Comprehensive characterization of Titanium dioxide- Webinars 10 & 11 Sep

From pigment to dispersion to coating From pigment to dispersion to coating - comprehensive characterization of TiO2 continues the Lum live webinar series and successfully helps our customers develop, formulate and bring new and improved products to market.

Titanium dioxide is an important white pigment, an important photocatalyst and is characterized by its high chemical resistance. It is used in a wide variety of products, e.g. in batteries, ceramics, food, inks, paper, plastics, sunscreen formulations, and wall paints. Its use is not always undisputed, especially with regard to TiO2 nanoparticles. However, there is a need for comprehensive and analytical characterization of the properties of pure TiO2, of coated particles and of finished products with TiO2 content.

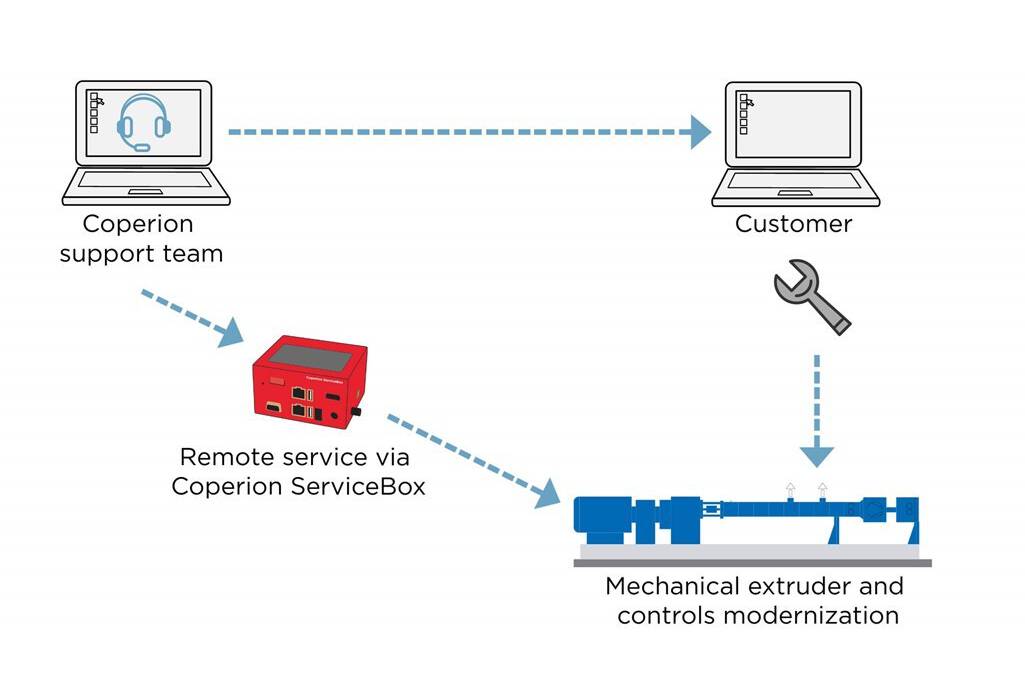

The LUM measuring devices can help you with many questions. Numerous references prove the successful use over more than 15 years.

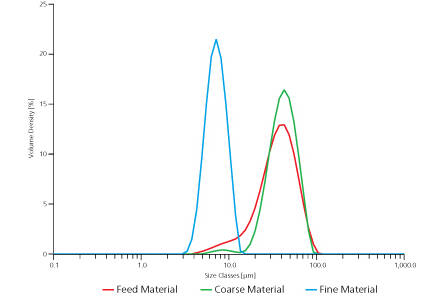

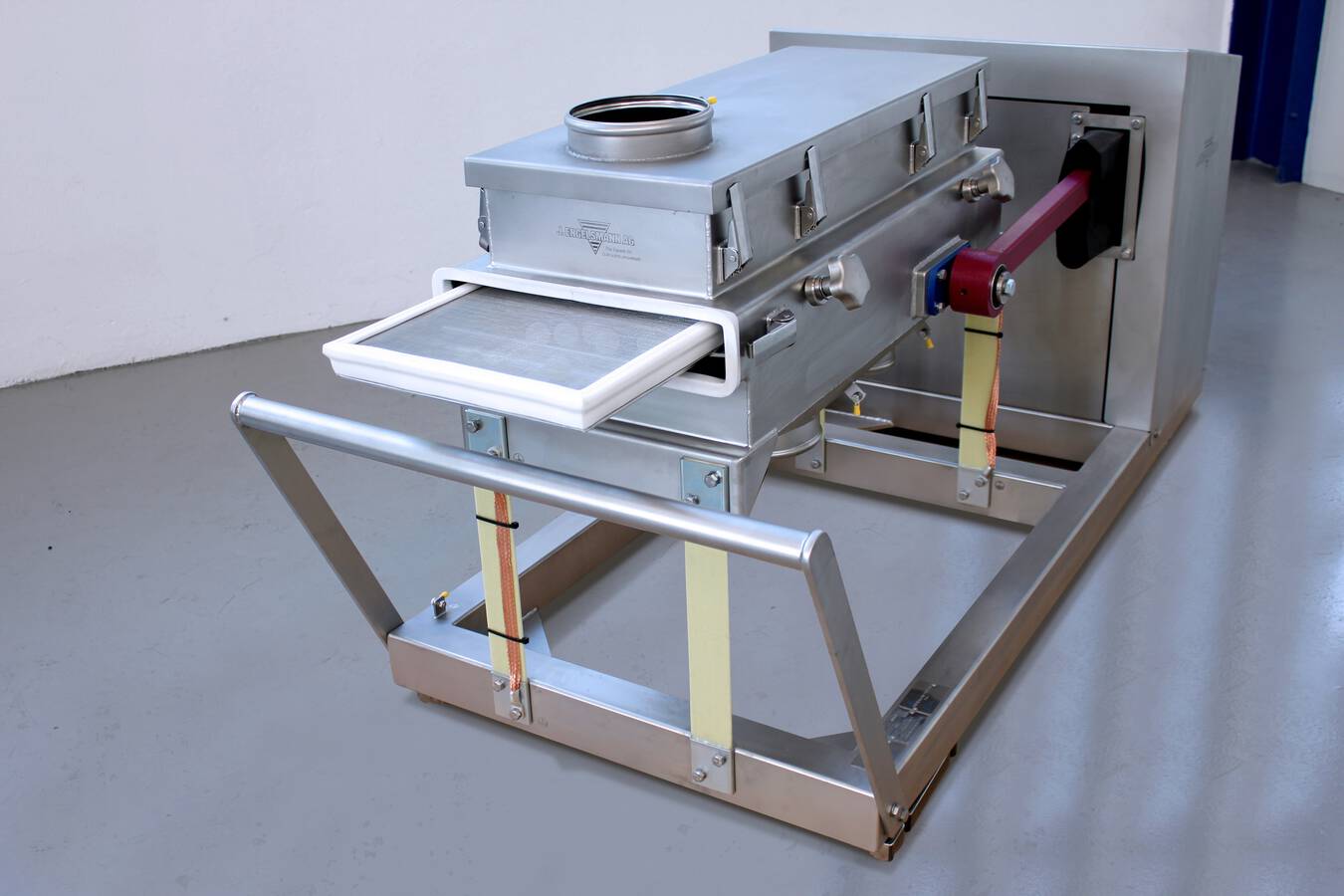

The examination of pulverized TiO2 is carried out with the LUMiReader X-Ray.

The LUMiSpoc optical single particle