New control increases functionality of fume extraction systems

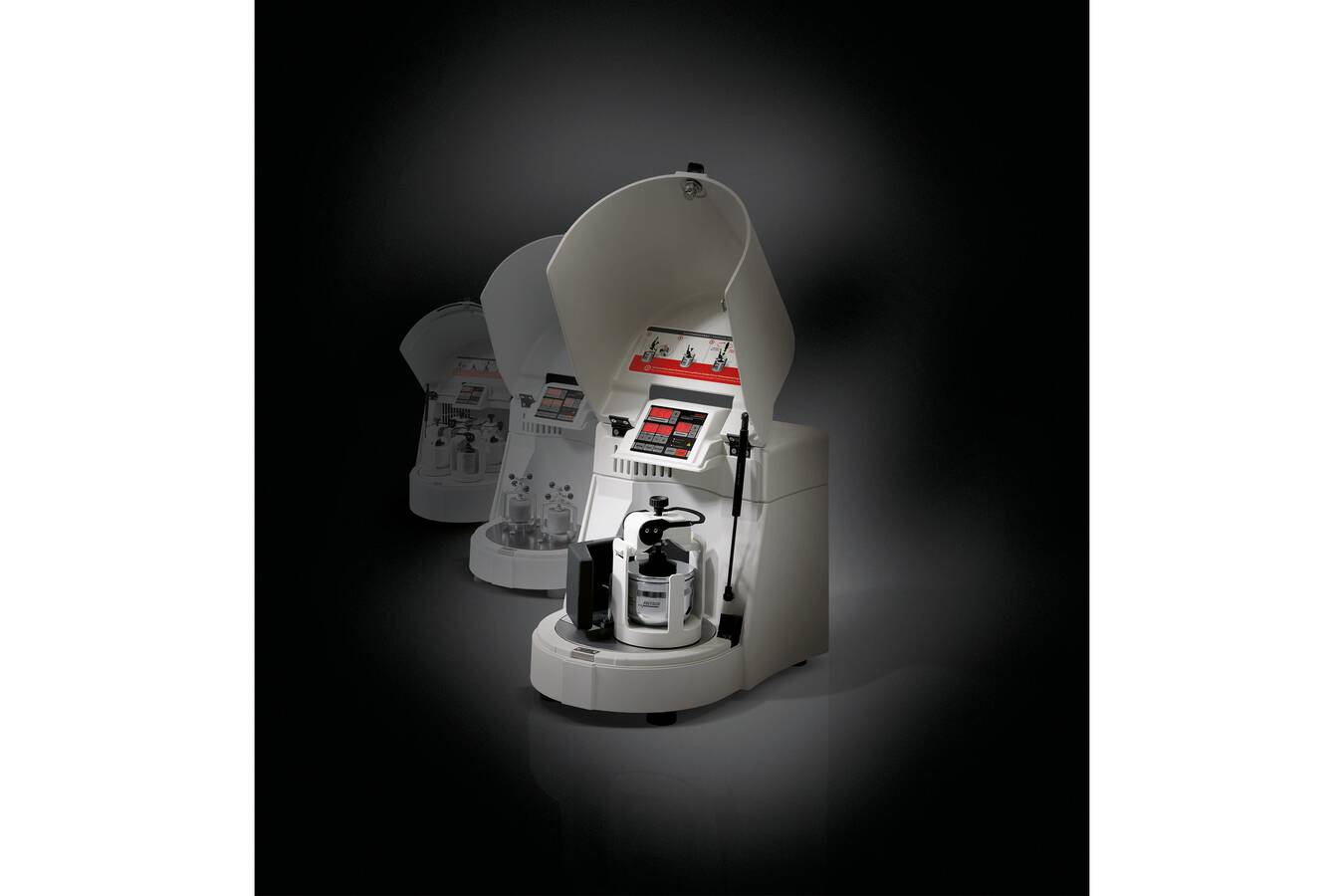

A new control enables the digital evaluation and control of the ULT extraction systems, which significantly expand their communication capabilities and thus offer users convenient evaluation and control options. ULT AG, vendor of extraction and filtration technology for air purification in manufacturing companies, presents a new system control. From now on, it will be integrated into the company’s cartridge filter systems, which will significantly expand their communication capabilities and thus offer users convenient evaluation and control options.

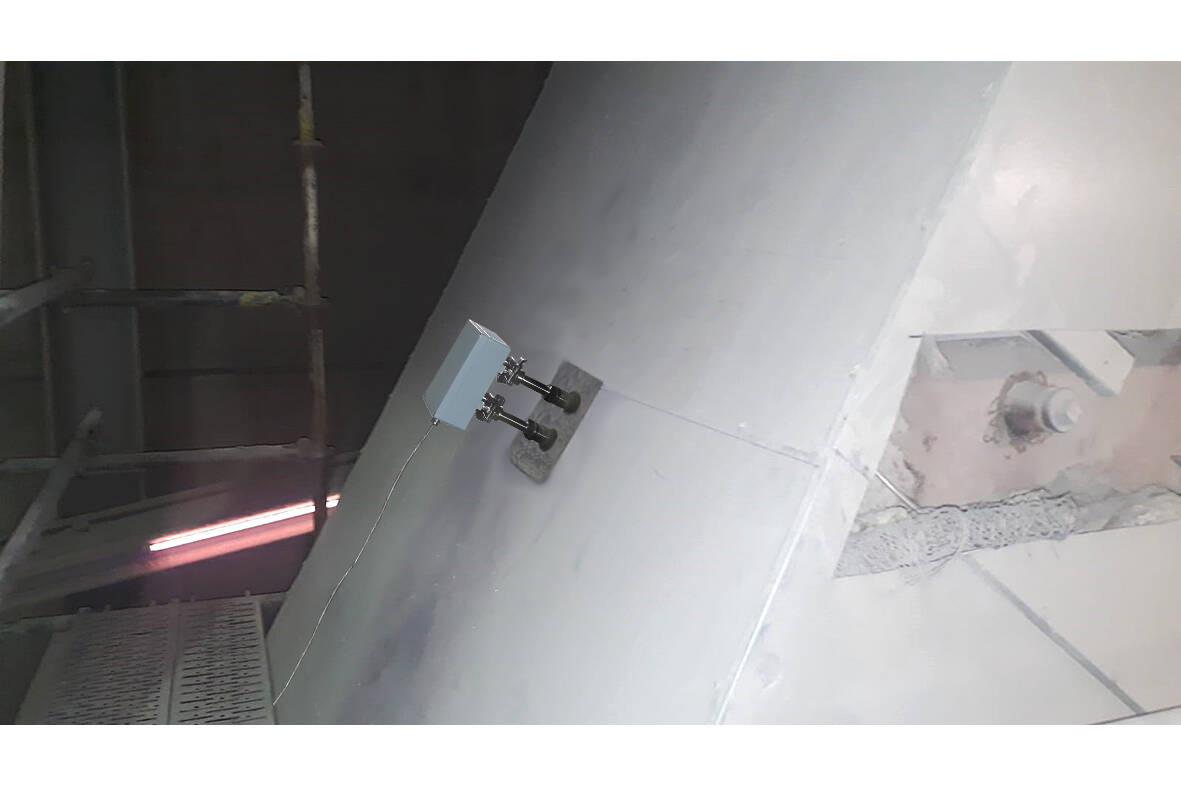

This ability is based on an integrated PROFINET interface, a device that enables communication with external systems, e.g., laser processing, painting or soldering systems, and, furthermore, the reading of operating states, such as filter occupancy, power, process gas temperature, error messages, and much more. ULT AG offers the PROFINET interface as a standard in its large fume extraction devices.

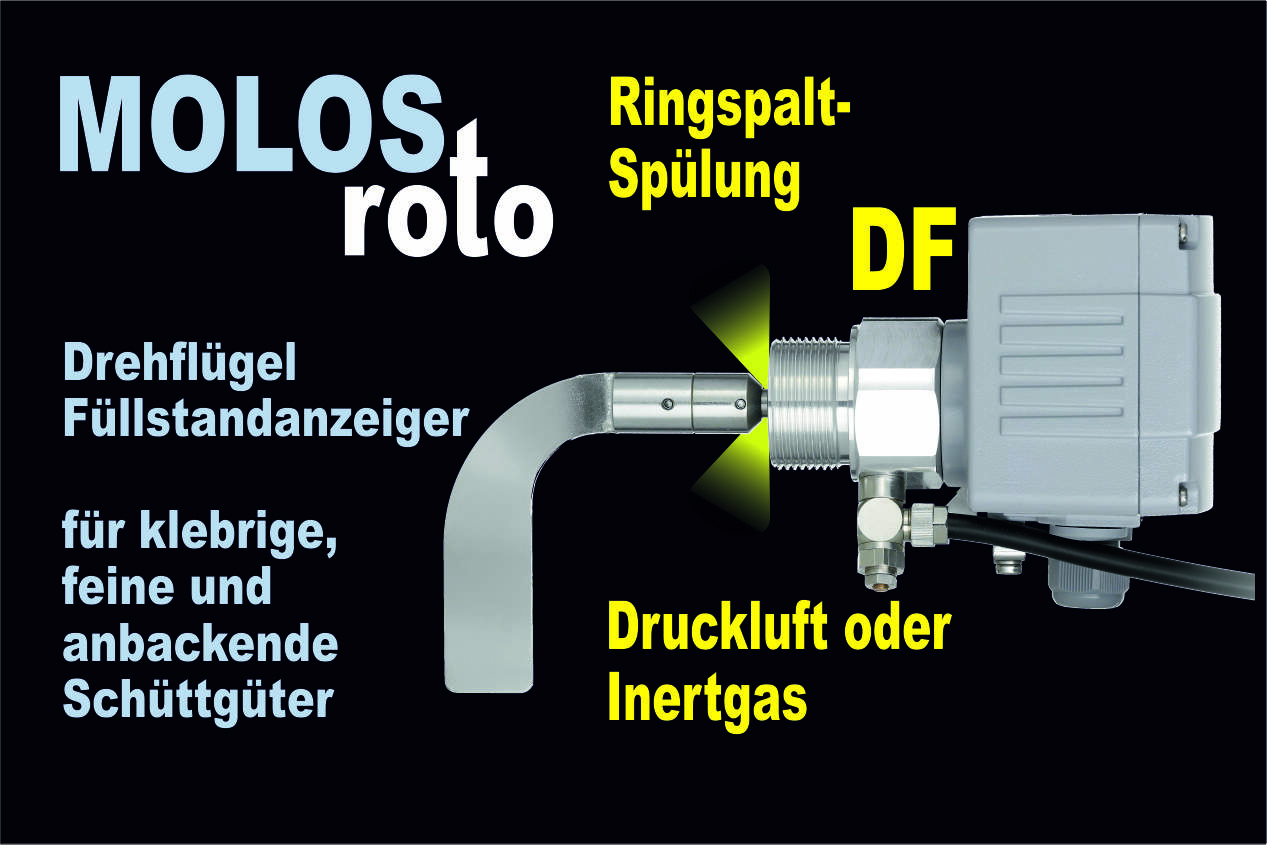

An essential part of the new system control is a display with plain text. This enables, for example, the reading of operating and system states, status messages for the extraction system and device parameterization. The display