Bulk solids handling courses - identify the problem, learn the solution. We offer online learning, face to face courses with practical workshops or in-company courses.

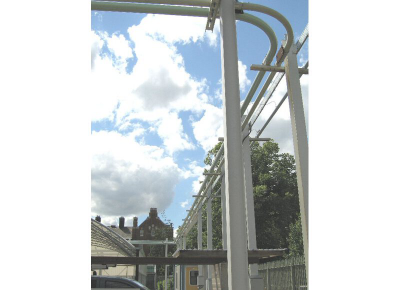

Pneumatic conveying - Consultancy and education services; Research projects. On-site pilot plant with pneumatic conveying pipelines.

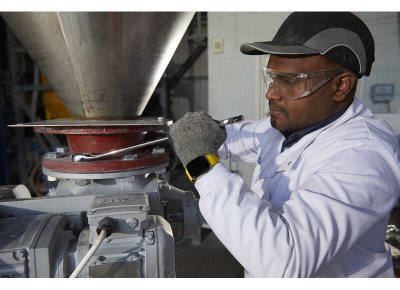

Discharge of Powders - Consultancy and education services; Research projects. Specialist equipment on site to identify issues with storage and discharge of bulk materials.

Expert witness services - For companies involved in litigation, arbitration or adjudication matters, we can provide reports, analyses, ’forensic engineering’ or court appearanc

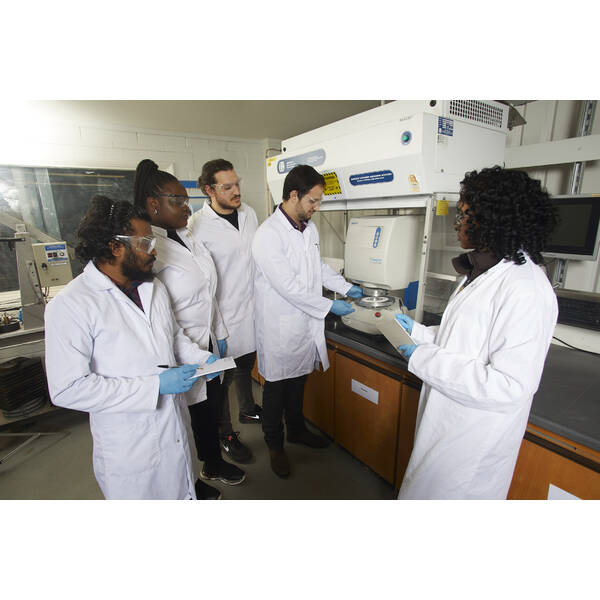

Powder Flow Properties - Consultancy and education services; Research projects. Powder testing facilities.

Plant Design services - The greatest risk to plant performance for end users is to assume a constant form and behaviour for a given bulk solid throughout the plant.

Particle shape analysis - Consultancy and education services; Research projects. Specialist equipment available

Quality control - Consultancy and education services; Research projects.

Bulk material handling - Independent expertise and cost-effective solutions to industrial problems

Hoppers and Silos - Independent expertise and cost-effective solutions to industrial problems