Perfect belt alignment, 360 degrees movement

Sensitive correction without any potential for destruction, simple belt centering, the PrimeTracker.

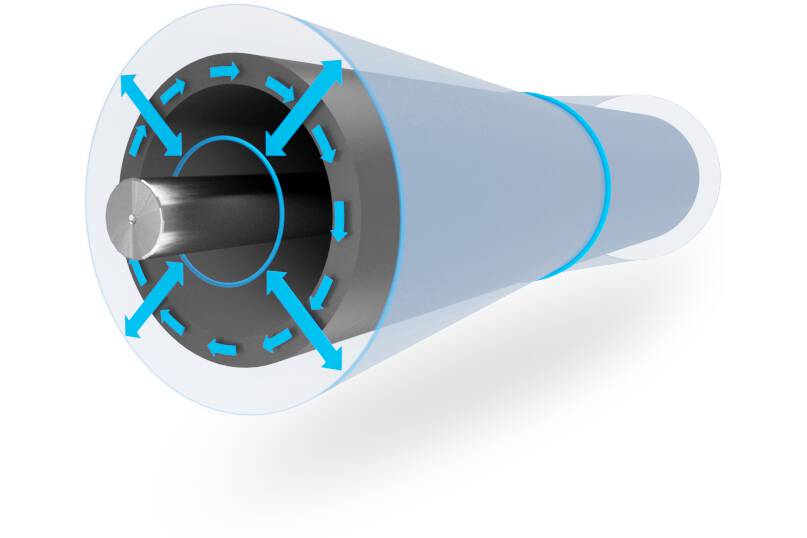

Plant operators know it, the annoying belt misalignment, because it is not rare. It occurs almost inevitably when drums and rollers are not well adjusted and aligned, or when they are worn, transverse forces act due to an asymmetrical task of the conveyed material or uneven belt connections are present and have to be compensated. To solve problems with misalignment on conveyor systems, there are numerous variants of different belt guide rollers that aim for the belt to run straight ahead.With this claim, the so-called PrimeTracker is now also being launched in the German market. Developed by the Swedish engineer Bertil Wahren, this special role has recently been part of the sales program of ScrapeTec Trading GmbH at his express request. The partnership is no coincidence, because the experienced technician Wahren and the specialists from ScrapeTec have been in a lively professional exchange for several years. What both sides have in common is that they leave well-known main tracks in their developments in order to find different, and ultimately better, ways of solving problems. It was against this background that the PrimeTracker was created, and the developer spent a good five years working on it. At the beginning there was the answer to the question why some belt centering systems tend to cause damage rather than benefit and / or even destroy themselves. His conclusion: the conical roller is to blame. If there is a difference in diameter between the thicker central part and the side areas of the tape guide roller, the speed of rotation is determined by the central part, which leads in relation to a lower peripheral speed on the sides. If the belt runs crooked, the load on the sides is higher than that on the middle section, because the pulley rotates at two speeds at the same time. Sliding wear and abrasion on the belt and pulley are the result. Bertil Wahren compares the situation with a car that drives with the brakes partially applied. His conclusion: It makes sense to use idle speed and, as with a car, to roll and steer at the appropriate speed instead of installing wear-and-tear braking to stay in lane.Based on this knowledge, the PrimeTracker was designed to be cylindrical. In order to bring the conveyor belt consistently in line as soon as a misalignment occurs, the PrimeTracker is loaded in the middle.

gert and can “swing out” completely freely in all directions in order to react sensitively and directly to the slightest misalignment. If the tape is running straight, the corrector simply functions as an idle roller. With conical variants, such a neutral idling does not work for the reasons listed.

Since the PrimeTracker has the same diameter over its entire width, it always has complete contact with the belt. Wear at the edge is prevented, belt and tracker are rewarded with a longer service life. A rubber central bearing and a sleeve seal for the soft suspension of the tracker shaft also contribute positively to the service life.

For the sake of order, it should be mentioned that other, largely cylindrical products are also available for correcting misalignment. However, according to the developer of the PrimeTracker, these work differently insofar as the axis restricts the movement possibilities of the rollers by means of an angle specification despite being centrally positioned. In this way, unlike with the PrimeTracker, unwanted friction at the edges cannot be prevented.