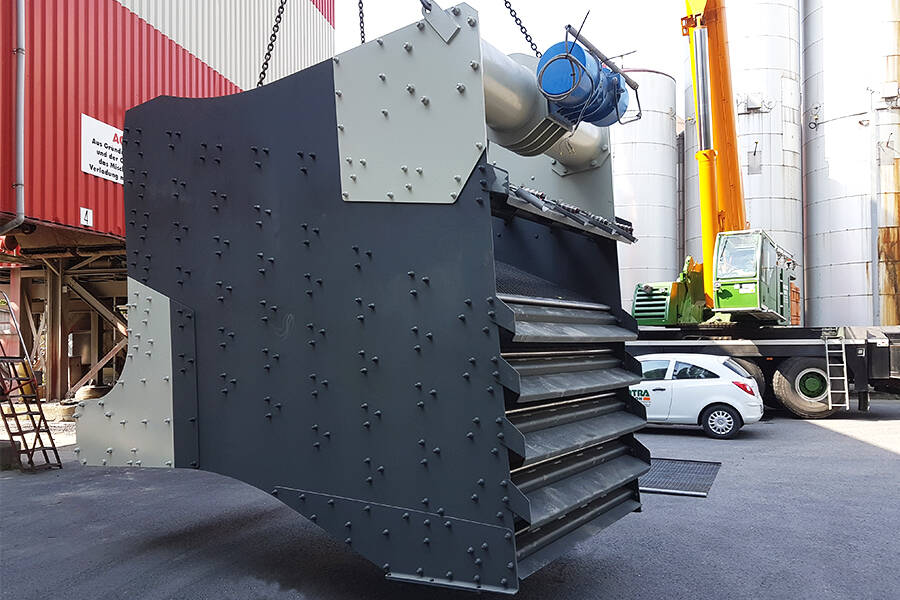

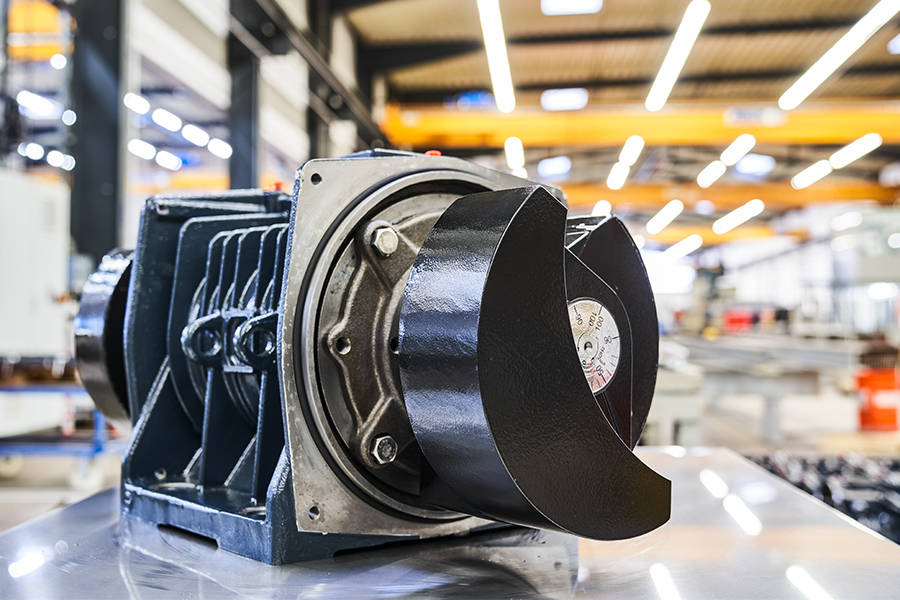

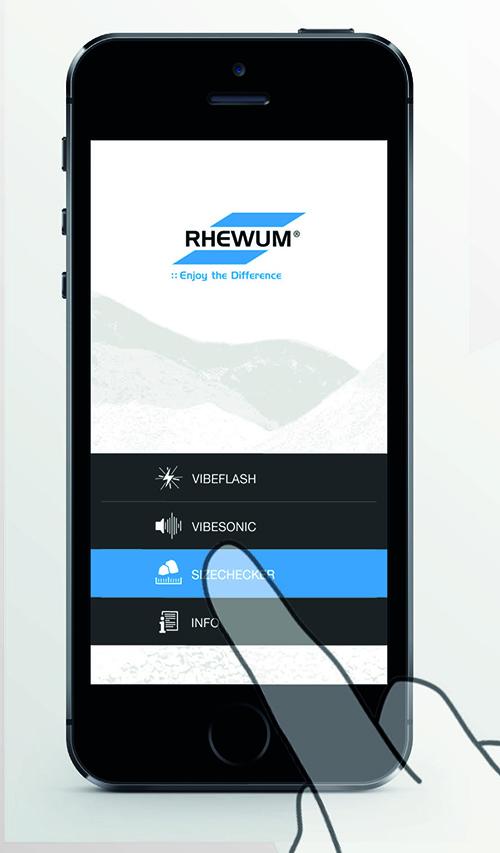

While others are just screening, we are seeing the big picture. Since its foundation RHEWUM has always been looking for the perfect solution. As the leading company in the field of industrial sieving technology we do not just provide screening machines, but the optimal separation of bulk materials that is perfectly tailored to your needs. We can achieve this through customized technology that offers unrivaled reliability with the highest service and product quality.

Categories

Separation, sieving, filtering - Sieving, sieves -

Control sievesSeparation, sieving, filtering - Sieving, sieves -

Disc sievesSeparation, sieving, filtering - Sieving, sieves -

Drum sievesSeparation, sieving, filtering - Sieving, sieves -

Flat screensSeparation, sieving, filtering - Sieving, sieves -

Rotary sieves

Show more

Categories

Separation, sieving, filtering - Sieving, sieves -

Control sievesSeparation, sieving, filtering - Sieving, sieves -

Disc sievesSeparation, sieving, filtering - Sieving, sieves -

Drum sievesSeparation, sieving, filtering - Sieving, sieves -

Flat screensSeparation, sieving, filtering - Sieving, sieves -

Rotary sievesSeparation, sieving, filtering - Sieving, sieves -

Shake sievesSeparation, sieving, filtering - Sieving, sieves -

Vibratory sieves