Compact 12,000 gauss stainless steel pipe magnet separator by Goudsmit

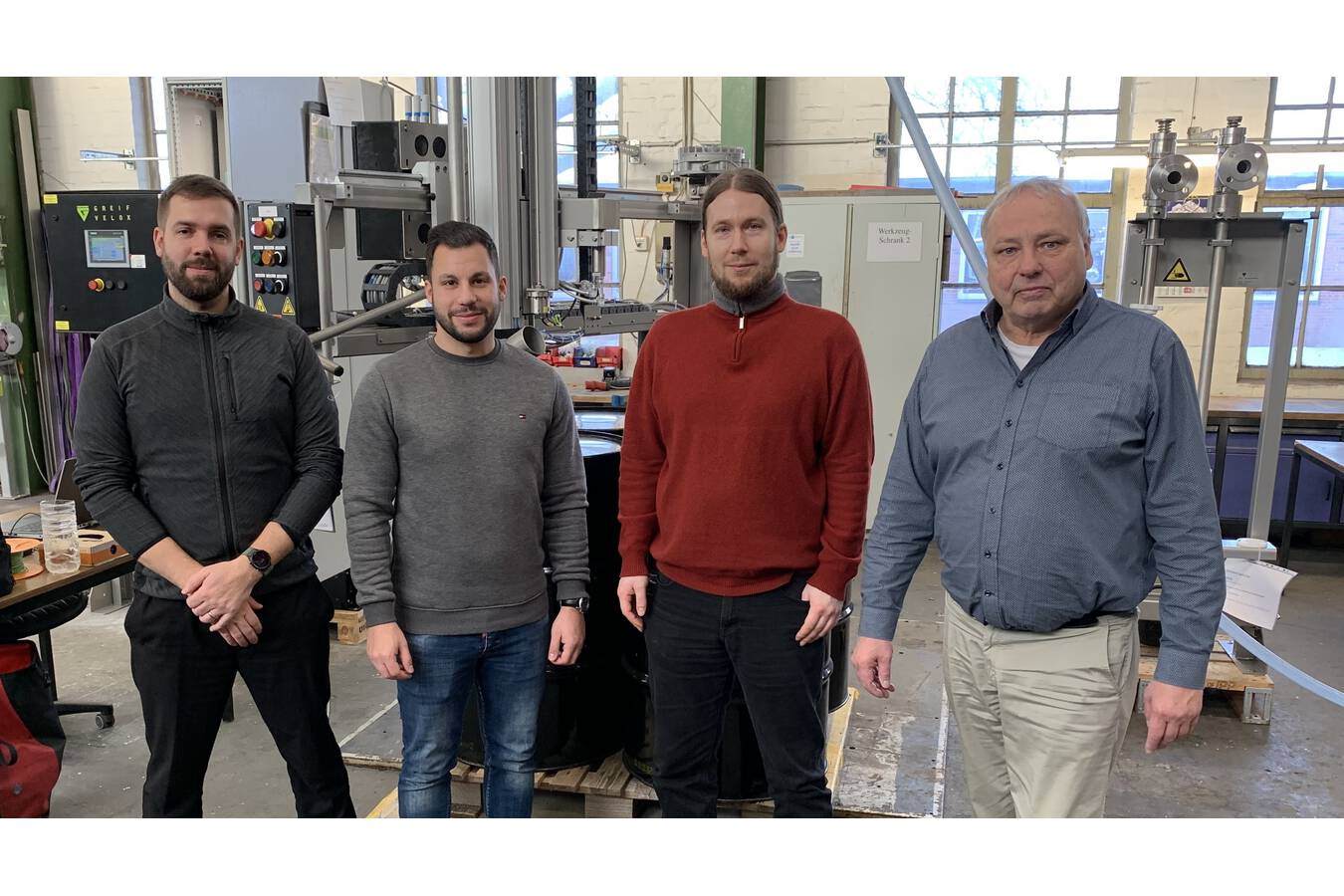

Goudsmit Magnetics (Waalre, Netherlands) has developed a new pipe magnet that requires half the installation height of its predecessor and is also twice as strong. Manufactured entirely from stainless steel, the magnetic separator contains a core of neodymium (NdFeB) magnets and creates a flux density of 12,000 gauss. The conical-shaped magnet core contains more pole plates, so even 30 µm particles stick to more engagement points.

This results in a higher degree of separation and also makes it possible to capture smaller metal particles in addition to coarse ones. Steel particles present in the product flow such as bolts, nuts, washers, screws, small metal balls, broken threads and clips can be effortlessly separated from grains, corn, flour, wheat flour and other incoming goods flows. The new magnet system is suitable not only for mounting in free-fall pipes, but also for pressure pipes. The stainless steel bullet magnet can be used in food but also other industries.

Low installation height & compact design

The 12,000 gauss pipe magnet was developed in response to specific market demands. The first requirement was to