Glatt is specialized in intelligent particle design for the generation and functionalization of powders and granulates with defined, adjustable properties.

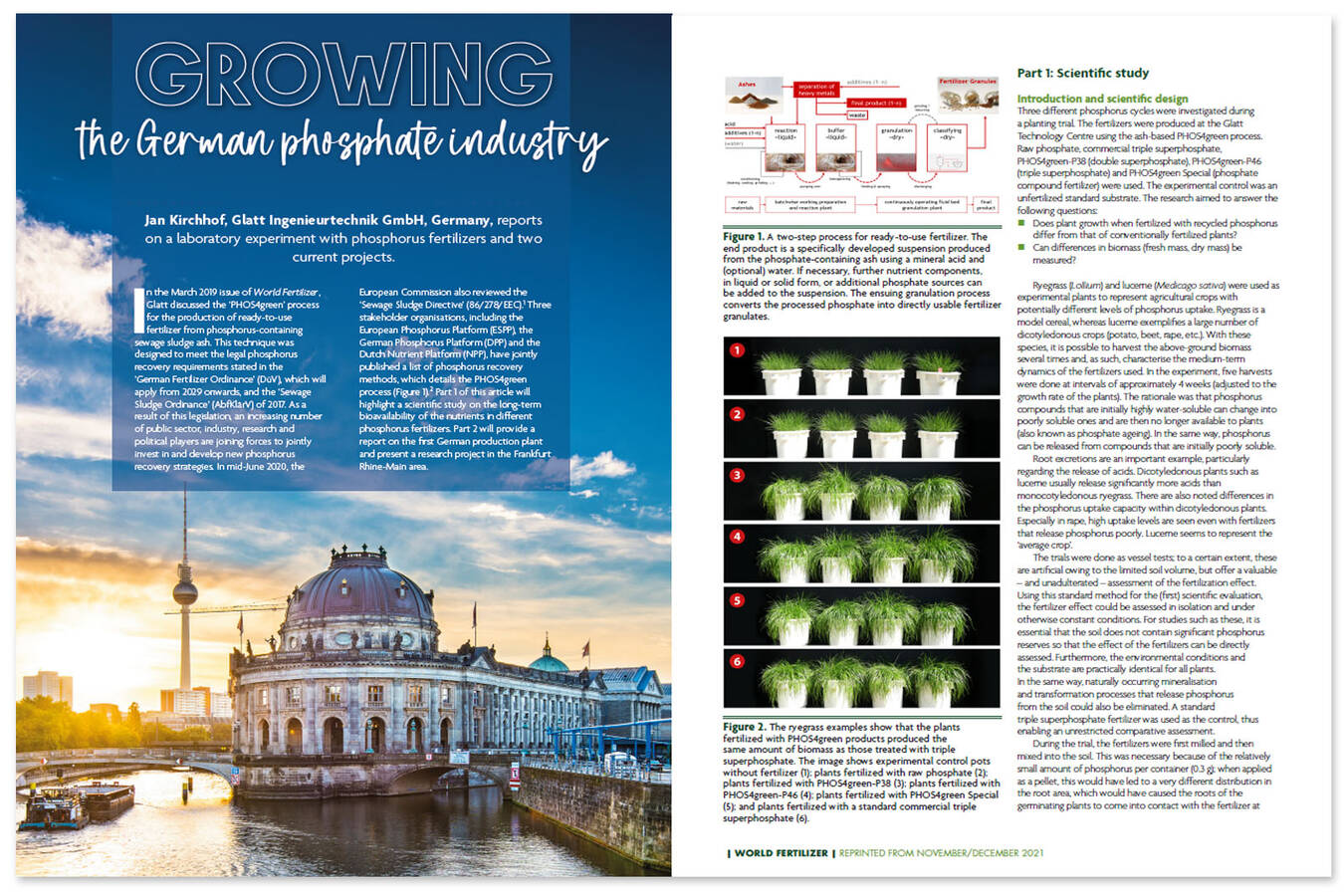

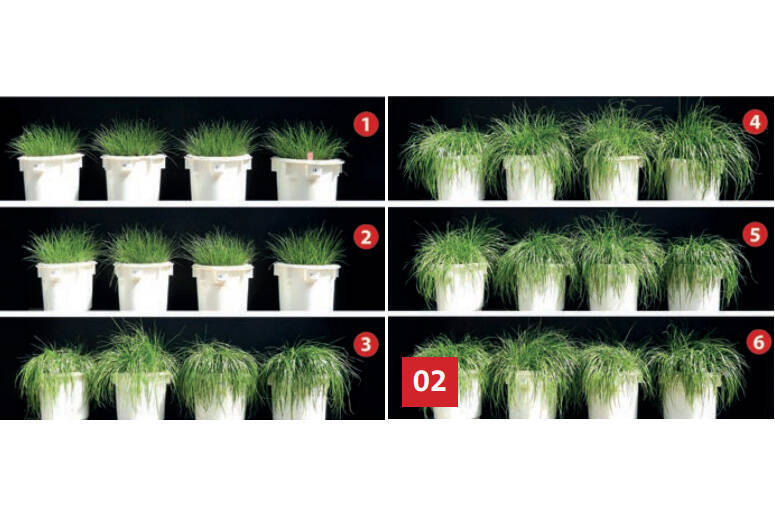

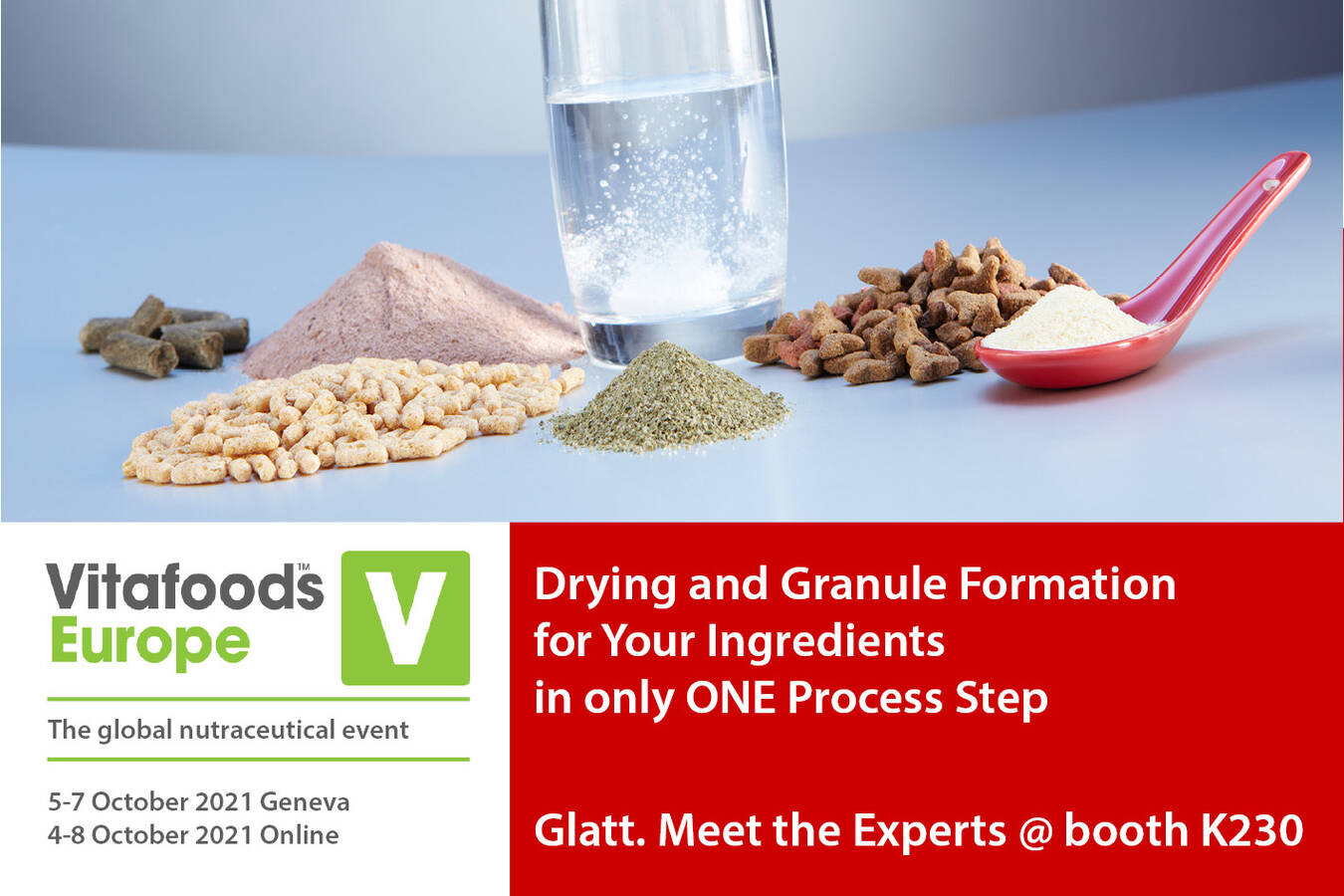

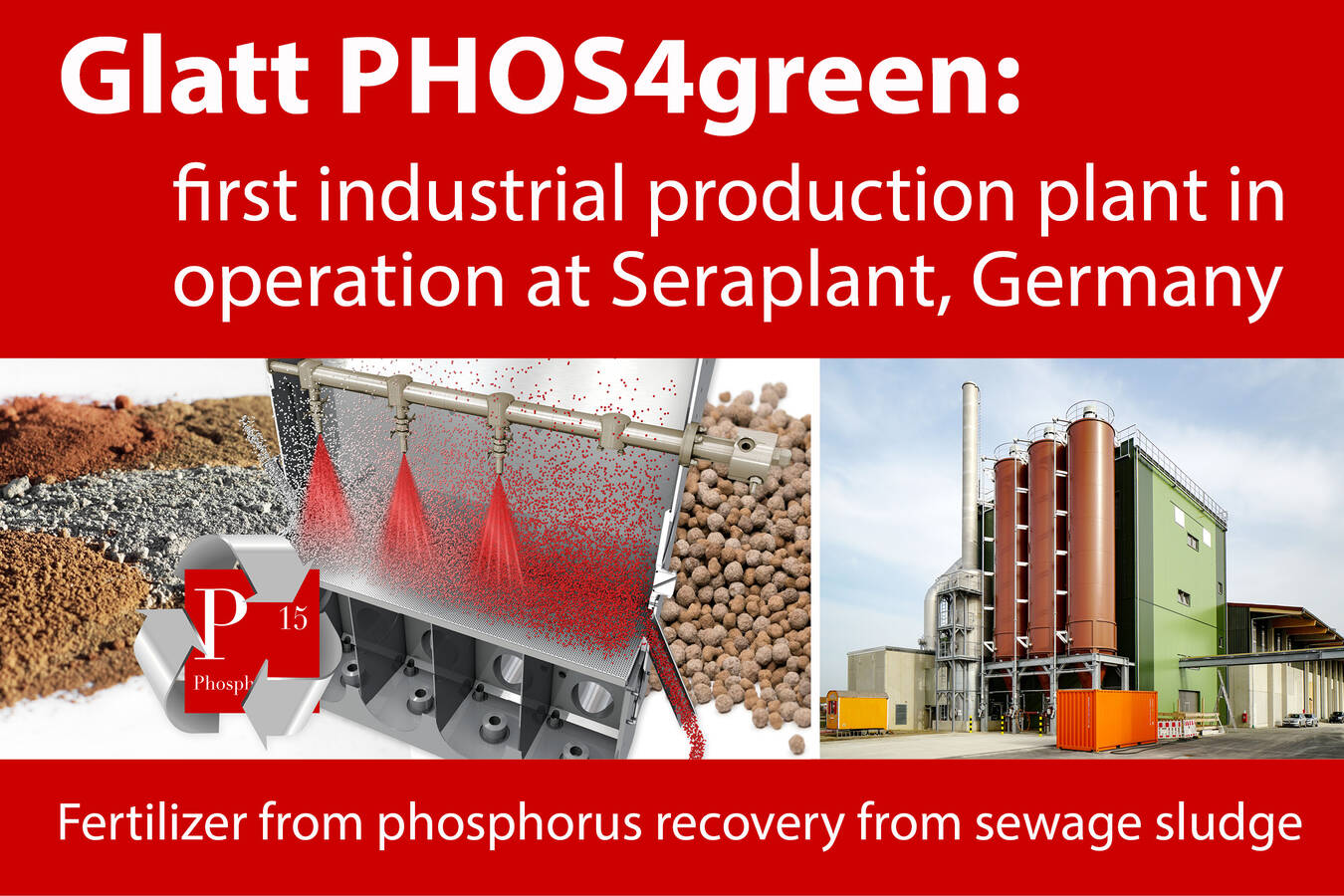

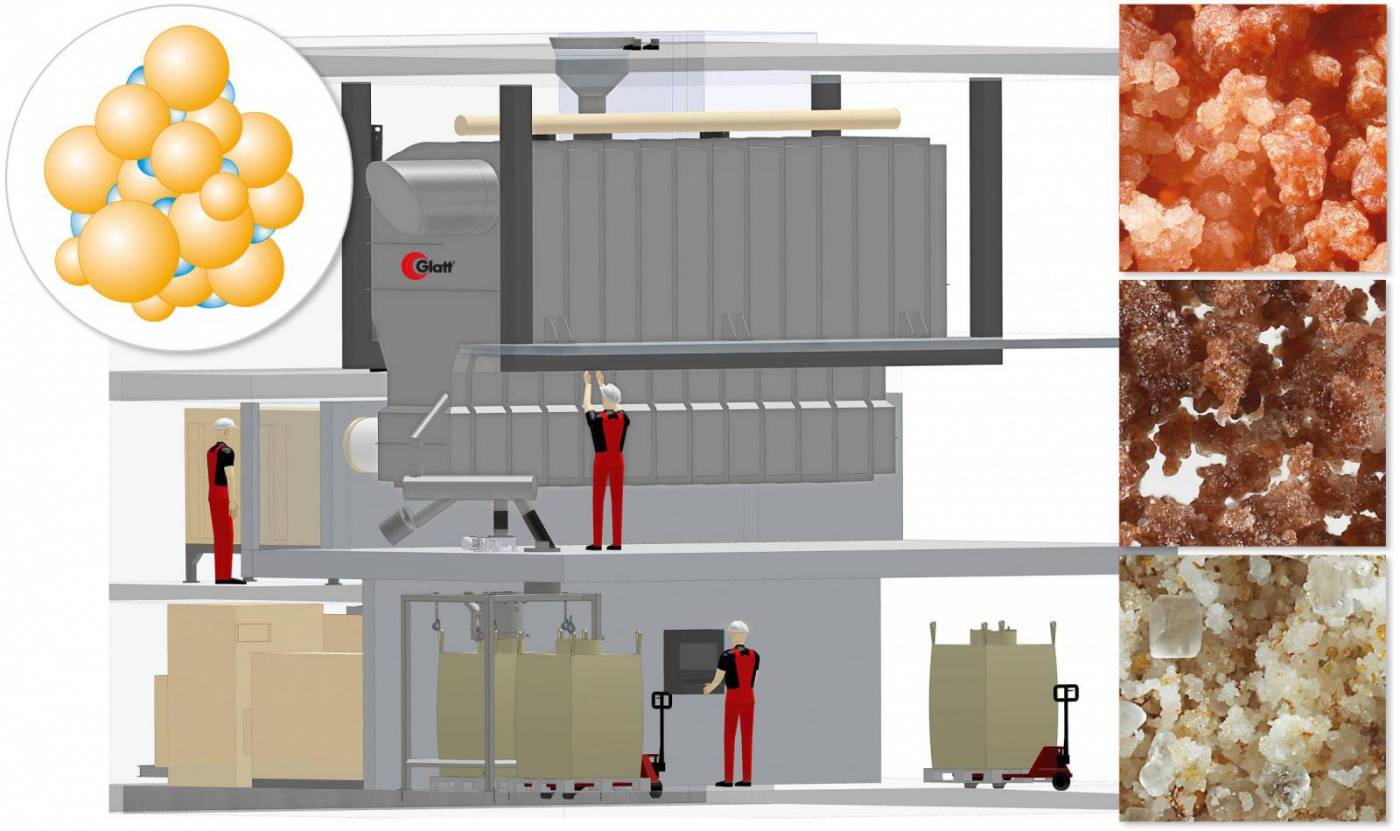

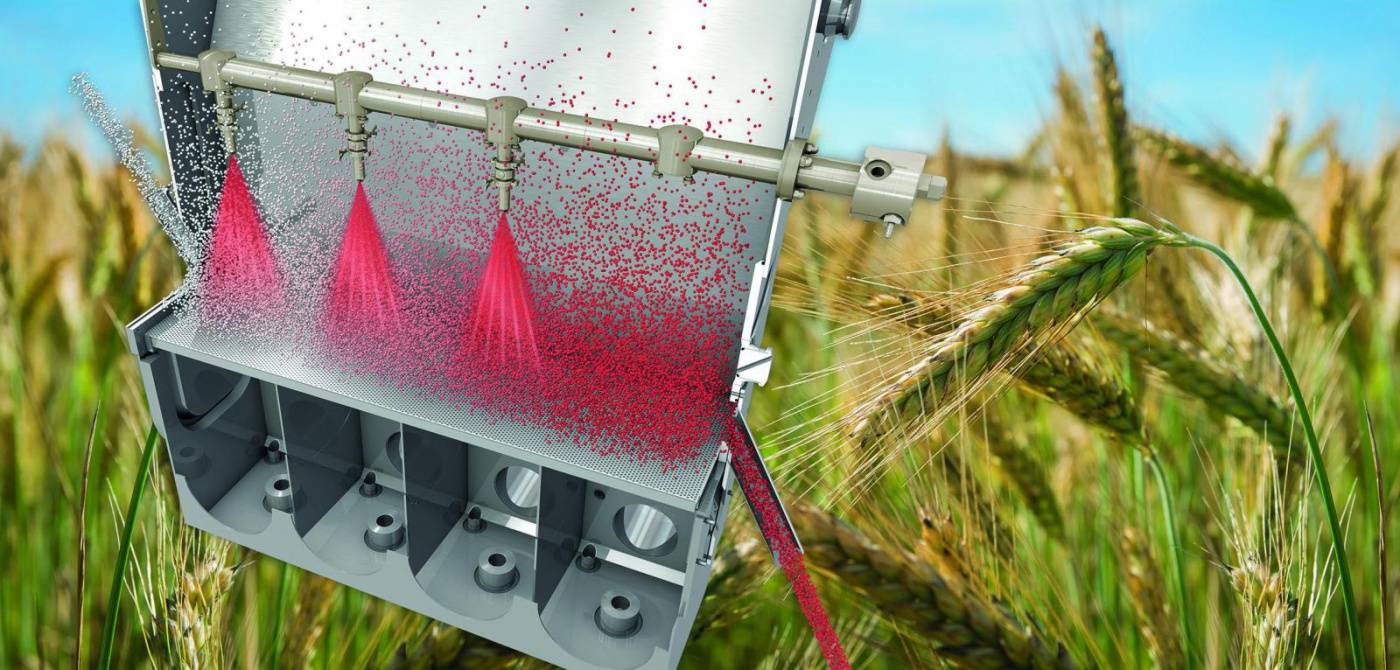

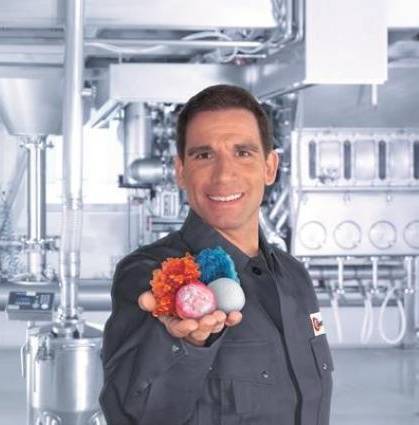

The focus is on particles and powders for pigments, catalytic, ceramic or battery materials as well as for granules and pellets as additives for e.g. industrial salts, detergents and cleaning agents, fertilizers, pesticides, food, feed, dietary supplements and pharmaceuticals.

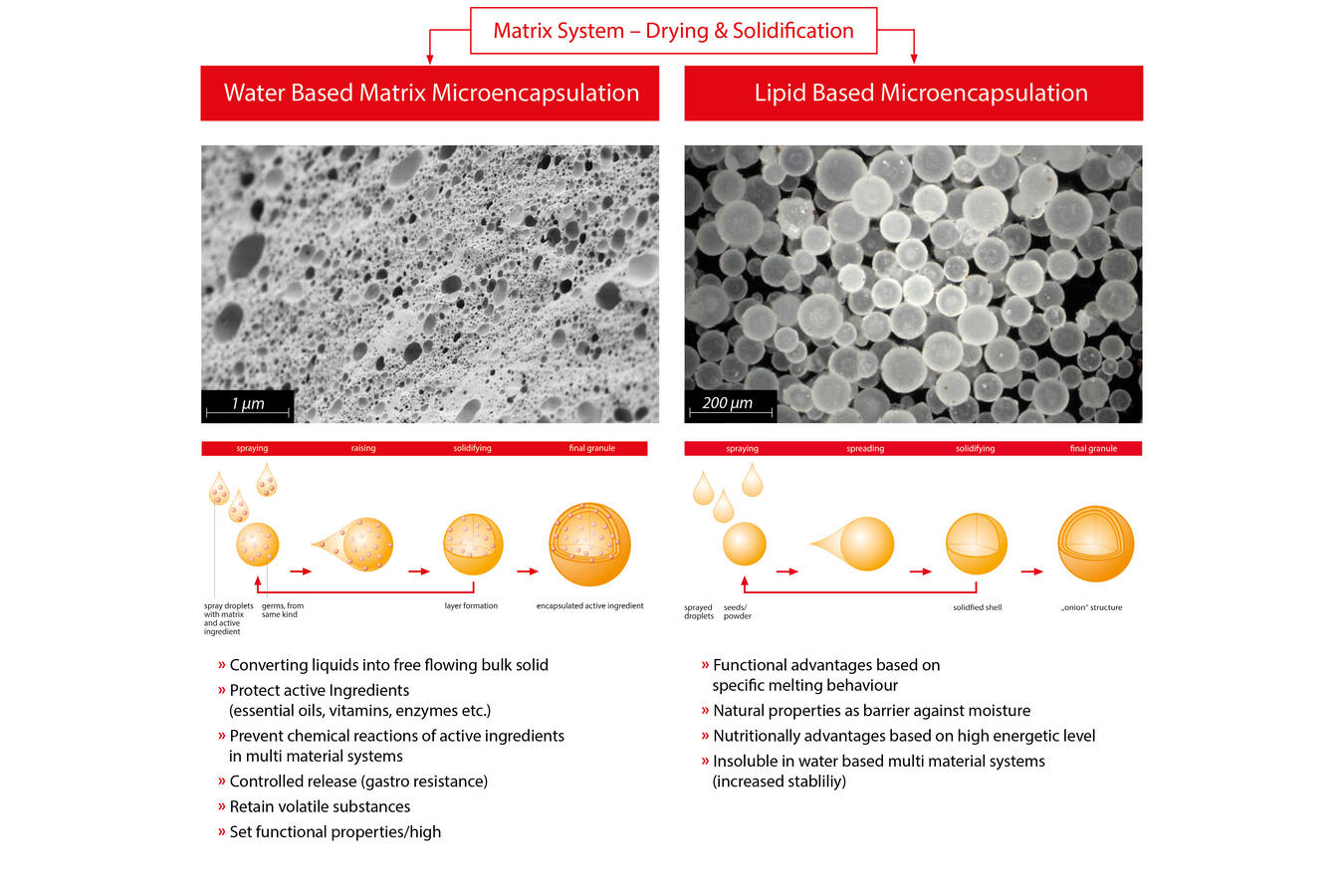

Encapsulation of flavors, enzymes, vitamins, microorganisms, probiotics or fatty acids (PUFA) is just as possible as encapsulation of essential oils and other active, sensitive substances to be protected.

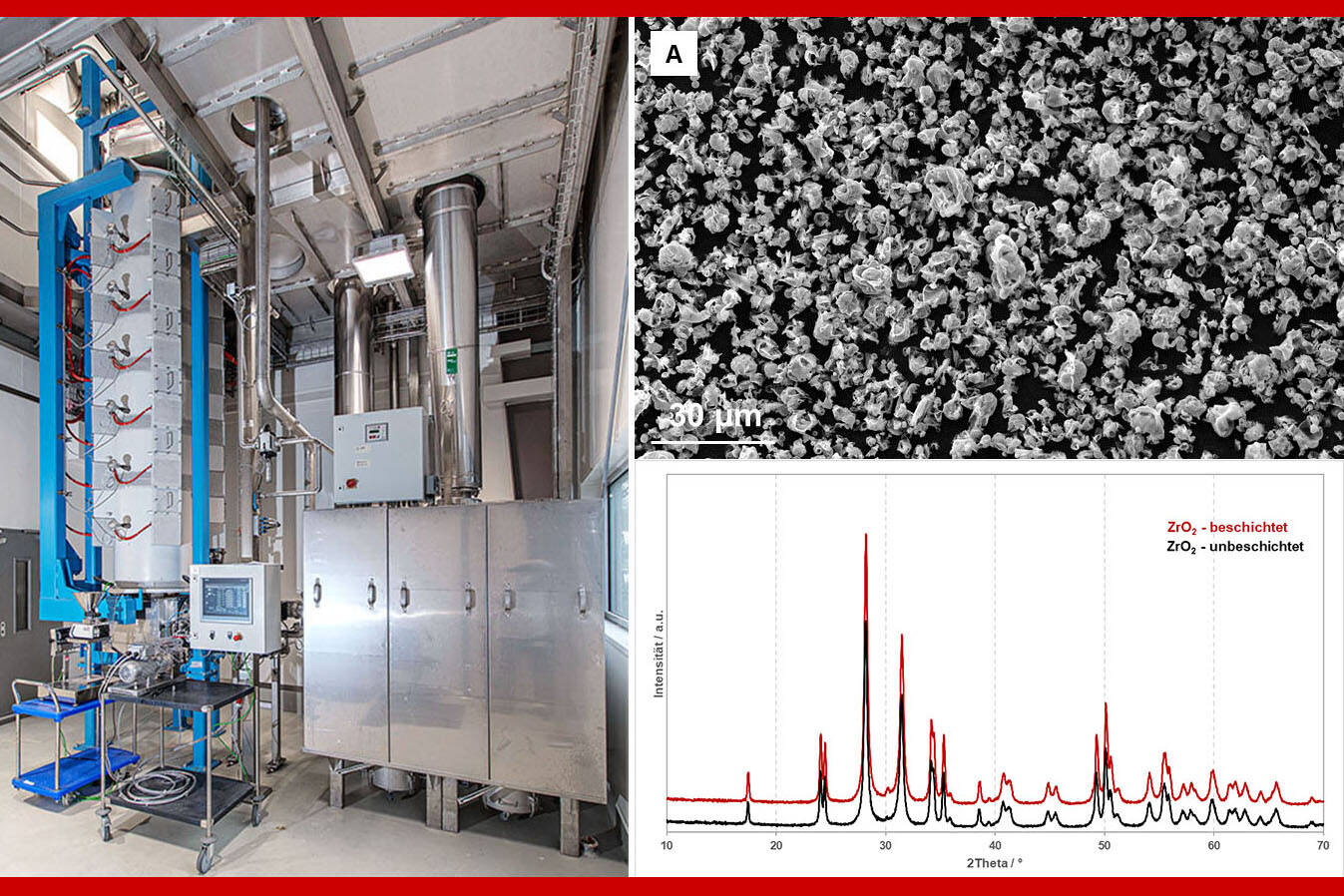

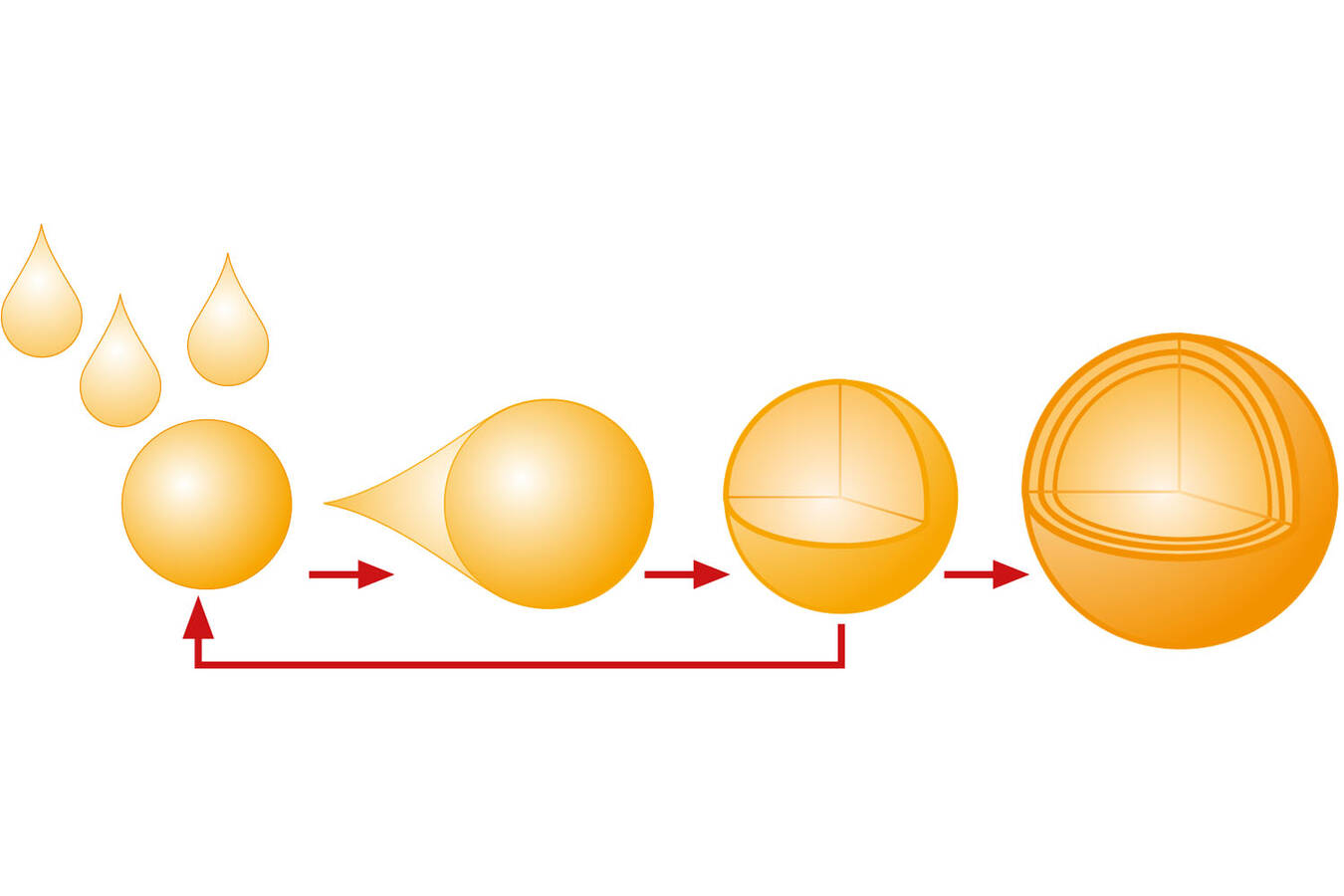

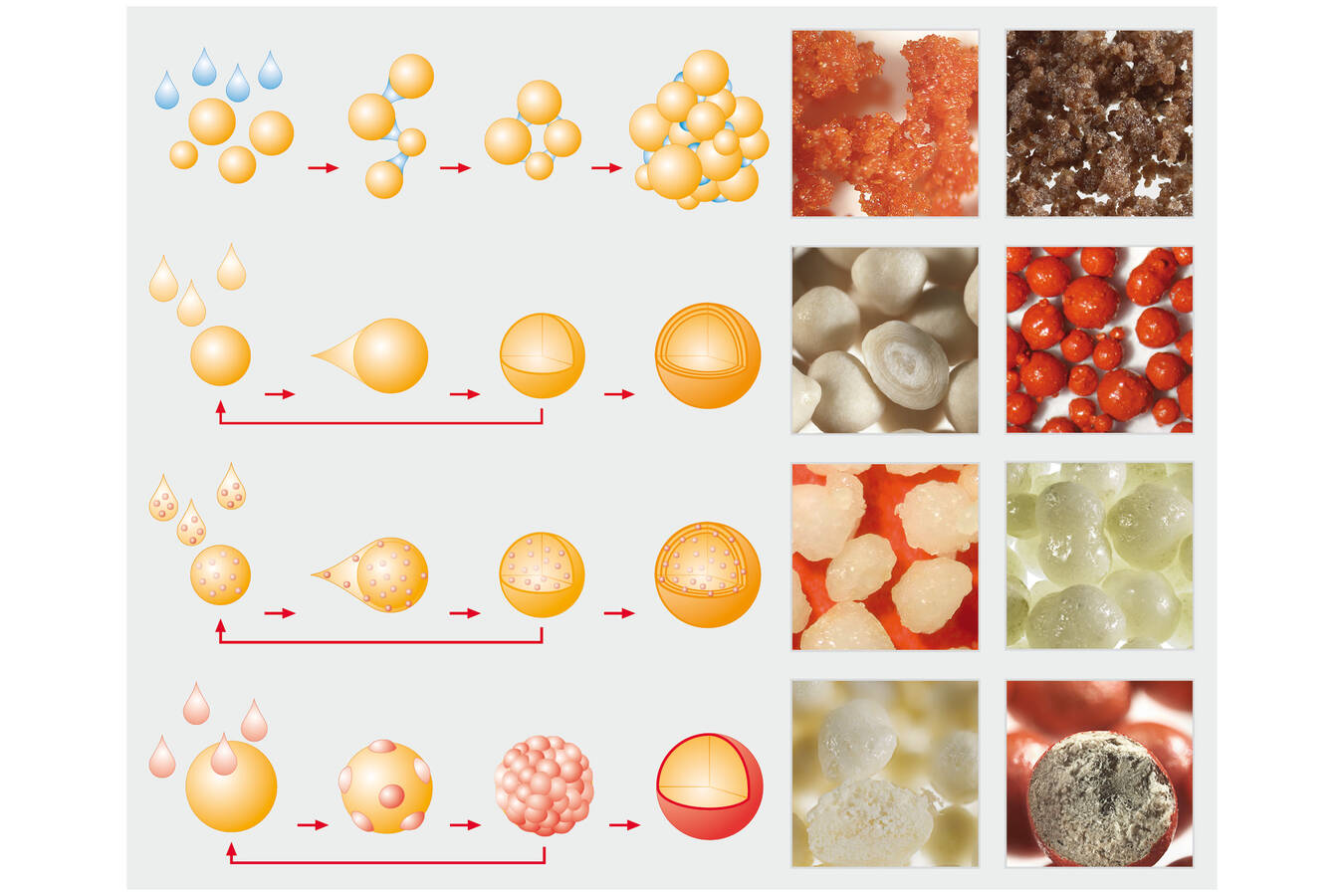

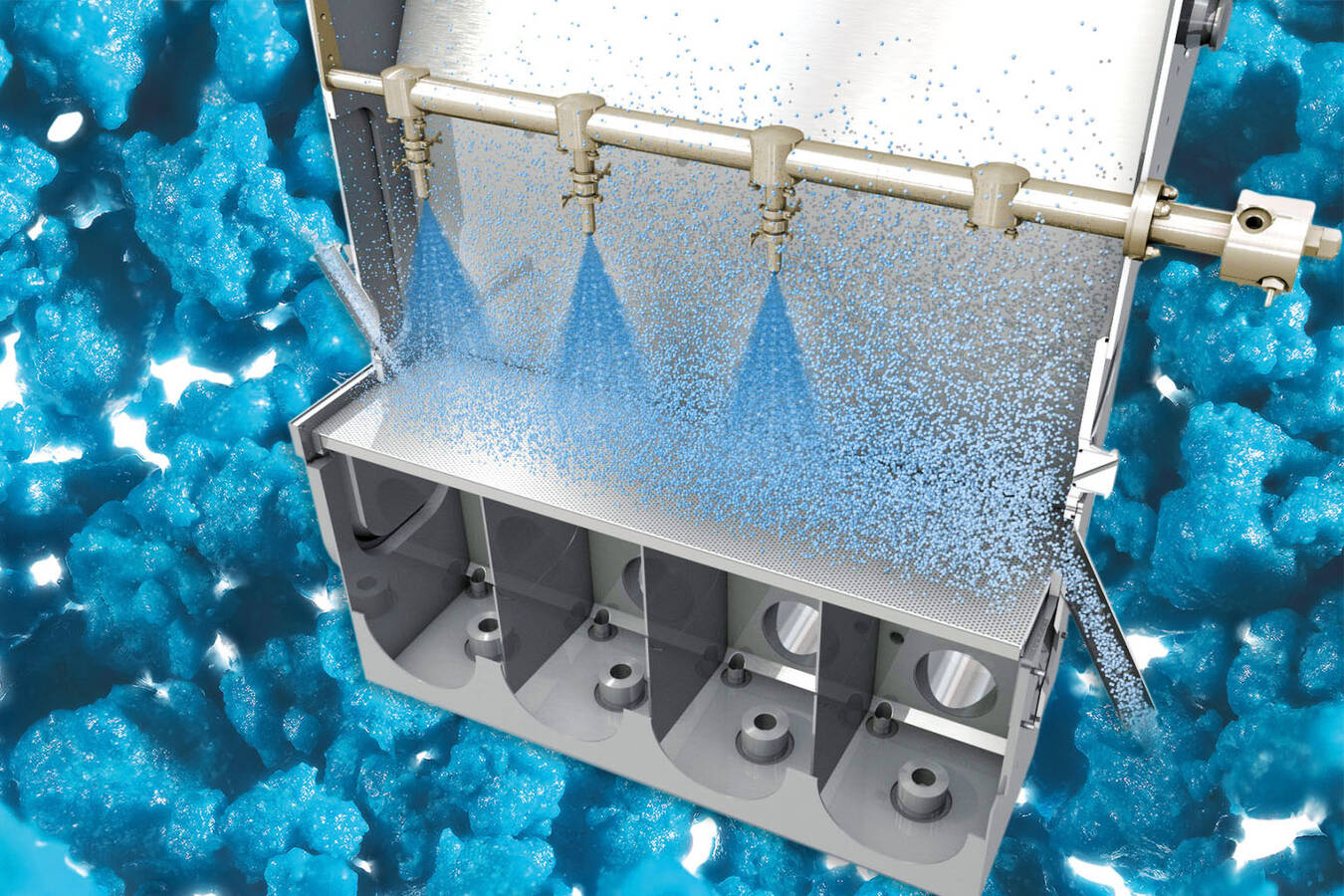

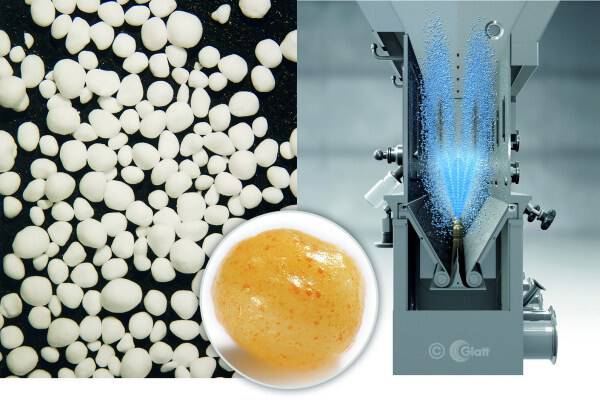

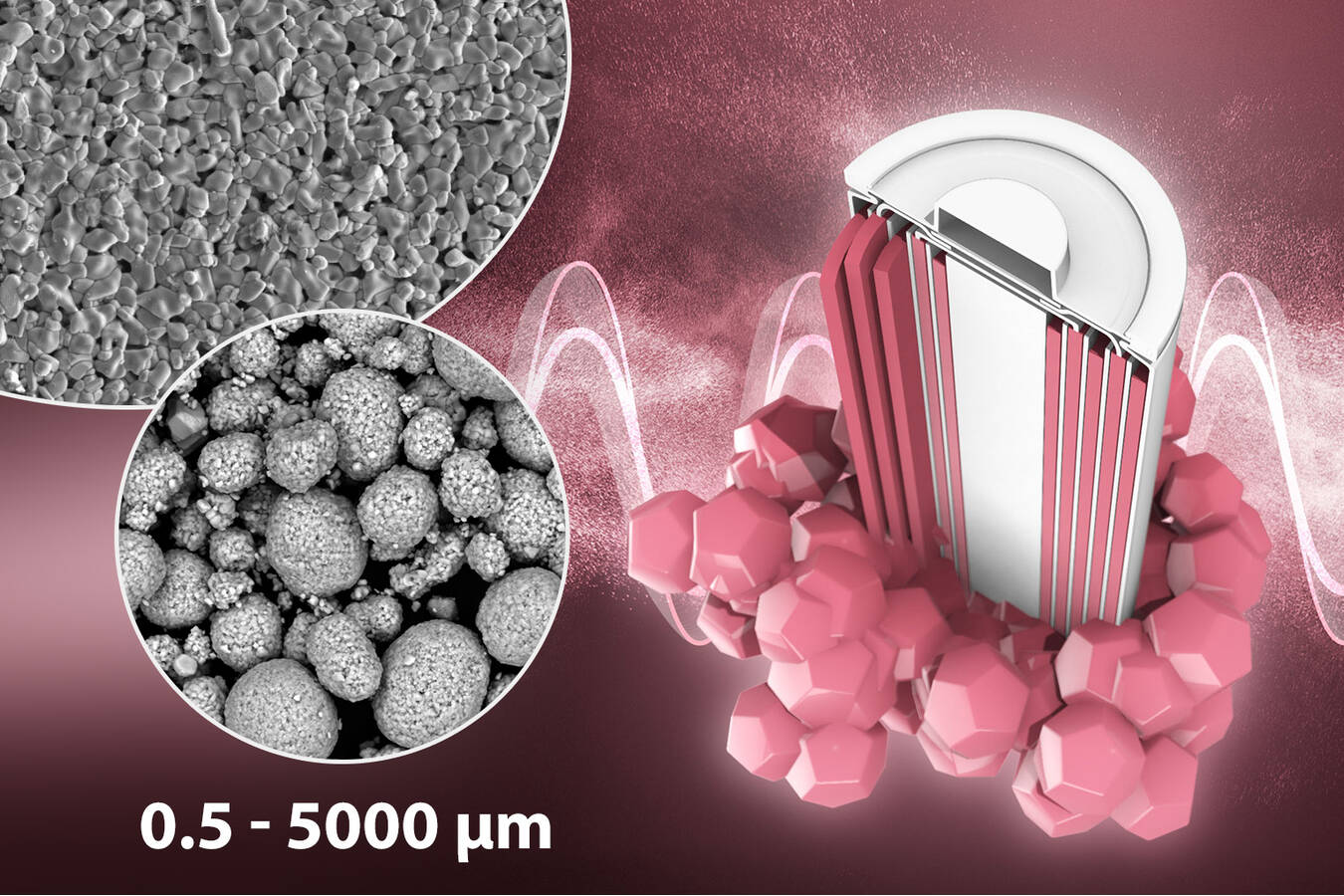

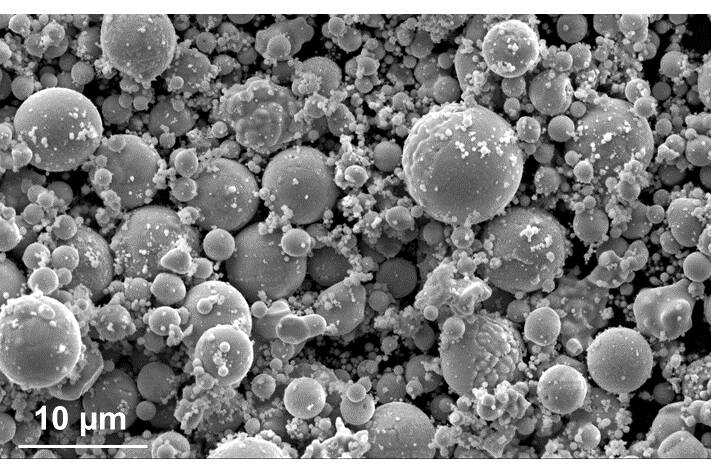

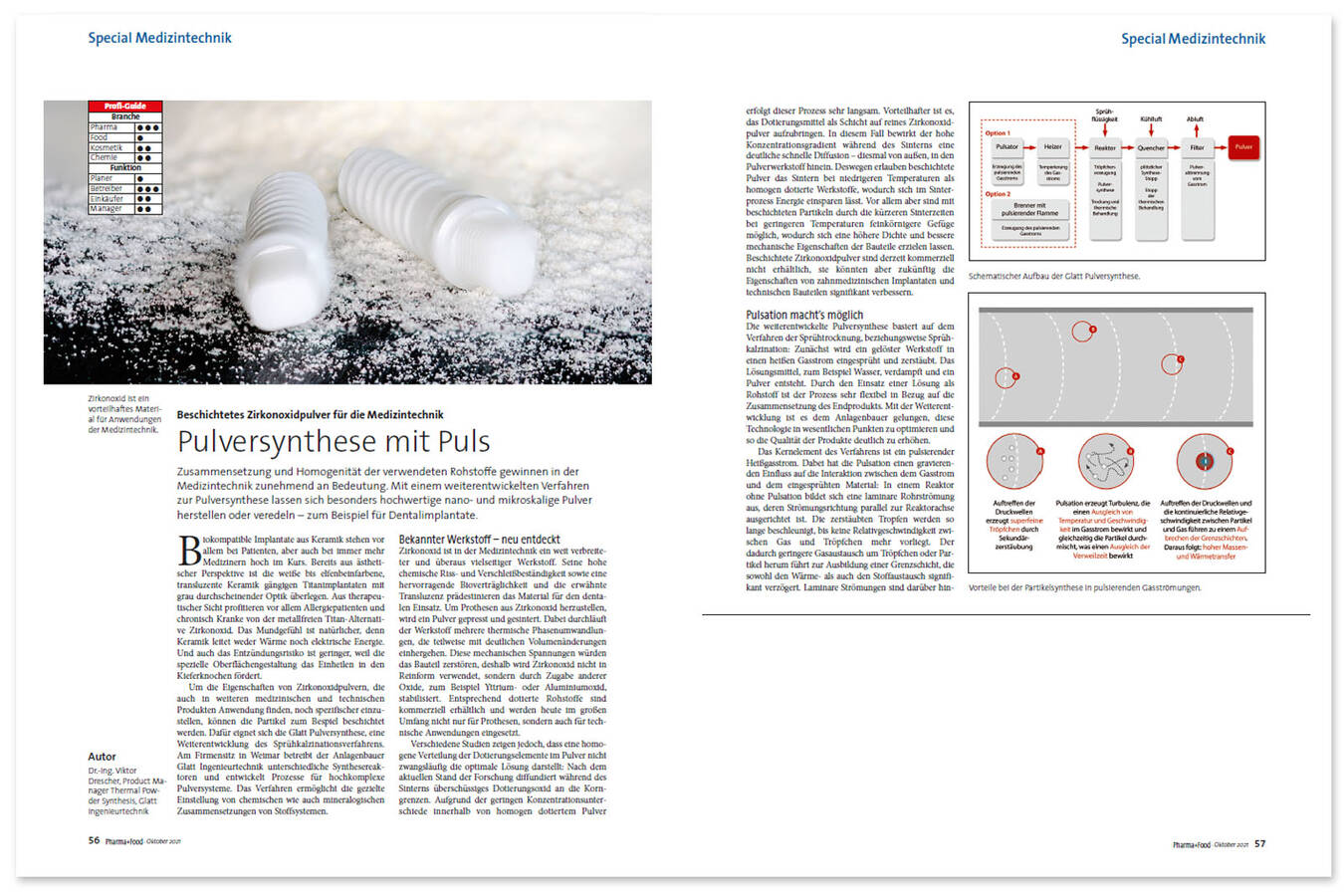

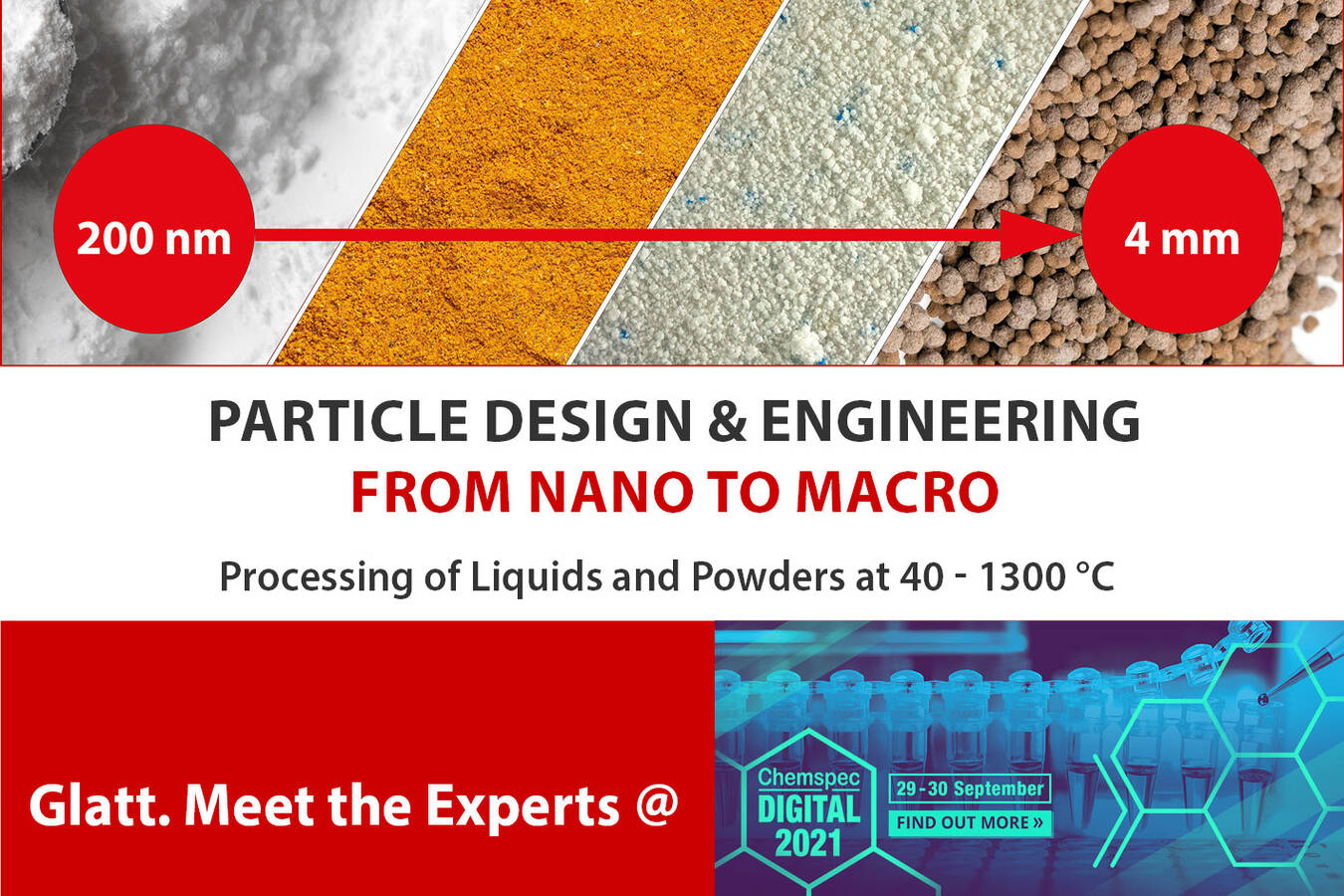

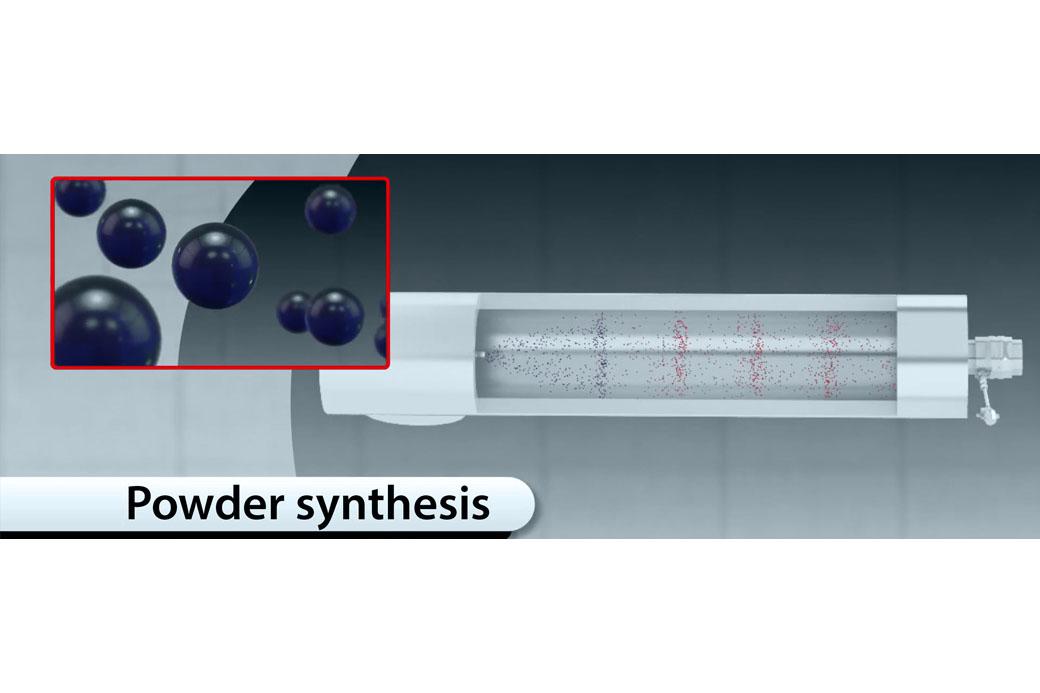

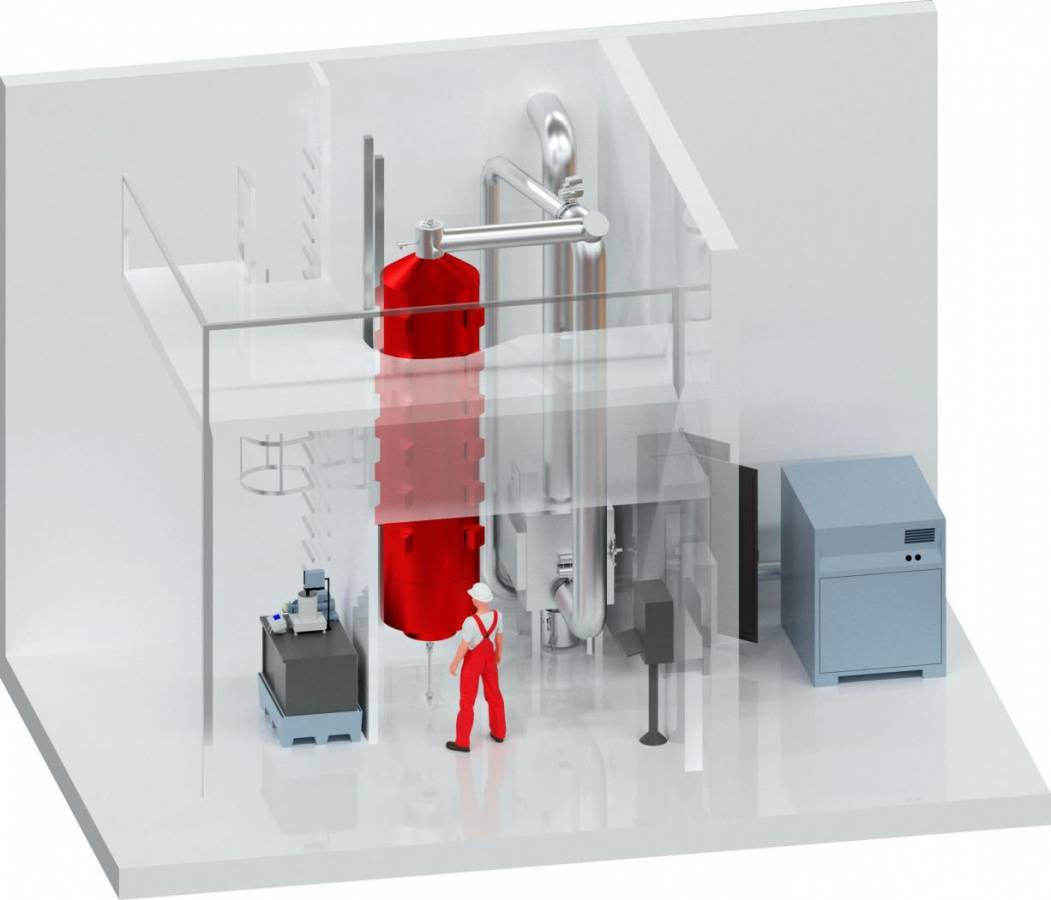

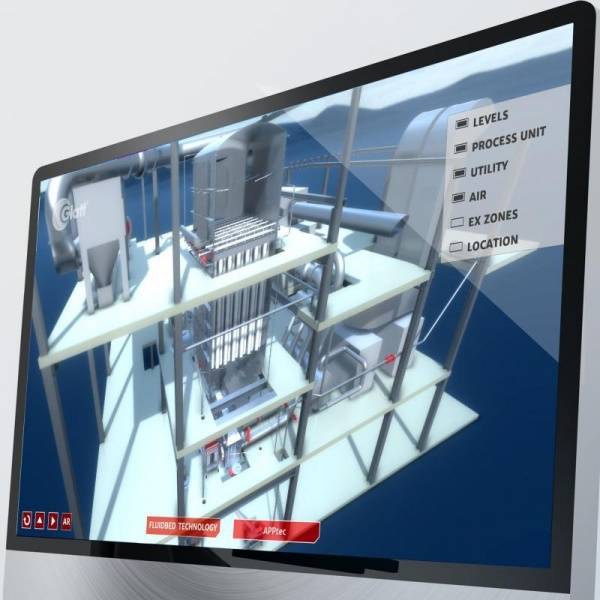

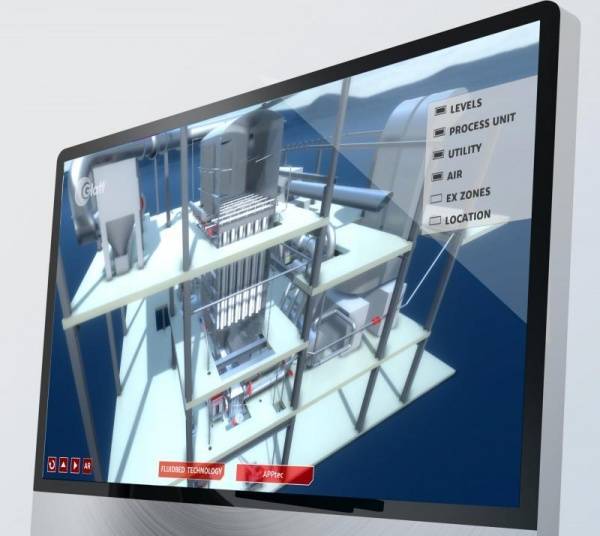

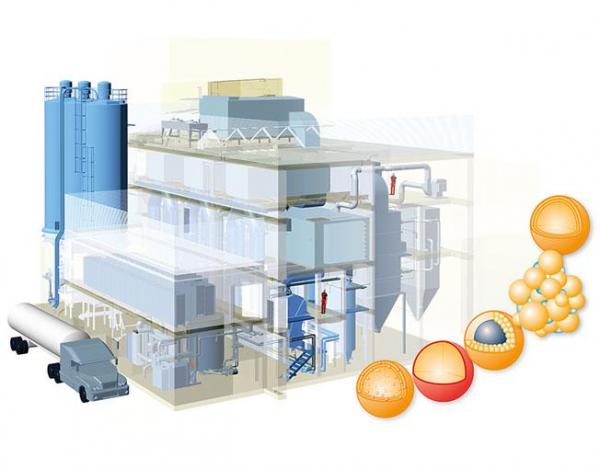

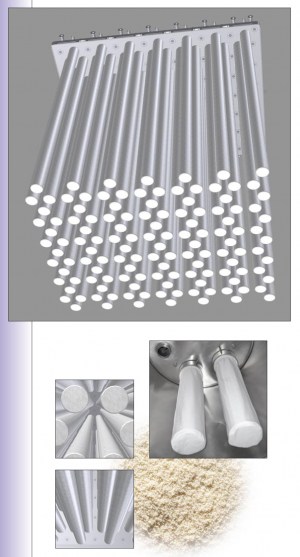

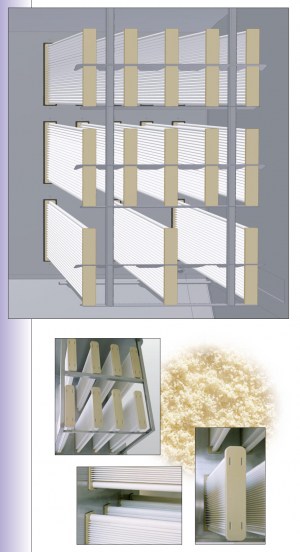

With Glatt APPtec®, a unique technology for spray calcination, it is possible to generate, coat and then calcine particles in a pulsing hot gas stream in a single process step. As a pioneer in fluid bed and spouted bed technologies, Glatt masters these important processes for the formulation and optimization of particle properties through defined spray agglomeration, spray granulation, spray coating or (micro)encapsulation as well as through combinations of these processes. Also in the high temperature range. Glatt supports the product idea from the early phase of product formulation through process development to scale-up to production scale.

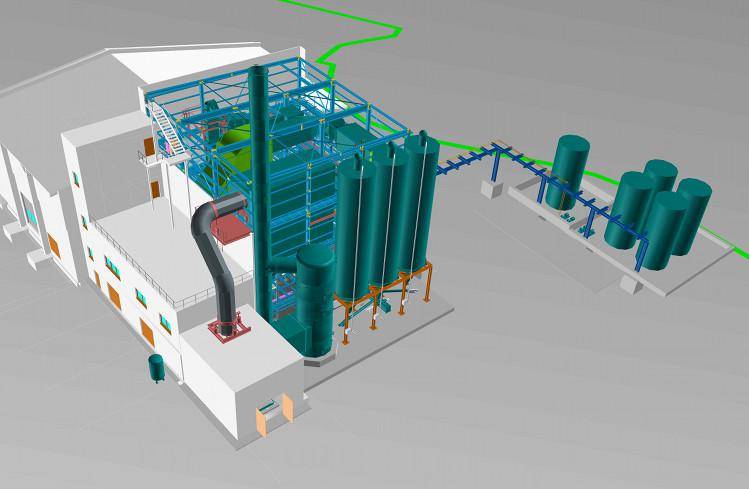

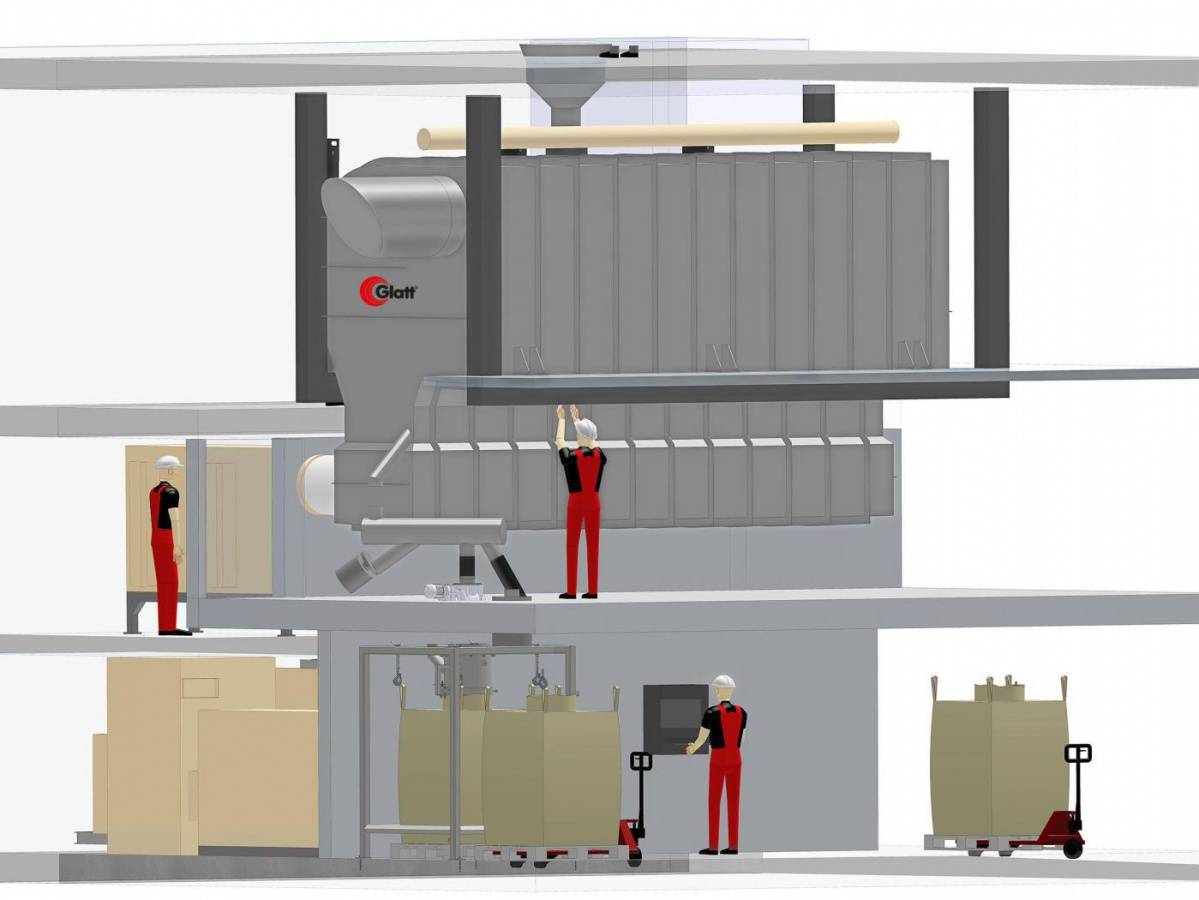

Under the leadership of the Glatt Process & Plant Engineering teams, customized production plants for nutrition, fine chemicals, pharmaceuticals, and biotech applications are successfully planned and commissioned. Worldwide.

Whether based on powder synthesis, fluid bed or spouted bed technology, Glatt also offers certified contract manufacturing for customers without their own production capacities.

Products, services

Fluidized bed technology - agglomeration, granulation, spray granulation, coating, drying, encapsulation, microencapsulation, micro-encapsulation, high temperature

Powder Synthesis - spray calcination, calcination, spray pyrolysis, core-shell, PSD particles, nanoparticles

Contract manufacturing - powder, pellets, granules, granulates, ingredients, food, detergents, fertilizers, chemistry, cosmetics, feed, nutraceuticals, additives

Spouted bed technology - granulation, spray granulation, coating, drying, encapsulation, microencapsulation, micro-encapsulation