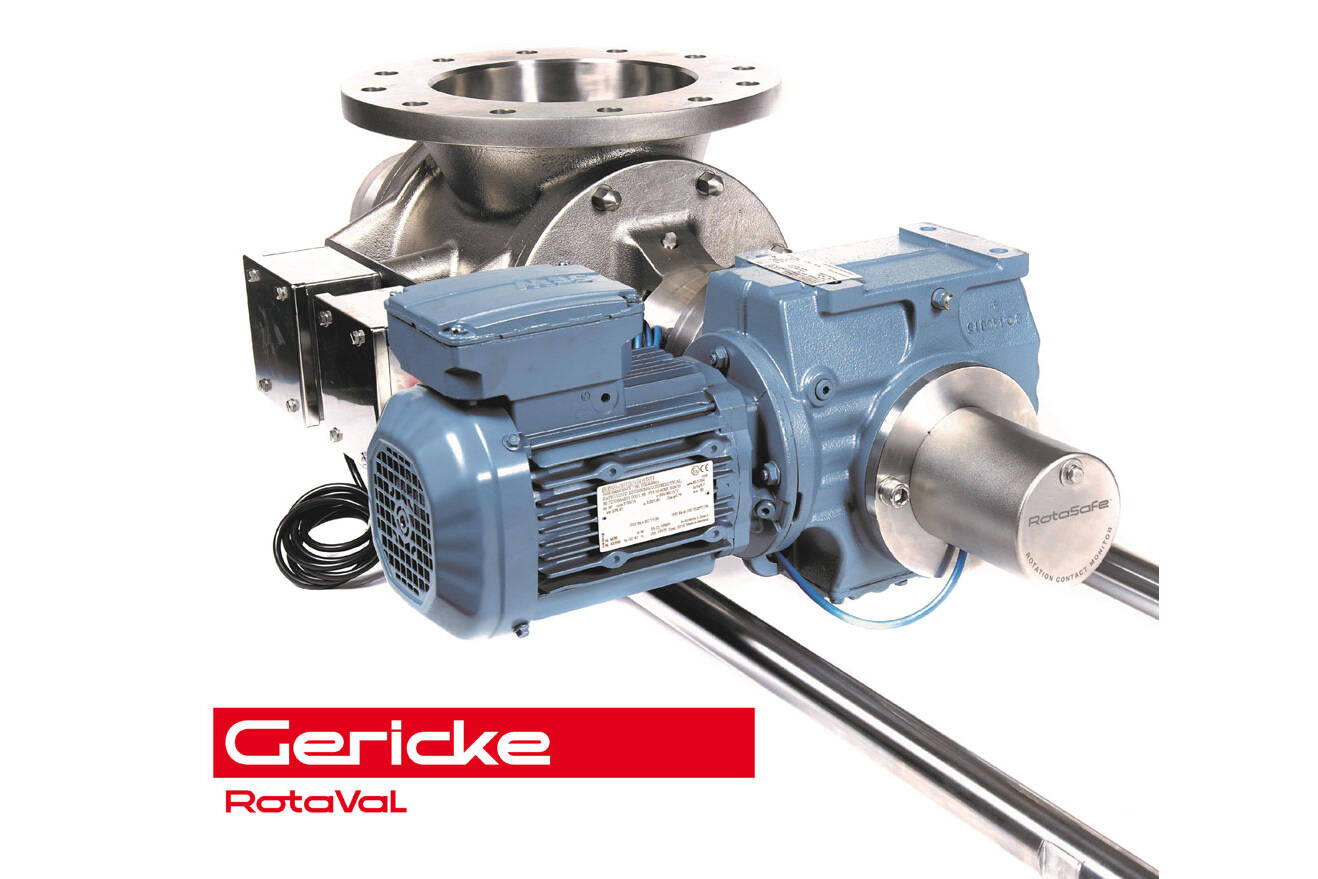

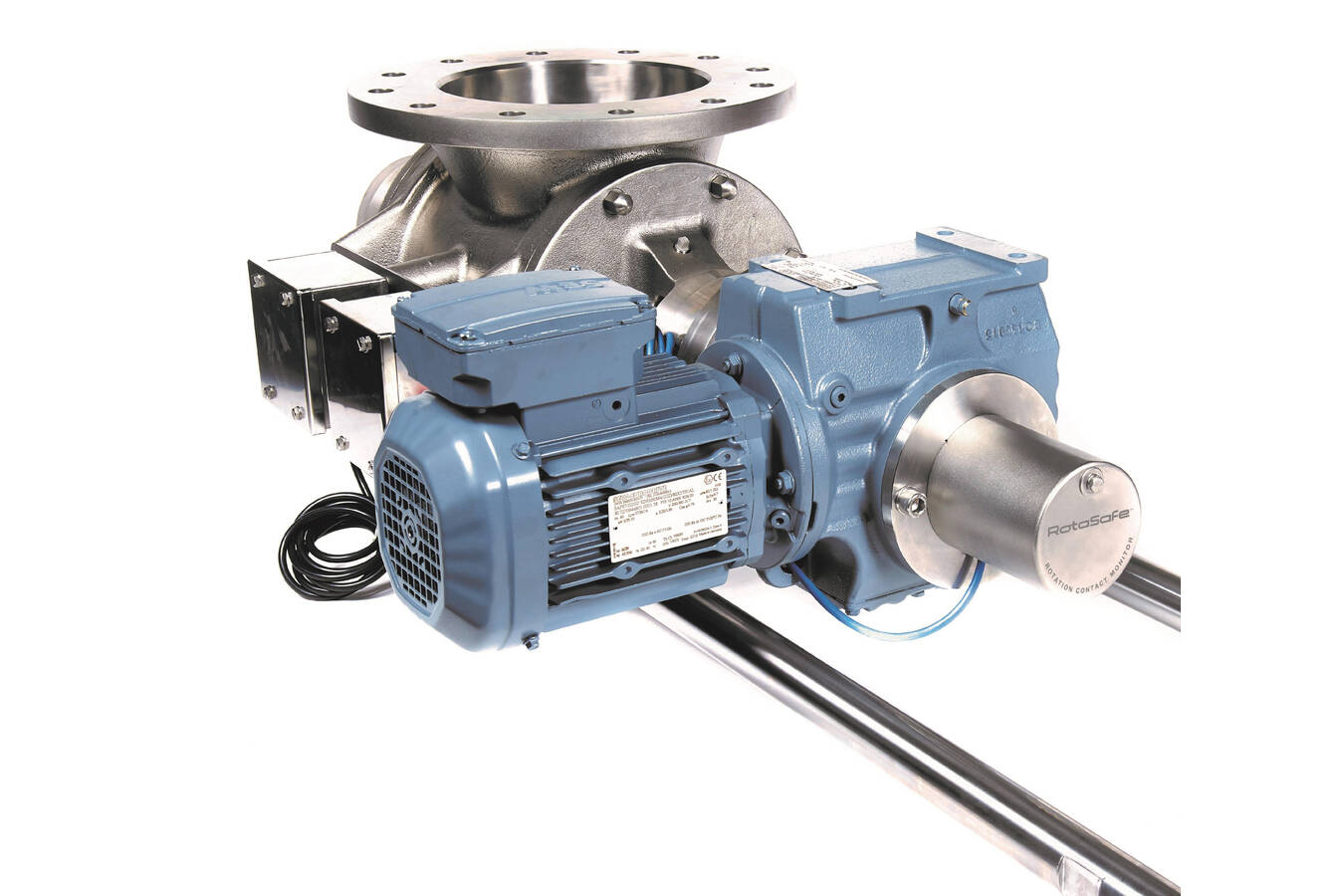

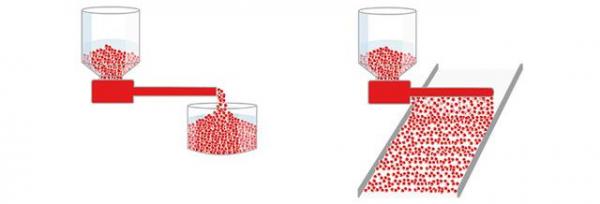

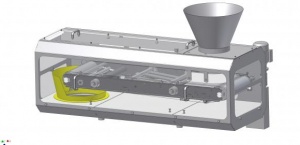

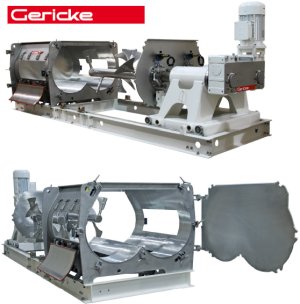

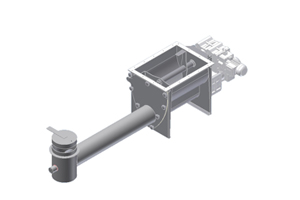

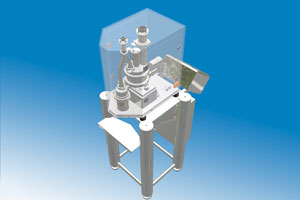

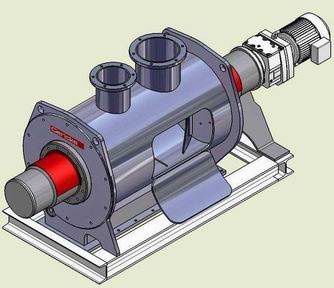

We manufacture machines and systems for process engineering, in particular pneumatic conveying systems, dosing and mixing systems. Our customers include renowned companies in the food, chemical, building materials chemical and pharmaceutical industries.

Products, services

Mixers, mixing, Cereal systems,

Show more