17th German Belt Conveyor Conference March 10-11, 2021 online

Find 15 lectures, 21 international experts - the Conference will be performed as an online Conference for the first time. Dr. Yun Schüler-Zhou as the key-note speaker from Deutsche Rohstoffagentur, Berlin will give an important review about Chinas influence on the international raw materials market.

Interesting expert lectures will be given by Artel.Pro, Bedeschi Group S.P.A., Italien, ESI Engineering System International GmbH, Prof. Dr.-Ing. Frank Will, TU Dresden, ALFA Development GmbH, Lutze Group, Thyssenkrupp Industrial Solutions, USA, Sempertrans OfficeGermany, REMA TIP TOP Australia, Schade Lagertechnik GmbH, MTS Messtechnik Sauerland GmbH, RWE Technology International, Schulte Strathaus GmbH & Co KG, Martin Engineering

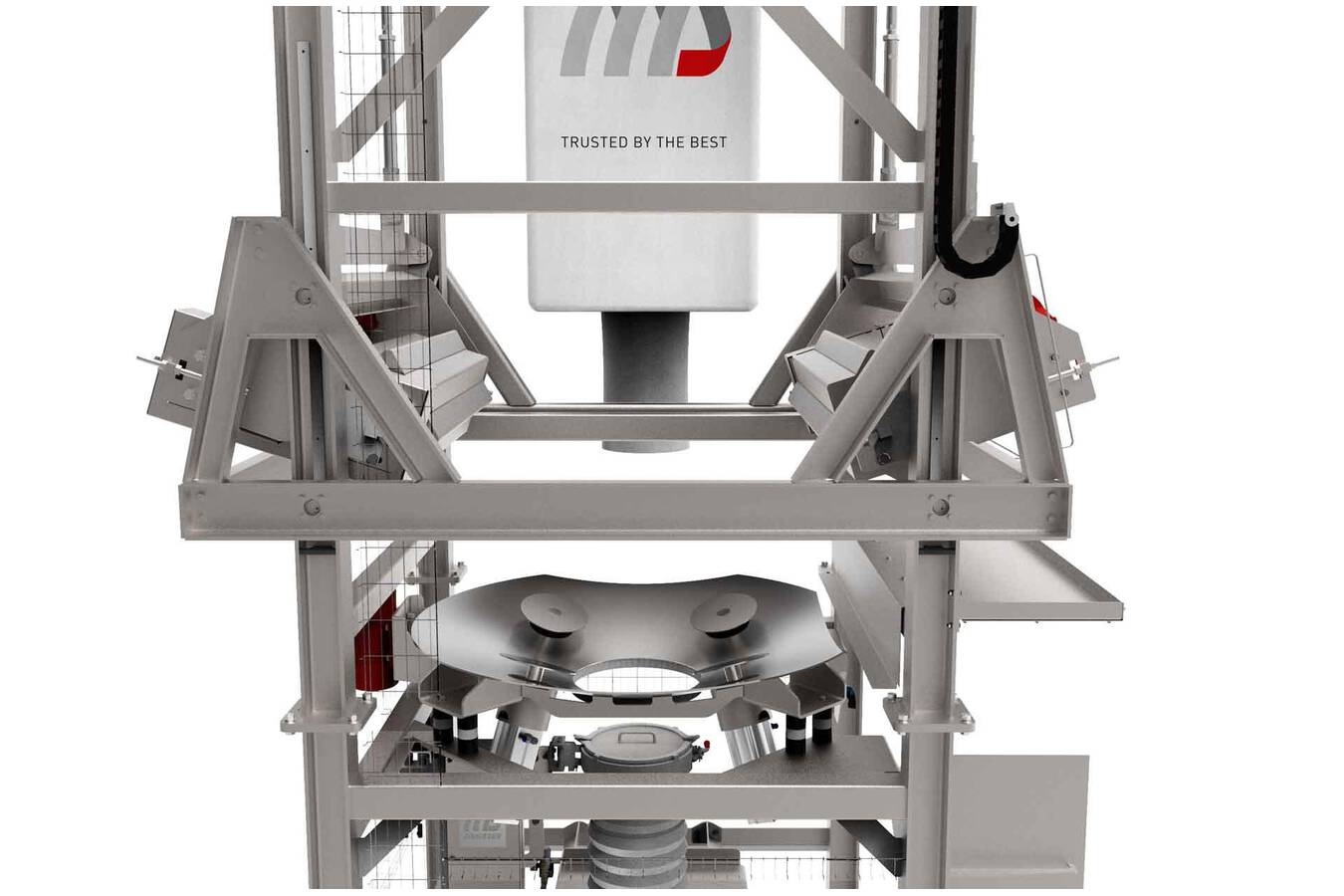

about Sibirian belt conveyor operation challenges, basics of efficient belt conveyor design and erection in inaccessable areas, development and use of digital twins and a current overview about VDI-Guidelines on conveyor-technology. Belt loading and integrated waging technology are topics as well as What does glass have in common with rubber? and wear protection