Size reduction and particle size analysis

in the paint and coatings industry FRITSCH is an internationally respected manufacturer of laboratory mills for grinding and mixing of different materials and mixtures and for particle size analyses according to laser diffraction, dynamic light scattering, dynamic image analysis and sieving.

Here a short view of the FRITSCH instrument ranges:

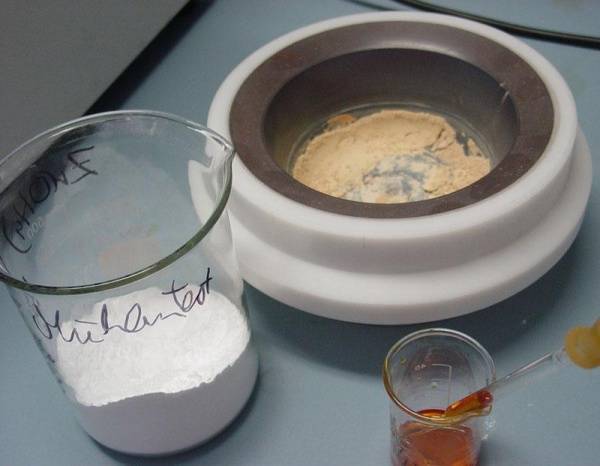

- Mills for crushing, micro-milling, mixing, homogenising of hard-brittle, fibrous, elastic and or soft materials dry or in suspension

- Instruments for particle size determination by means of static and dynamic light scattering, dynamic image analysis and sieving

- Laboratory Instruments for representative dividing of dry and wet samples, controlled sample feeding, ultrasonic cleaning

Laboratories worldwide count on our quality and experience – for the fast industrial application as well as for the especially accurate research technology applications in the industry- and research laboratories.

In the paint and coatings industry, the Variable Speed