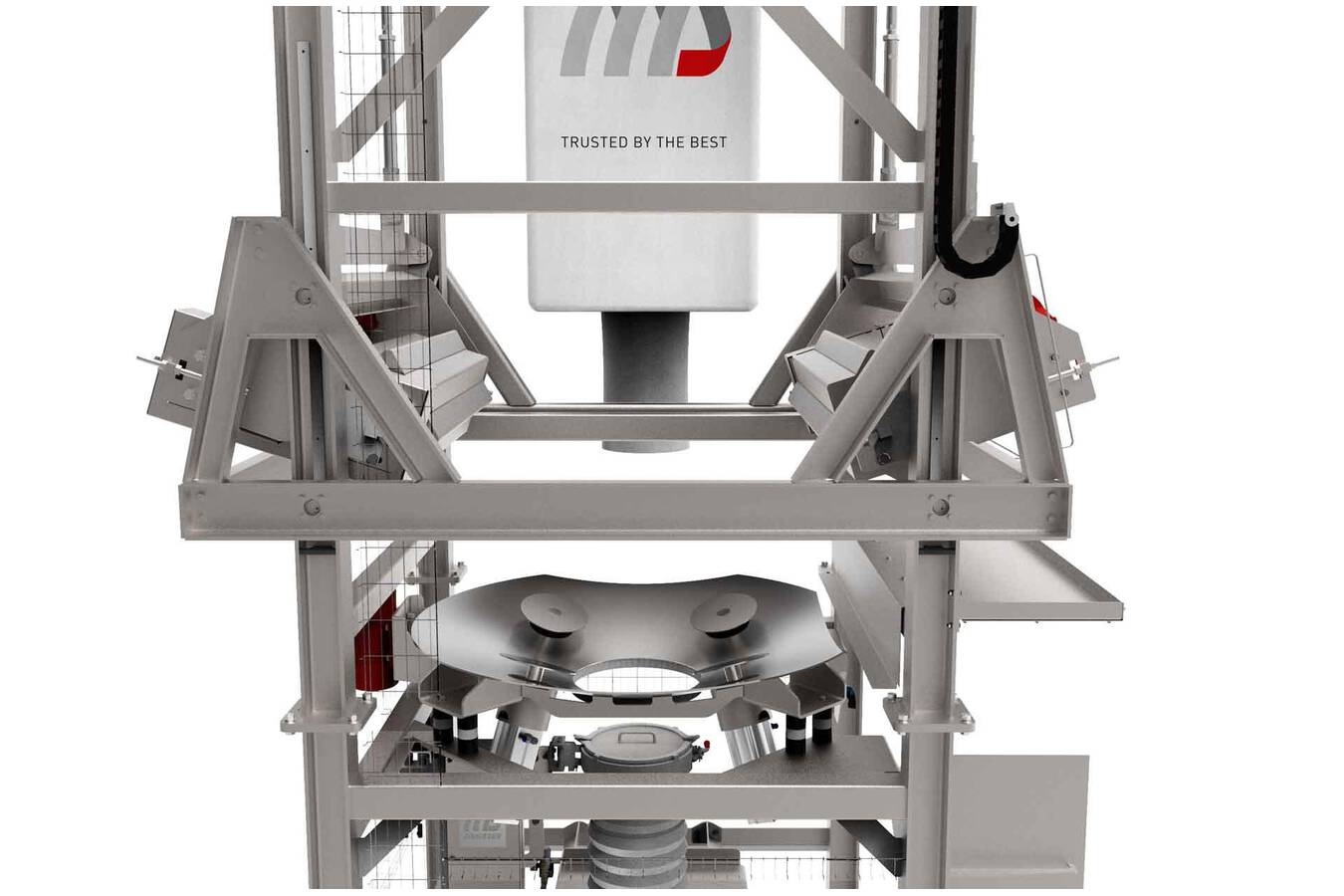

The Multisize Sample Carousel makes it possible to collect different sample sizes in one automated sampling process. Producers can now determine the order and frequency per sample size. Samples for various purposes (start sample, chemical sample, bacteriological sample, hour sample, batch sample) can now be collected in series fully automated. With exactly the right amount of product per sample.

Advantages

- More output per hour and fewer operators needed.

- Less error-prone and less product waste

- Automatic sampling of different sample sizes

- Possible to determine your own frequency, order, and sample size

Downtime reduced with the Multisize Sample Carousel

Every second that our customers’ production lines standstill is one too many. Together with our customers, we innovate production processes to maximize output and minimize downtime. Recently, a valued customer challenged us to reduce downtime per hour to a maximum of five minutes. In the sampling process, in particular, it turned out that we could save time. In close collaboration with the customer, our sampling carousel was further developed into the Multisize Sample Carousel.

Fully automatic sampling carousel

The requirements for food safety and product quality continue to increase. Testing product quality during the production process is therefore becoming increasingly important and intensive. Fortunately, you can greatly simplify and systematize this process with an innovative sampling carousel. For example, an automatic change of the filling position results in a smaller margin of error and less labor required.

Desired volume, weight and frequency

With our sampling carousel, it was already possible to automatically take batches of the desired volume and weight, at the desired frequency. With the Multisize Sample Carousel, you can now also take different sample sizes for various quality tests in series and fully automatically.

Specifications

- Current capacity ranges from 10 to 2000 g per sample

- Automatically collects up to 20 samples in different forms, without human intervention

- Hygienic design according to EHEDG criteria & easy-to-clean

- Stainless steel without internal (welding) seams

- Perfect integration with new and existing production lines

Sampling plan to a tailor-made carousel

In order to create a sampling process that is as efficient as possible, our engineers will draw up a sampling plan together with you. Perfectly tailored to your situation. Together we draw up a plan that meets the wishes and requirements of all departments (that are involved in the sampling process) of your organization.

Hygienic design and easy-to-clean

To be able to obtain representative samples, the cleanability of the carousel is essential. That is why all product-handling parts can be removed easily and without tools. The material certificates of these product-handling parts (e.g.: FDA and EC1935/2010) are supplied by default.

Integrate controls into your current processes

It goes without saying that our sample carousels have their own controls. If desired, this can be integrated within the upper control, where specific communication signals help to signal the status and possible malfunctions. This results in a foolproof sampling system. The sampling carousel is also available in an ATEX version and will be delivered according to your individual specifications.