The company VTTI Bio-Energy will ferment 300,000 tonnes of manure and 25,000 tonnes of organic residues annually at the De Spinder business park near Tilburg and process the digestate into manure pellets. Annually, 23 million cubic metres of biogas will be generated. Of this, about 7 million cubic metres will be upgraded into green gas that will go to the gas grid.

Manure pellets

Much of the biogas is used to dry the thick fraction of digestate and concentrate from the thin fraction and process it into pellets. Annually, the company will manufacture 40,000 tonnes of manure pellets.

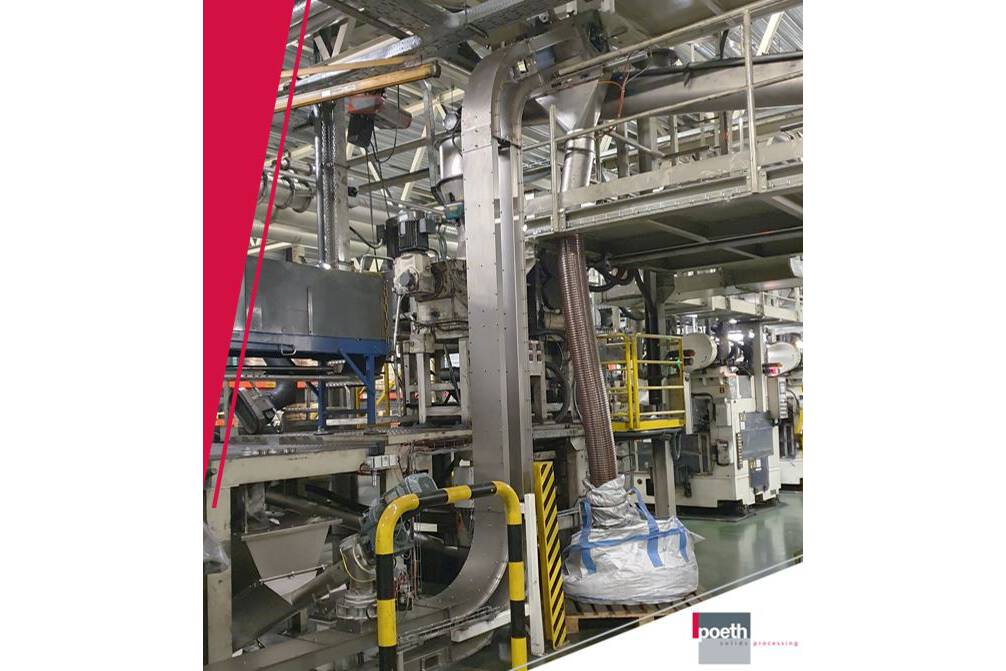

The hall consists of three parts and has an area of 2,000 m² and will be 15 metres high. In the middle part, the digestate will be separated and the thin fraction purified into dischargeable water. A second part is used for drying the digestate and processing it into granules, which also houses Poeth’s scope.

Poeth Solids Processing’s scope includes :

- Three pellet presses

- Post Conditioner

- Cooler

- Z-Conveyors

- Conveyor screws

- Container loading

- Big-Bag filling system

- Pneumatic conveying

- Cyclone Filter / Central suction

- Silos

- Steel construction / Platforms

- Steering / Cabling / Scada