Which type of Rotary Valve should I select?

Short course: Rotary Valves; Design, Selection and Operational Issues 15 – 16 December 2020

On-line delivery: 14 :00 – 17:00 hrs UK time

Which type of Rotary Valve should I select?

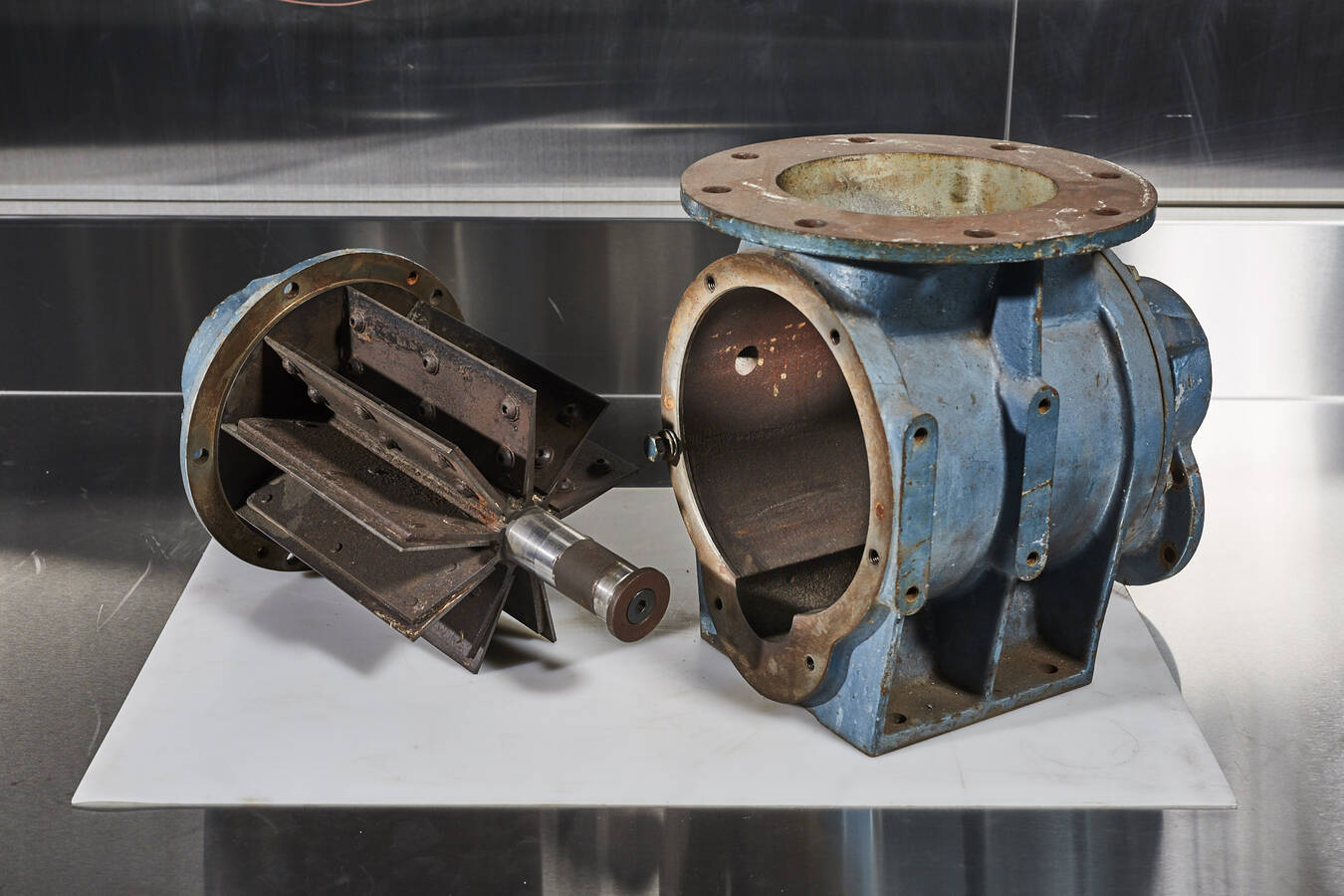

Faced with a large choice of rotor type, drive type, venting arrangements, bearing pattern, seal choice, clearances, cleaning features etc, never mind the choice of materials of construction, how does an engineer decide which type of rotary valve to select?

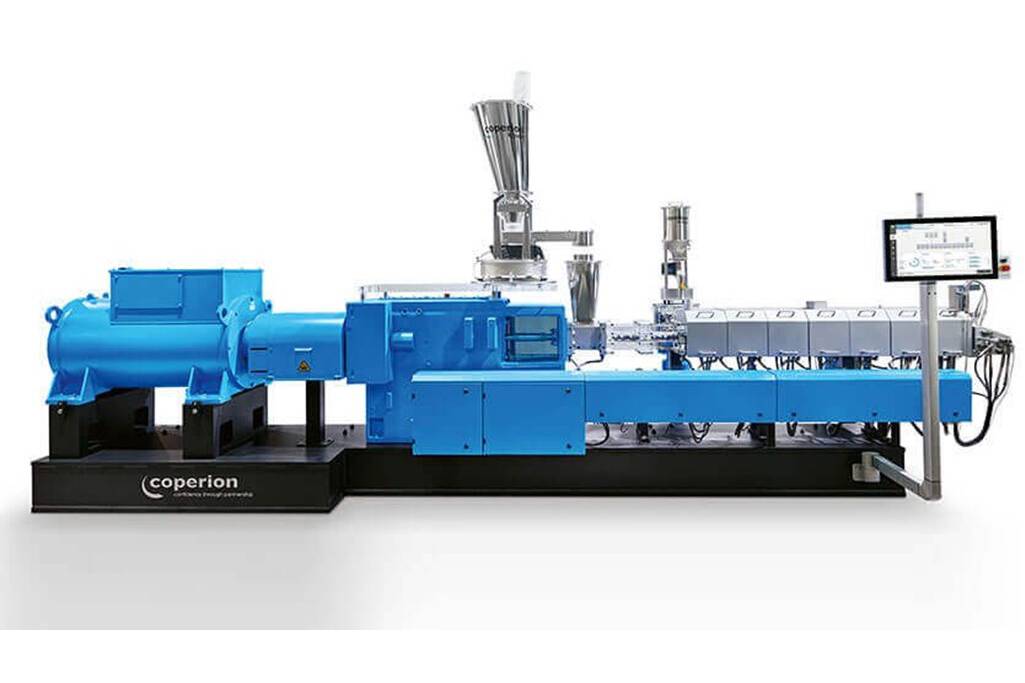

The course is aimed to help delegates understand the reasons for the different options and how to choose them and is recommended for engineers involved in the design of pneumatic conveying systems.

Held over two short sessions, we have prepared the following programme.

Programme

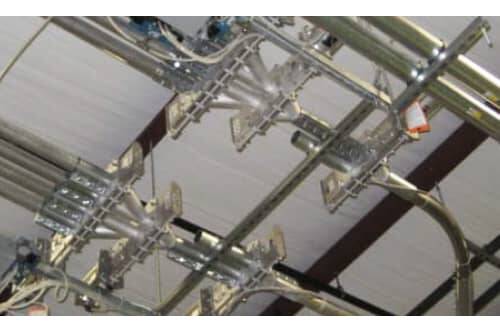

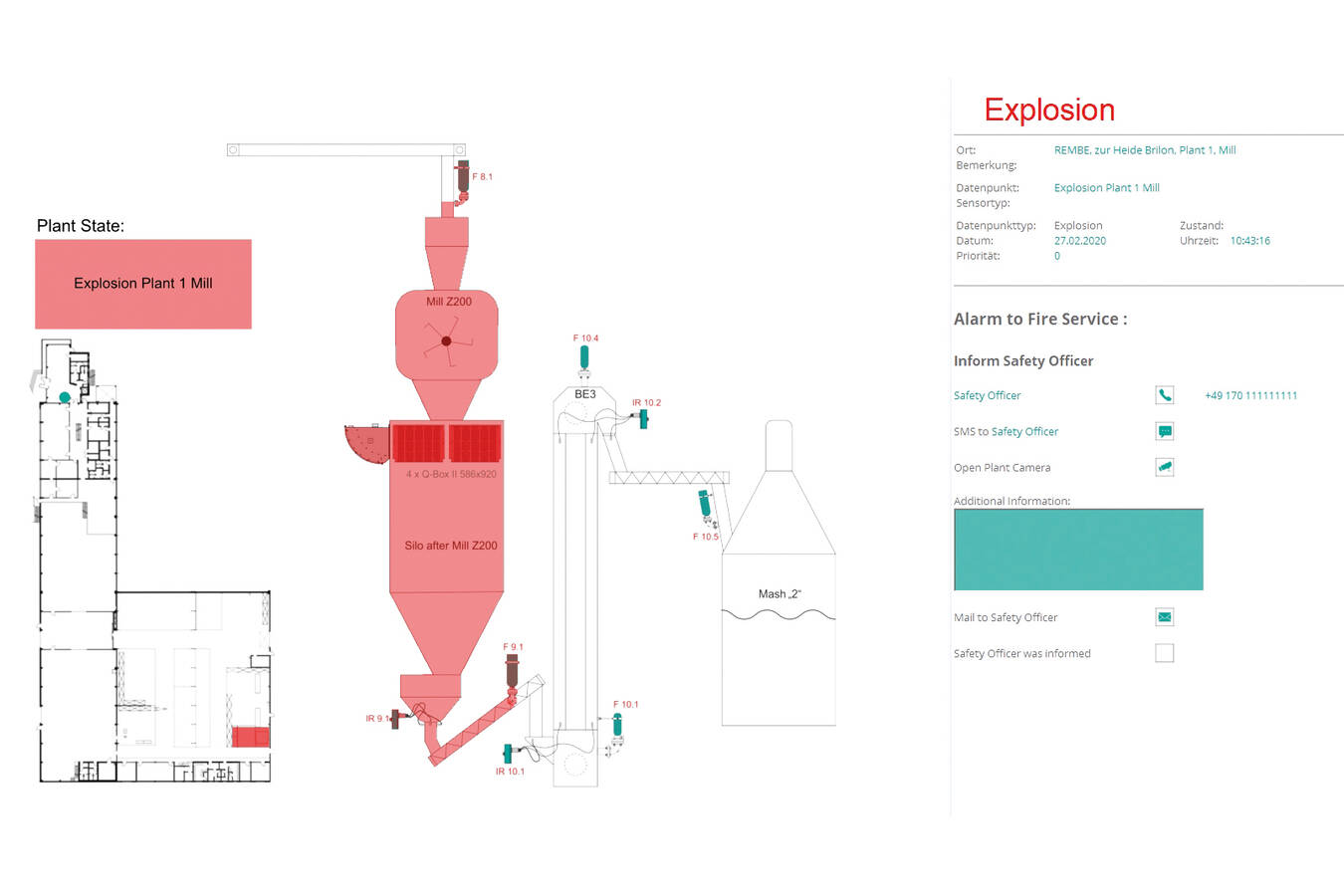

* Application areas for rotary valves, and their different demands (feeding, explosion protection, isolation etc)

* Basics of rotary valve performance – air leakage, feed rate etc

* Materials of construction linked to issues of wear and build-up

* Seals and bearings, options, functions and selection

* Special