CADFEM is one of the pioneers in the application of numerical simulation in product development. We are one of the largest European providers of computer-aided engineering, a long-standing sales partner of the leading software manufacturer ANSYS, Inc. and ANSYS Elite Channel Partner with 130 ANSYS specialists.

Simulation makes a lot possible today. But because software alone does not guarantee simulation success, we offer everything that matters from one source: software and IT solutions. Consulting, support, engineering. Know-how transfer.

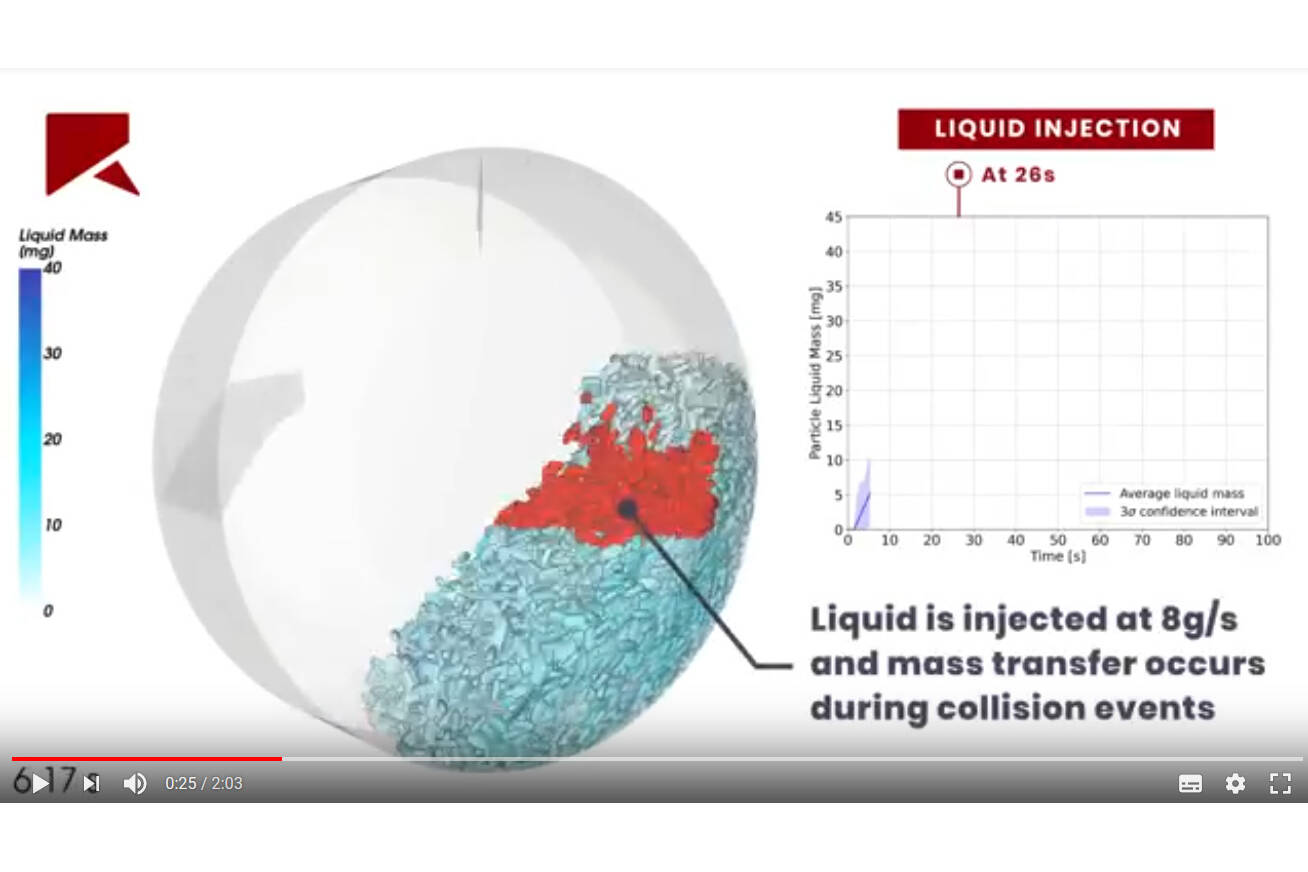

Our Rocky software enables precise predictions of particle behaviour by analysing media flows and energy absorption rates. Wherever large quantities of particles and bodies, regardless of their size, shape, material and adhesive force, are set in motion in pouring, mixing, slipping or flow processes, ROCKY can help to understand and specifically improve processes.

Translated with (free version)