Poeth BV

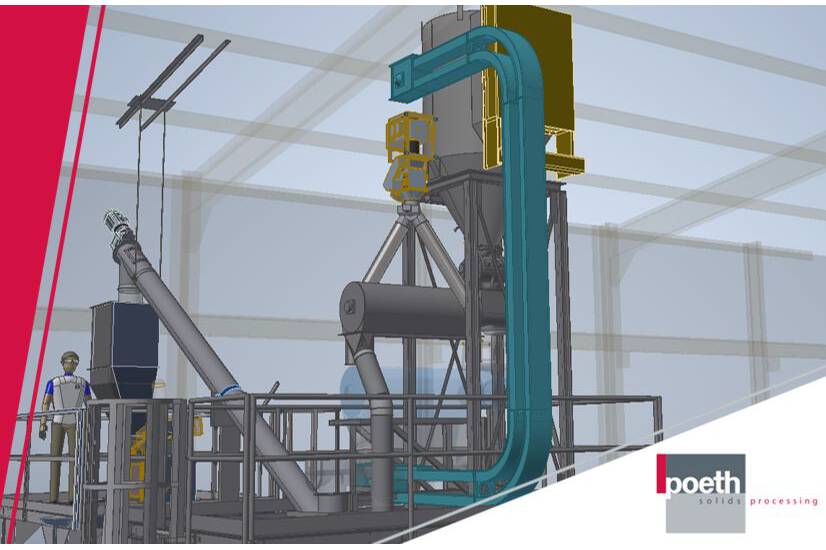

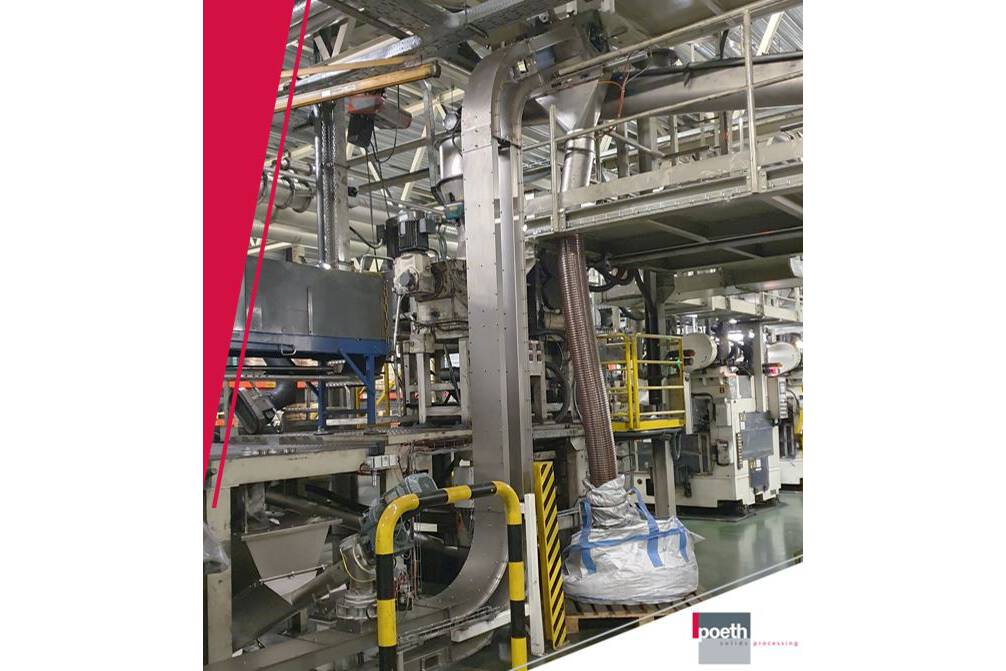

Poeth specialises in high-quality machines and production lines for processing a broad range of dry materials.

We develop, produce, and install all our machines and carry out all our projects with our own staff, allowing us to provide flexible and affordable tailor-made solutions for our clients.

First established in 1921, we have acquired a rich store of knowledge and experience in the agricultural and industrial sectors, and we are now a leading player in production processes for the feed, food, brewery, and bulk industrial sectors.

Industries

Poeth develops, produces, erects and commissions, sophisticated machinery and production lines for various processes in solids handling. Our knowledge and experience is mainly based on agri-industrial processes, since 1921.

Applications of Poeth machinery and process experience are found in food processing as well as f.i. in recycling of bio-mass. An important product is an extensive program of industrial dust-filters.

Products

Technological Solutions for Solids Processing: Our product range includes high-quality technology and service solutions for the handling, conveying and processing in different industries. We consult and support our clients during decisions on important investments with knowhow and experience. With our advanced filter program we help you to solve emission problems. Experience is available for a wide range of dusty products.