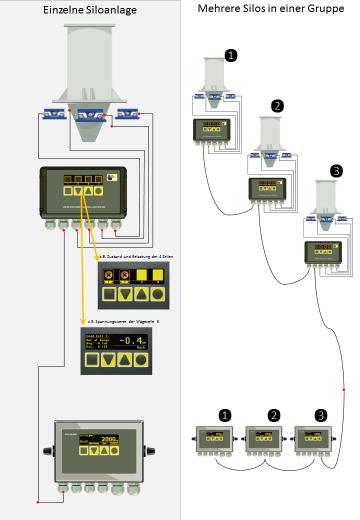

Load Cells - Load Cells, weighing assemblies, Load Cell, Silo scale, Silo weighing, hopper weighing, weighing technology, retrofitable weighing systems,

Solid flow measurement - belt scales, weight feeder, gravimetric feeders, dusttight scales, solid flow meter, Impact meter, impact scales

weighing, batching - Mass flow meter, Amplifier, batching electronic, solid flow meters, in- process measurements, flow meters

Standard weighing systems - Platform scales

Crane Scales

Pallet Truck Scales

Weigh Beams