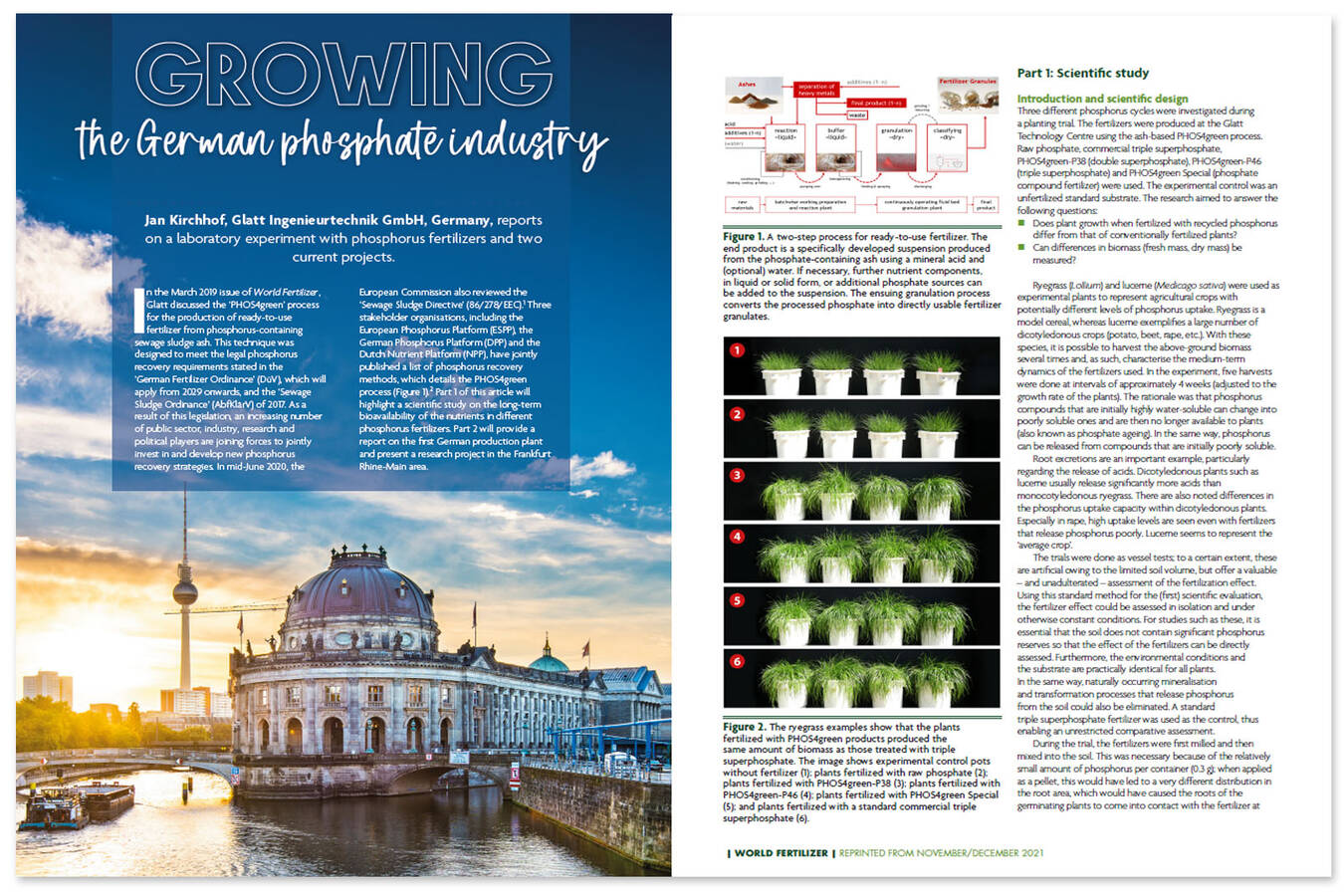

Using completely new technology, pigment specialists at Merck and Glatt Ingenieurtechnik’s technology and production experts have worked closely together to produce an innovative range of cosmetic pigments. The Darmstadt-based Merck Group placed an order for the development and construction of a plant based on chemical vapour deposition (CVD) after successful joint trials at Glatt’s location in Weimar. We interview the partner companies about the cooperation and the project.

EuroCosmetics: How did the cooperation between Merck and Glatt Ingenieurtechnik (GIT) to produce Ronaflux® pigments come about?

Dr Katarzyna Sztuka: Merck and Glatt have had a successful partnership for many years. For example, Glatt manufactures equipment for Merck’s Healthcare and Life Science divisions. Producing Ronaflux® pigments, which are cosmetic products, requires a special quality and purity standard. This infrastructure was already in place at Glatt or could be expanded quickly and cost-effectively. As a plant and process specialist for fluidised bed technology, Glatt had the relevant know-how required to set up a production plant for Ronaflux® pigments.

EC: What development and engineering services did Glatt Ingenieurtechnik provide?

Arne Teiwes: As well as developing the customised plant technology for Merck, we also built the entire process line at our technology centre. It’s owned by Merck, but we operate it on-site and act as a contract manufacturer of Ronaflux® pigments for them. Here, we’re combining our experience as process and application developers, equipment and plant manufacturers, GMP-compliant factory planners and contract manufacturers. We’re able to do this because we can literally unite all the required competencies for a wide range of industries “under one roof.” The Dryflux technology, for example, that’s used to produce the Ronaflux® pigments, was developed by Merck at laboratory scale and then scaled-up and optimised by GIT.

EC: What is it about Merck’s Ronaflux® pigments that sets them apart?

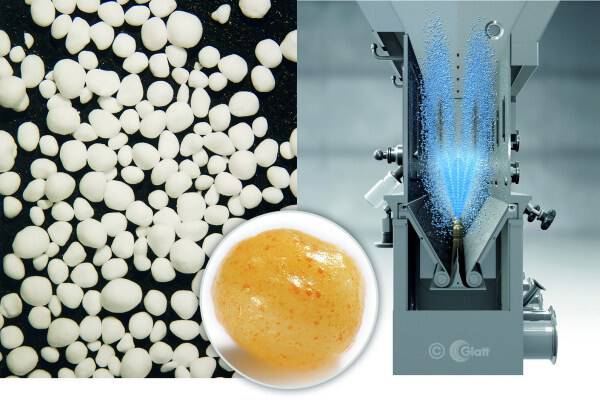

Sztuka: Owing to innovative technology, the Ronaflux® pigments offer a dramatic high colour intensity range featuring pronounced metallic optical effects; these are achieved without the use of metals. This striking, colour-intense look with a metallic allure reflects the current trend in colour cosmetics. At the same time, it’s necessary for manufacturers to meet stricter regulatory requirements and to ensure the stability of the colorants and pigments they use. With Ronaflux® pigments, which are based on an entirely new technology, customers can meet these challenges while achieving unique effects that are not yet commercially available.

EC: What special requirements are necessary to produce the Ronaflux® pigments?

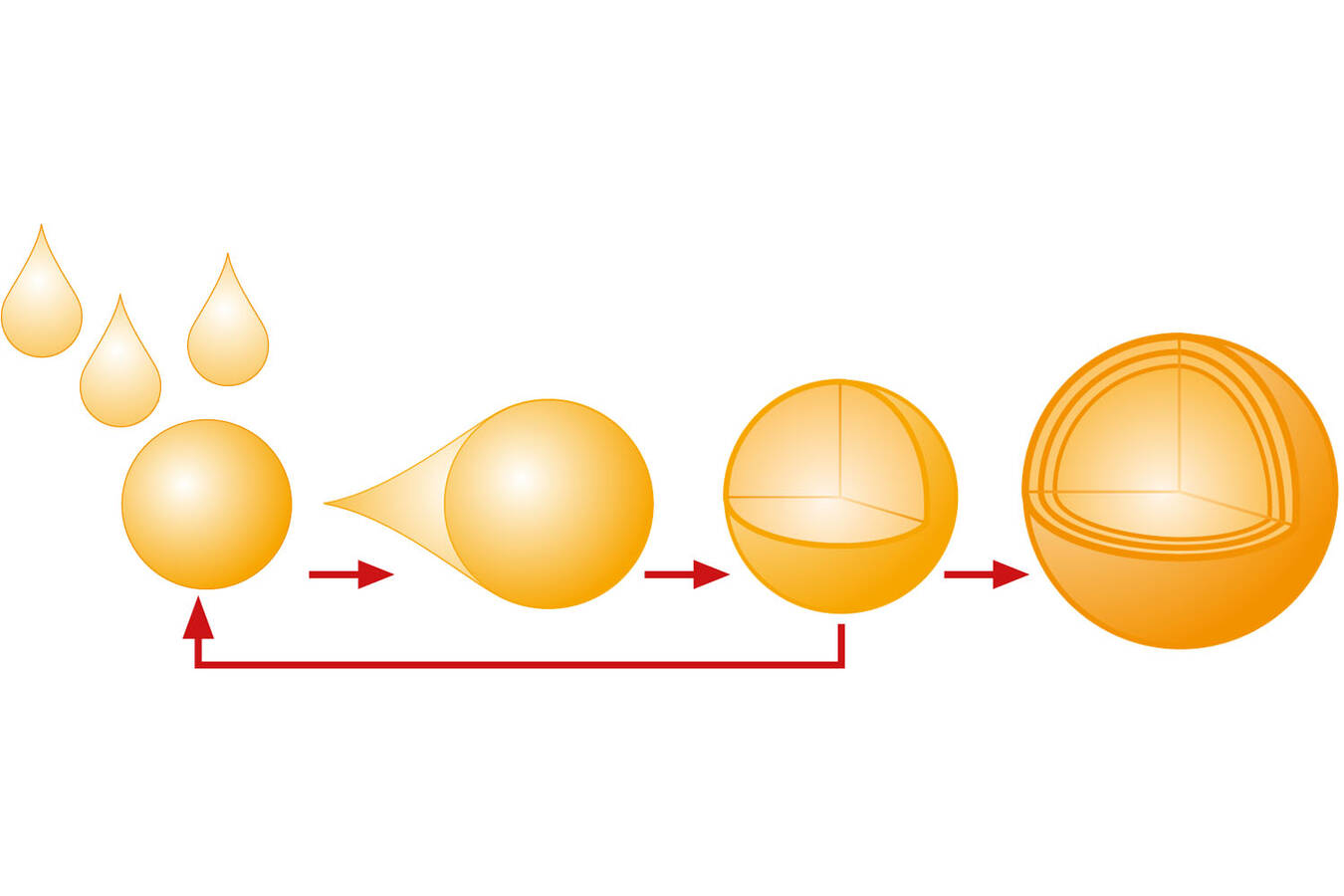

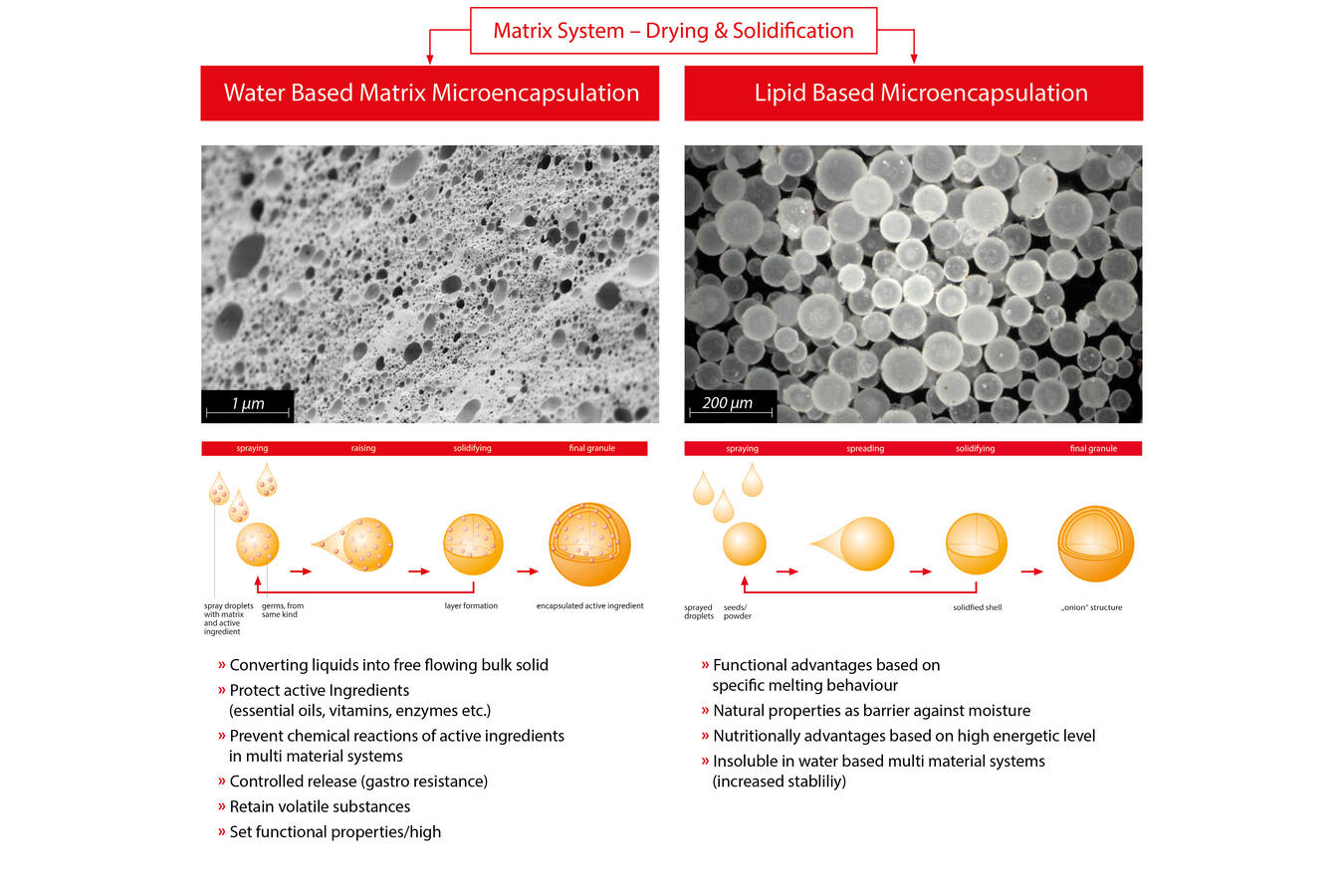

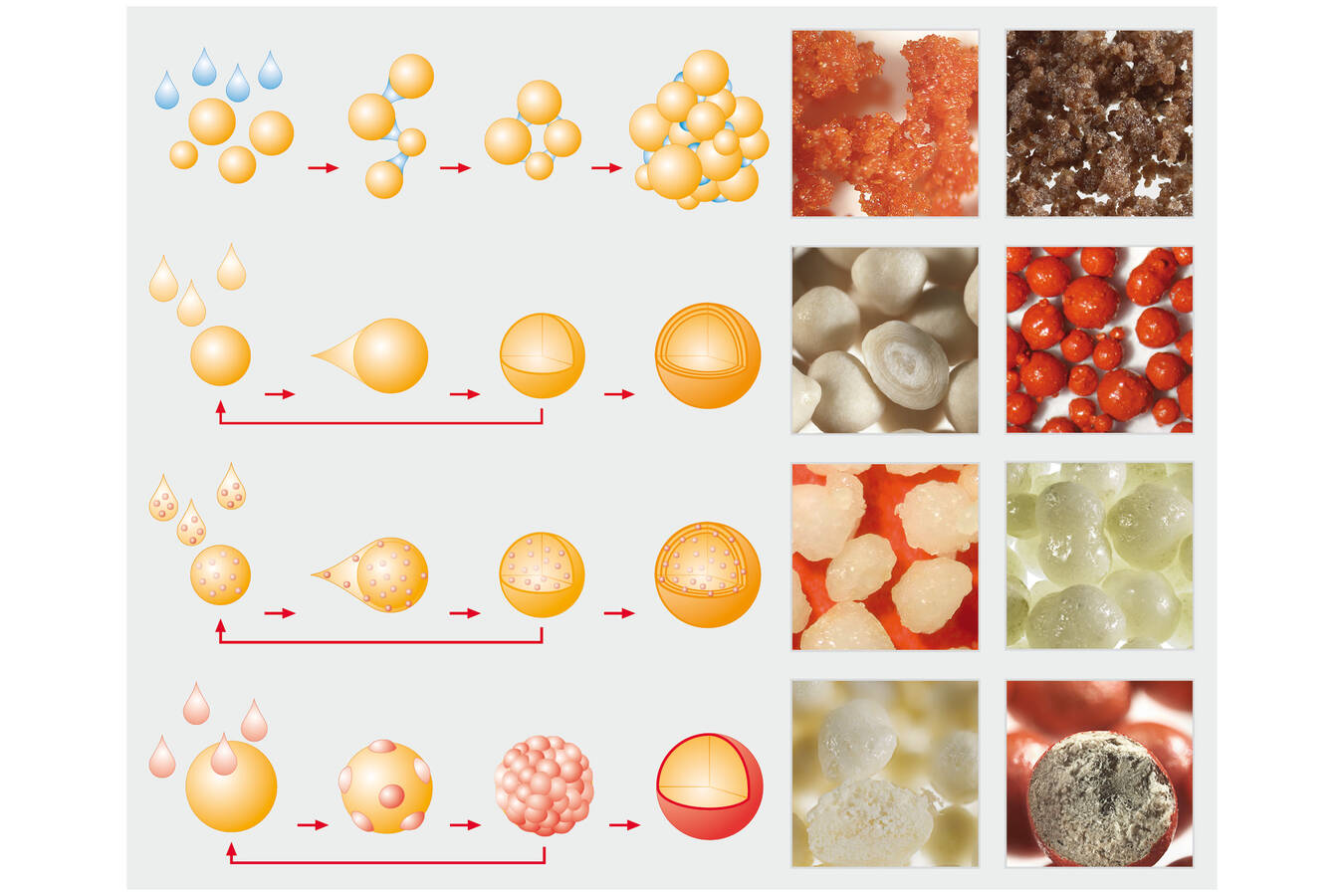

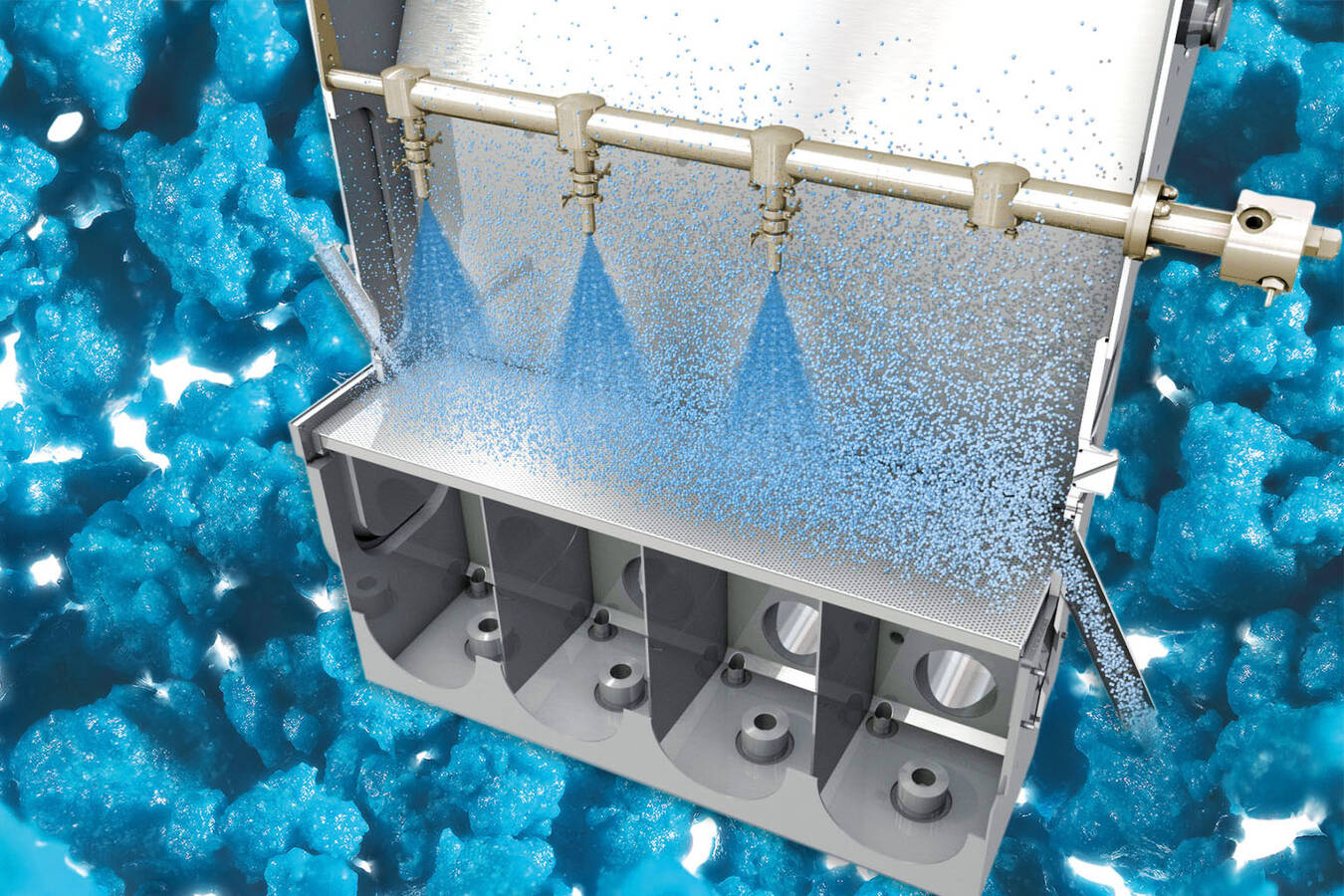

Sztuka: The dry Ronaflux® pigments have to be coated very homogenously and under strict cosmetic guidelines. First, the powder is fluidised by inert gas and heated up to the required reaction temperature. A thin carbon layer is then formed by decomposition of a carbon containing gas. After the carbon coating, the powder is cooled, sieved and packed under strict hygiene conditions.

EC: What process engineering know-how does Glatt have in this development?

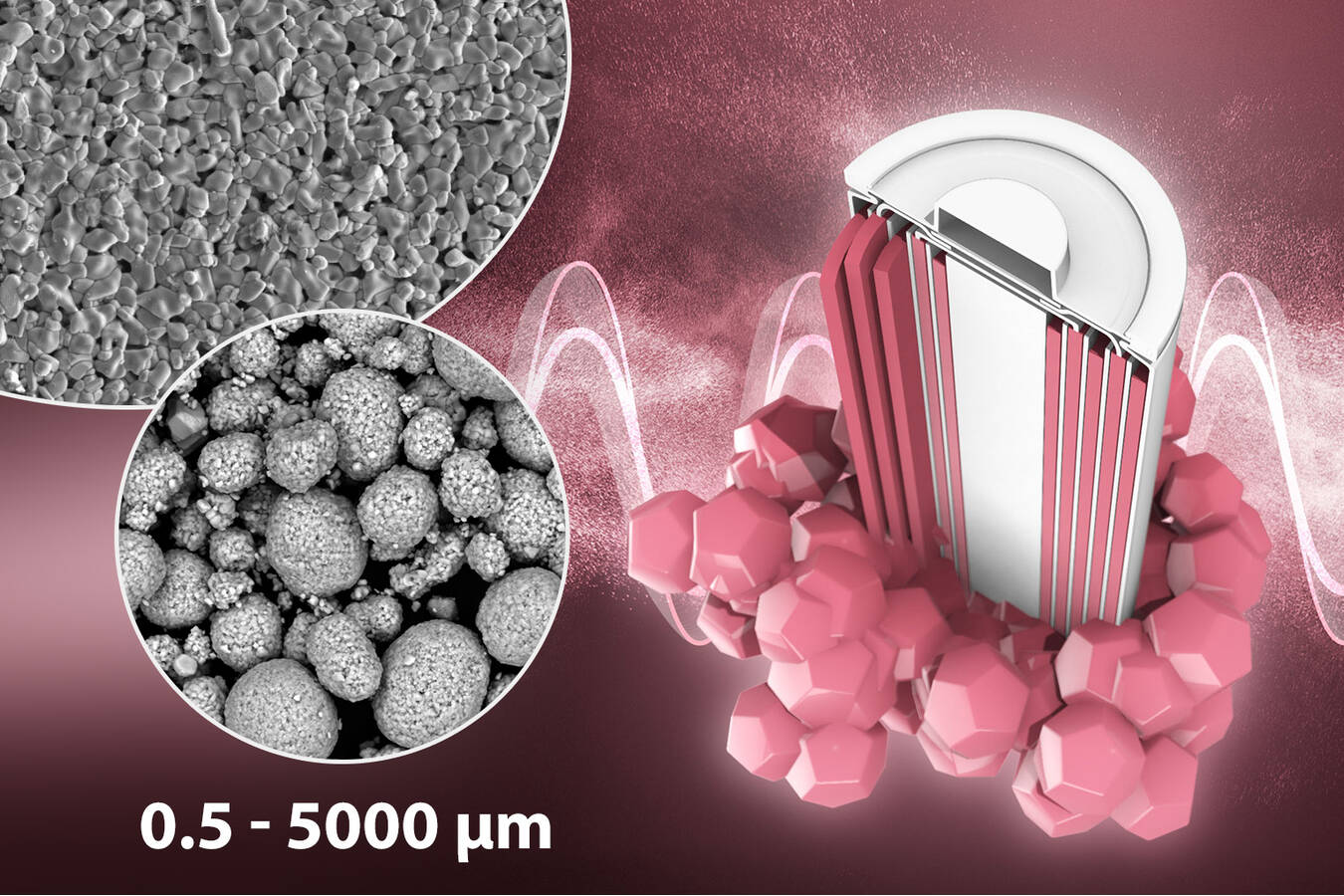

Teiwes: Our decades of experience in particle technology and solids process engineering — as well as fluid mechanics and liquid processing — form a good basis for new and future developments such as these. On the one hand, we’ve completed many projects based on classic fluidised bed or spouted bed technology and, on the other hand, our contract development work involving particle generation and functionalisation ensures that we continue to grow our knowledge base. When it comes to implementing fluidised bed, spouted bed or powder synthesis processes under special operating conditions, that’s when our process engineering know-how comes to the fore. The production of Ronaflux® pigments is a good example, because it needs a special gas atmosphere at high temperatures and special fluidisation assistance to ensure a precise and even particle coating for the very cohesive raw material powders.

EC: What is behind the Dryflux technology?

Sztuka: The Dryflux technology is both sophisticated and simple. Ultrathin and highly stable carbon layers are homogenously precipitated in a gas phase onto the pigments, which is a major precondition for spectacular shine effects. The carbon layers intensify the effect of the colour pigments, thus making brilliant shades of blue and green possible without the addition of chrome oxides, Prussian Blue or other colorants. This enables manufacturers of eye makeup and lipsticks to meet strict regulatory requirements while offering brilliant, metallic blue and green shades that do not contain any metal-based pigments.

EC: What is special about the Dryflux reactor developed by GIT?

Teiwes: Dryflux works on the basis of chemical vapour deposition (CVD). This is already used in various industries, but a CVD process of this scale and for cohesive cosmetic pigments, which are used directly on human skin, is completely new. Currently, there is no other facility of its kind. What’s also impressive about this plant is the special kind of fluidisation assistance and that it was developed, constructed, built and put into operation in a relatively short period of time.

EC: The long-standing cooperation with Merck was certainly very helpful here, wasn’t it?

Teiwes: The basic technology was already available but, without constant and open communication throughout the entire project, it would not have been possible. It’s vital that everyone buys in to fulfilling the task, that there is a common understanding and mutual respect. If we’re not all working towards the same endpoint, then the process development, scale-up and commercialisation of such a project won’t succeed. But, this is something that doesn’t just apply to our relationship with Merck. A trust-based partnership is an essential part of every customer project. Another factor to consider is that without our pharmaceutical engineering expertise and our pedigree of planning and completing cleanroom projects for GMP production — also in the cosmetics sector — this development would not have been possible.

Our Interview Partners

- Dipl.-Ing. Arne Teiwes; With a special interest in fluidisation technology and particle formulation processes, Dipl.-Ing. Arne Teiwes specialises in solids process engineering and particle technology. He worked as a scientific research engineer at Hamburg University of Technology and as project engineer at Glatt Ingenieurtechnik (Weimar, Germany). Now focusing on process development and high temperature solids processing, he is currently focusing on New Technologies and Technology Development at Glatt.

- Dr Katarzyna Sztuka; Dr Katarzyna Sztuka currently serves as the Head of EMEA Regional Marketing for Merck Electronics, Surface Solutions with experience and interest in cosmetics, automotive and industrial decorative & functional materials. With a Ph.D. in Chemistry (Biotechnology specialization) and an M.Sc. in Chemical Engineering, she possesses a strong foundation in both academia and practical application.

Katarzyna’s career began with a role in research and development at J.S. Hamilton Poland Ltd. Sp. z o.o., where she played a hands-on role in innovation. In 2010, she transitioned to Merck Poland as an Area Sales Manager, and in 2016 she elevated her career as Country Manager for Poland, responsible for Automotive, Cosmetics, and Industrials business sectors..

originally published in the magazine Euro Cosmetics, issue 9-10/2023, Inter-Euro Medien GmbH