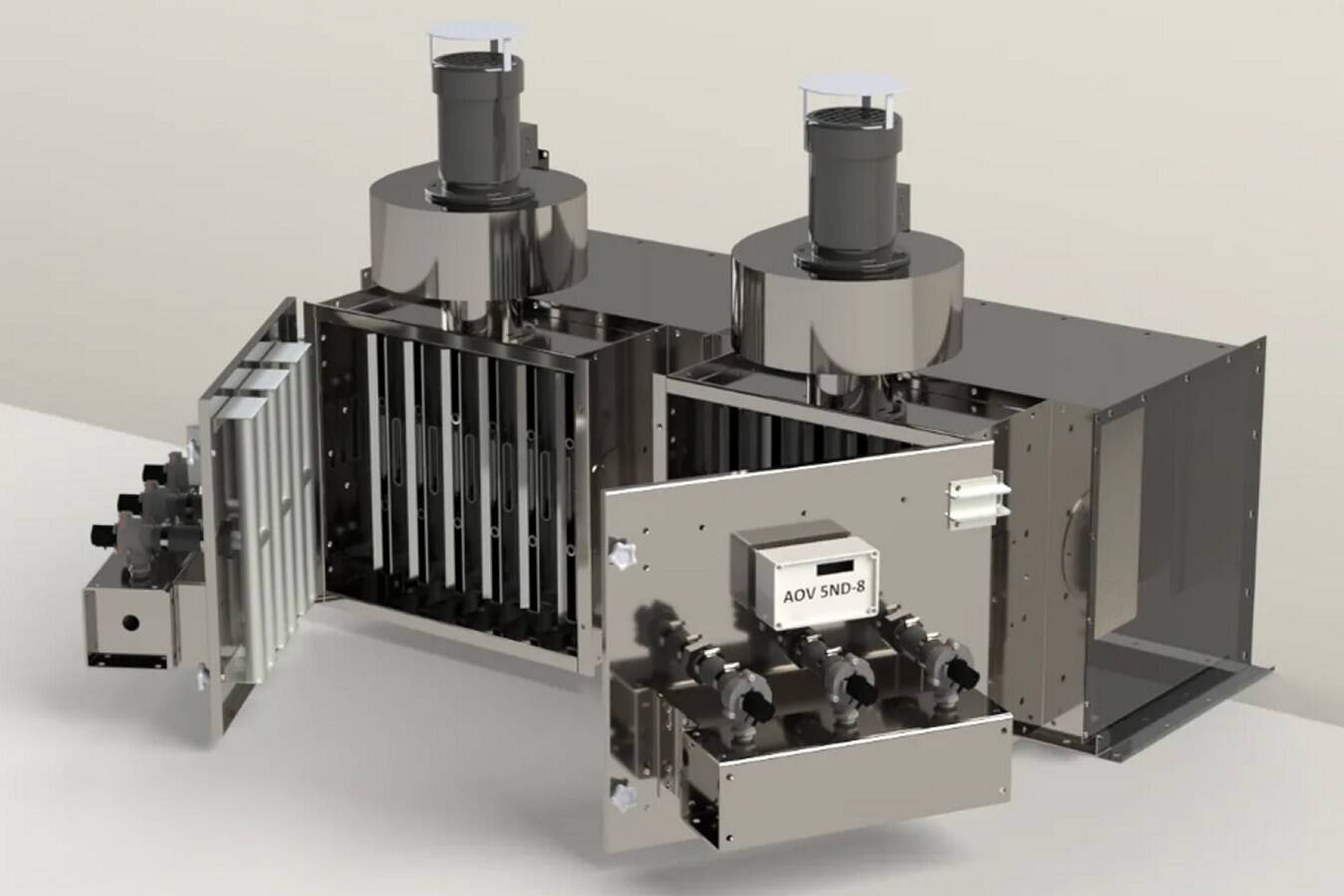

Mixer functions to increase mixing efficiency and profitability

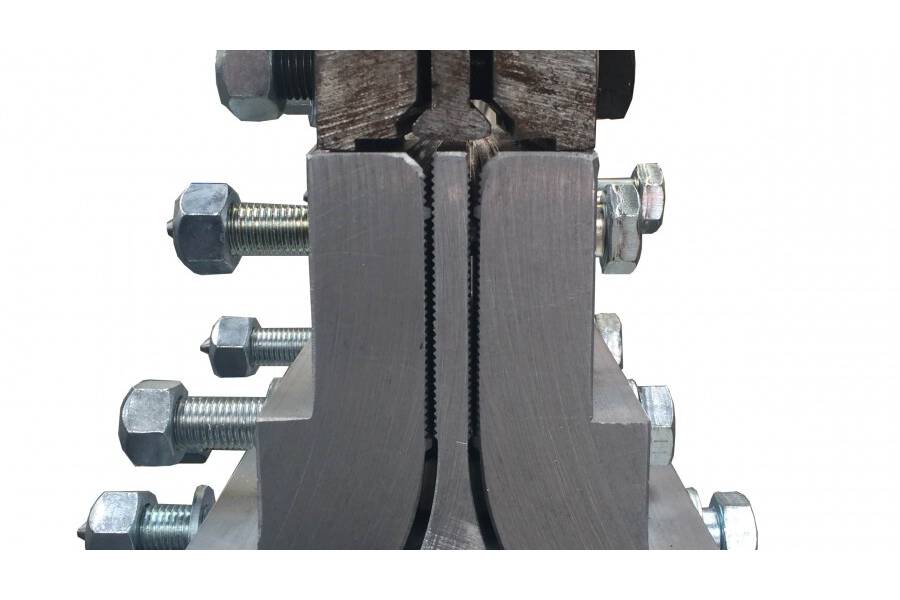

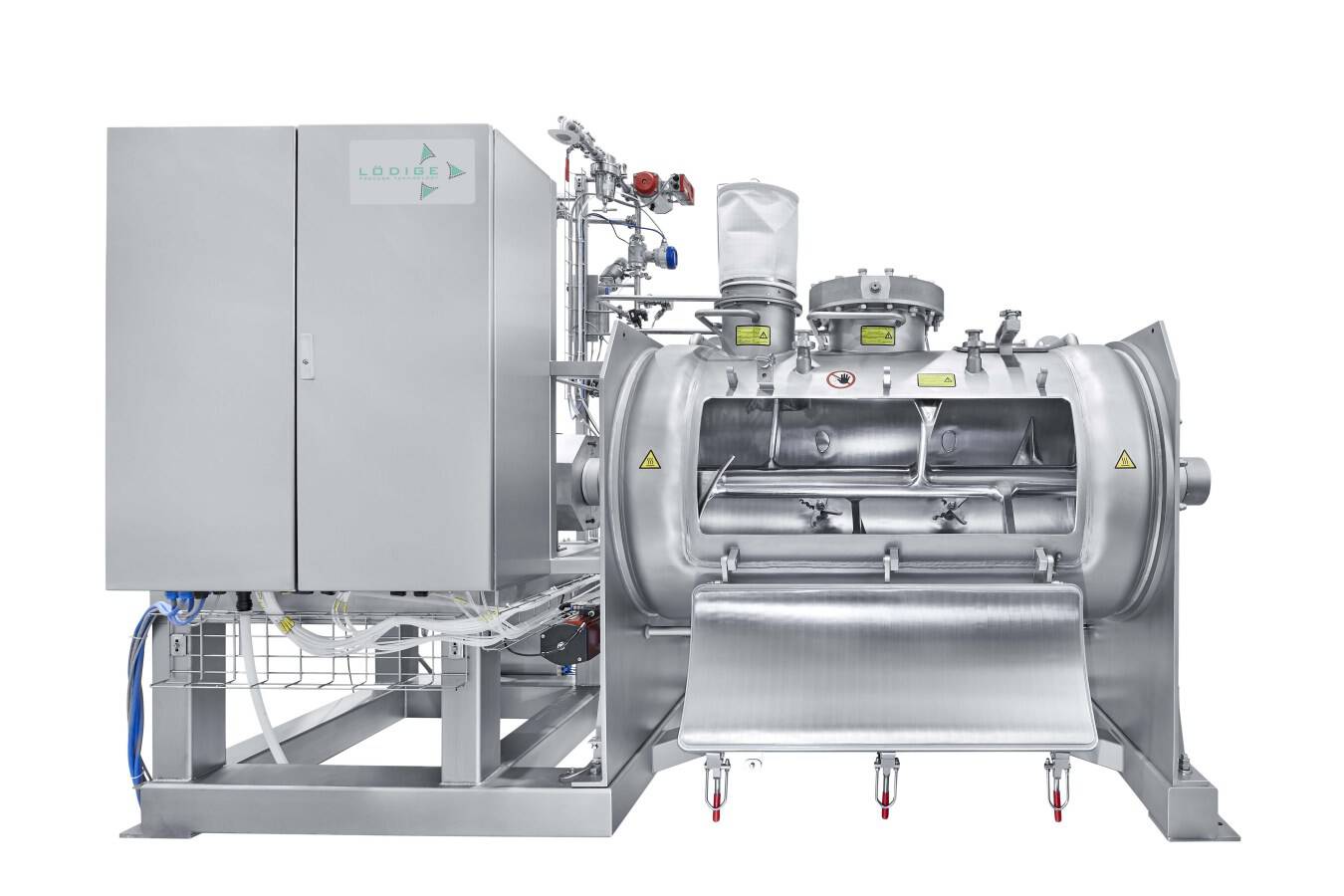

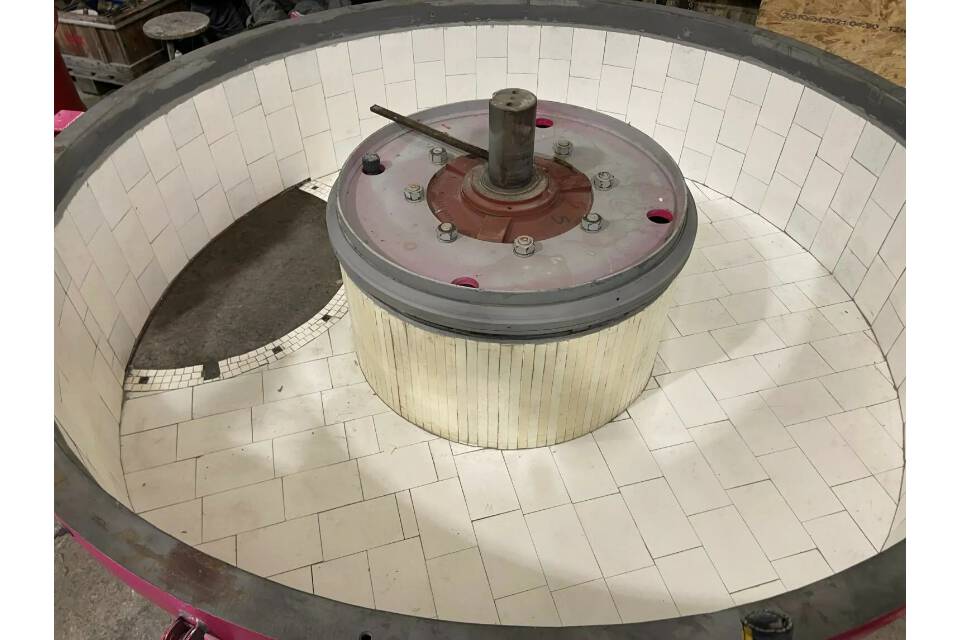

PerMix mixer functions to increase mixing efficiency and profitability Industrial mixers are essential for the processing of powders, pastes, and liquids in industries such as chemicals, plastics, paints, food, pharmaceuticals, and nutraceuticals. However, selecting the right mixer for an application can be difficult. There are different types of mixers such as fluidised zone, plough, paddle, ribbon, or sigma. Variations in quality between domestically sourced and overseas options can also be a concern.

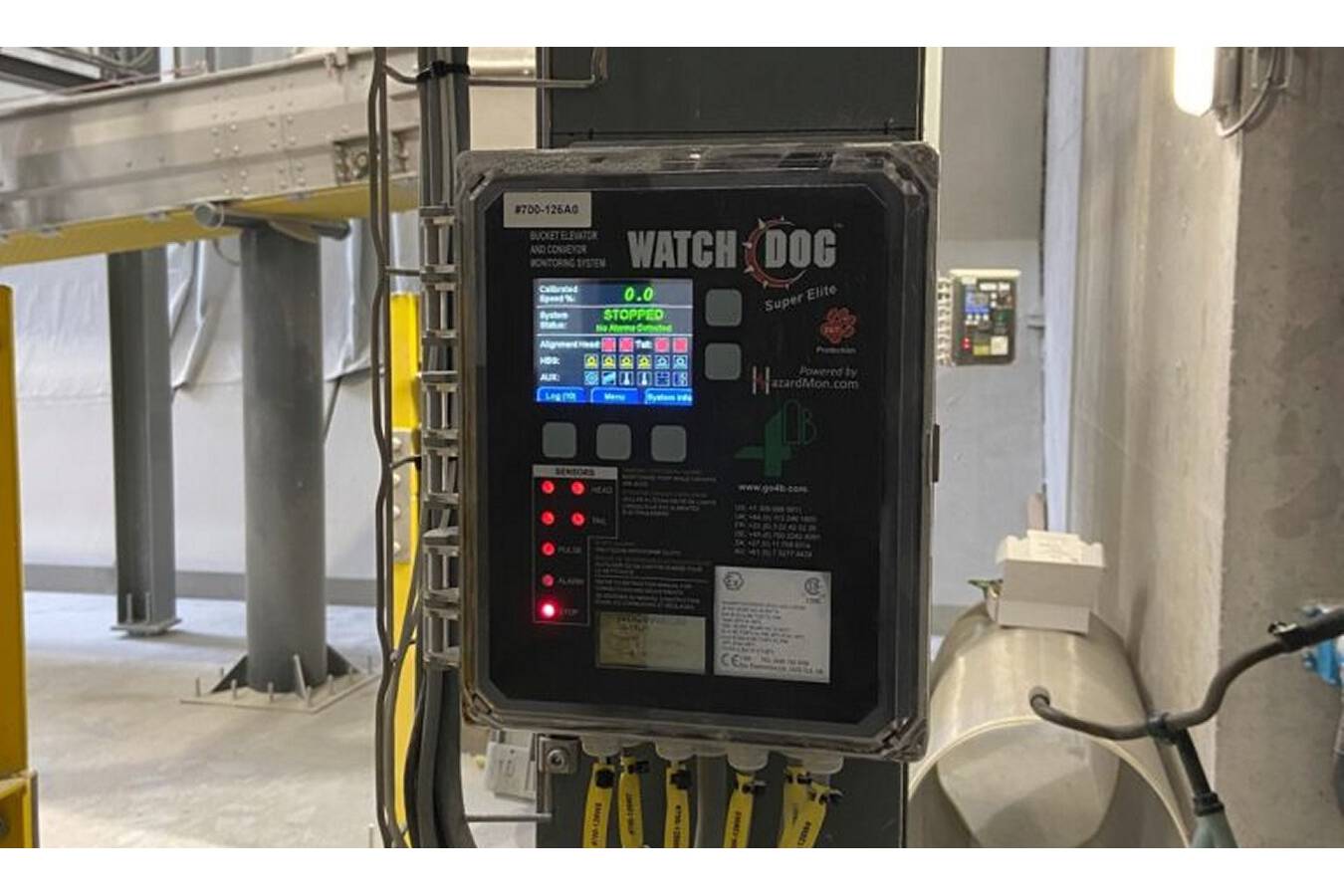

Regardless of the industry or type of mixer, quality and performance are crucial to attain the required product specifications while meeting inevitable changes in customer demand. In addition, with the current cost of labour and energy so high, it is vital to optimise efficiencies wherever possible for long- term profitability. To this end, industrial processors are increasingly seeking mixers with design features and capabilities that improve performance, provide more flexibility of mixing style, limit product loss, simplify cleaning