The gentle processing of highly volatile oils by fluid bed technology

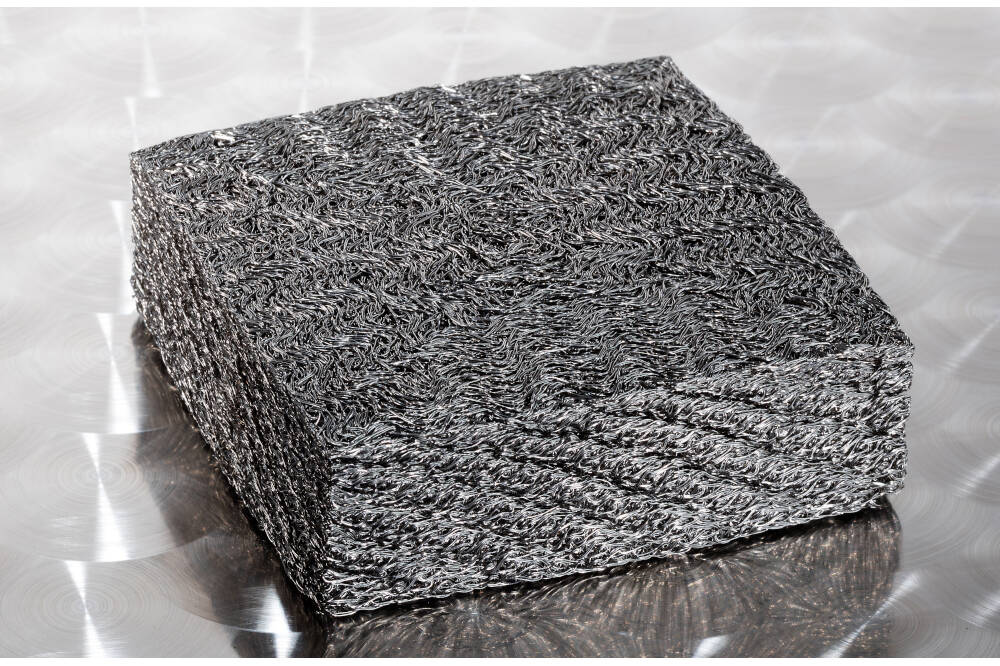

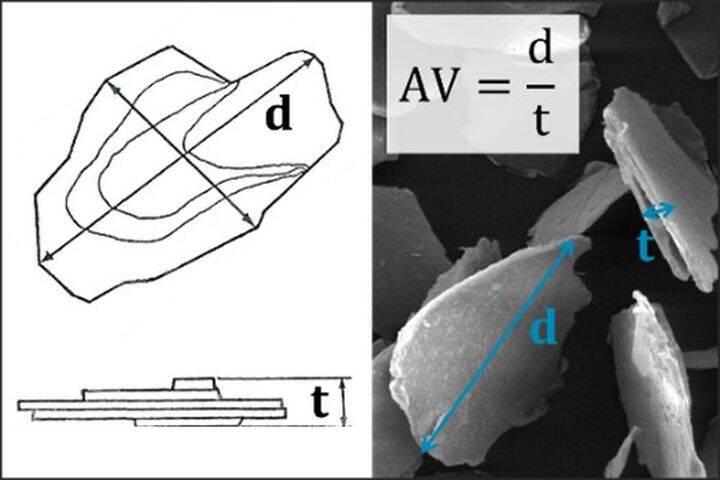

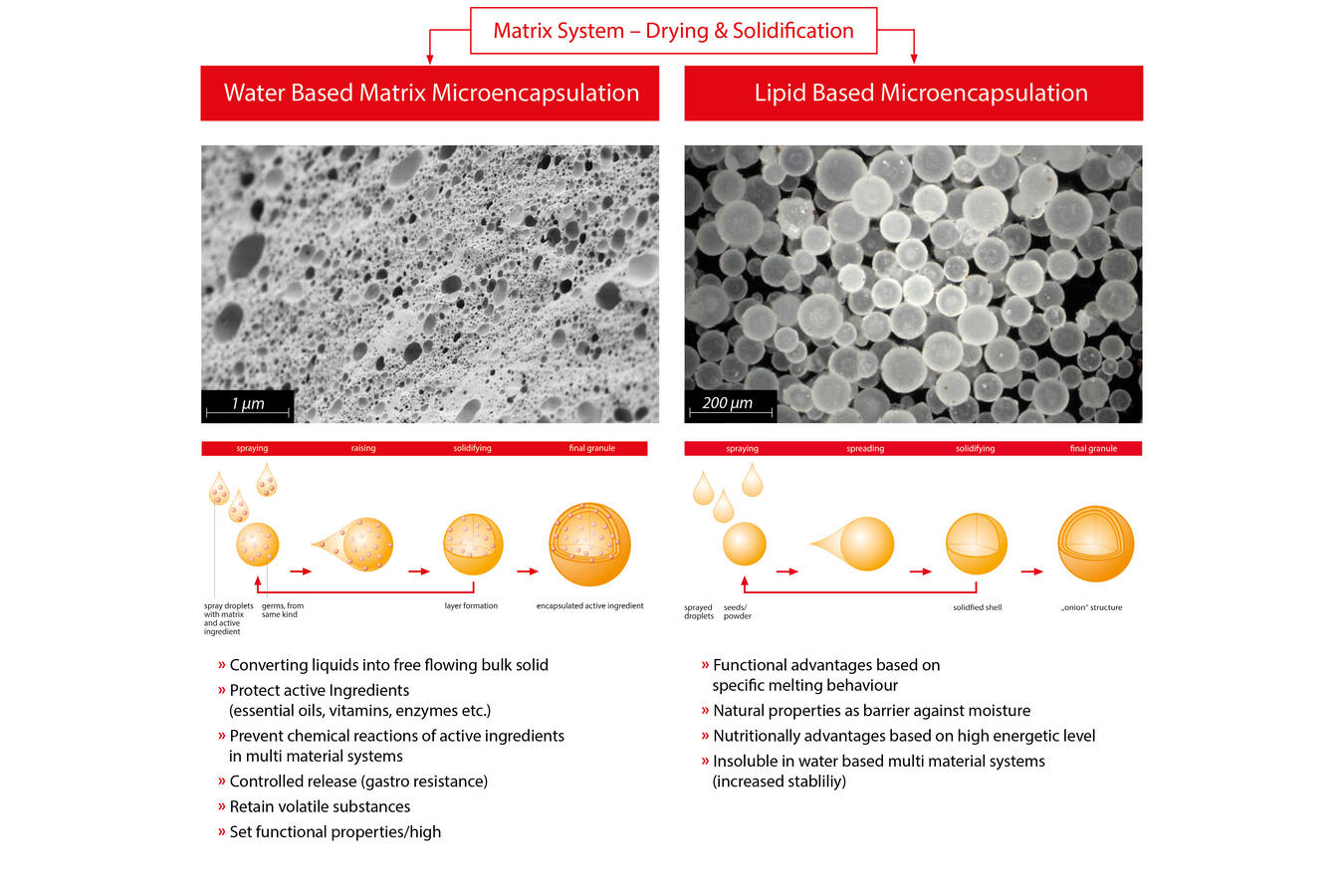

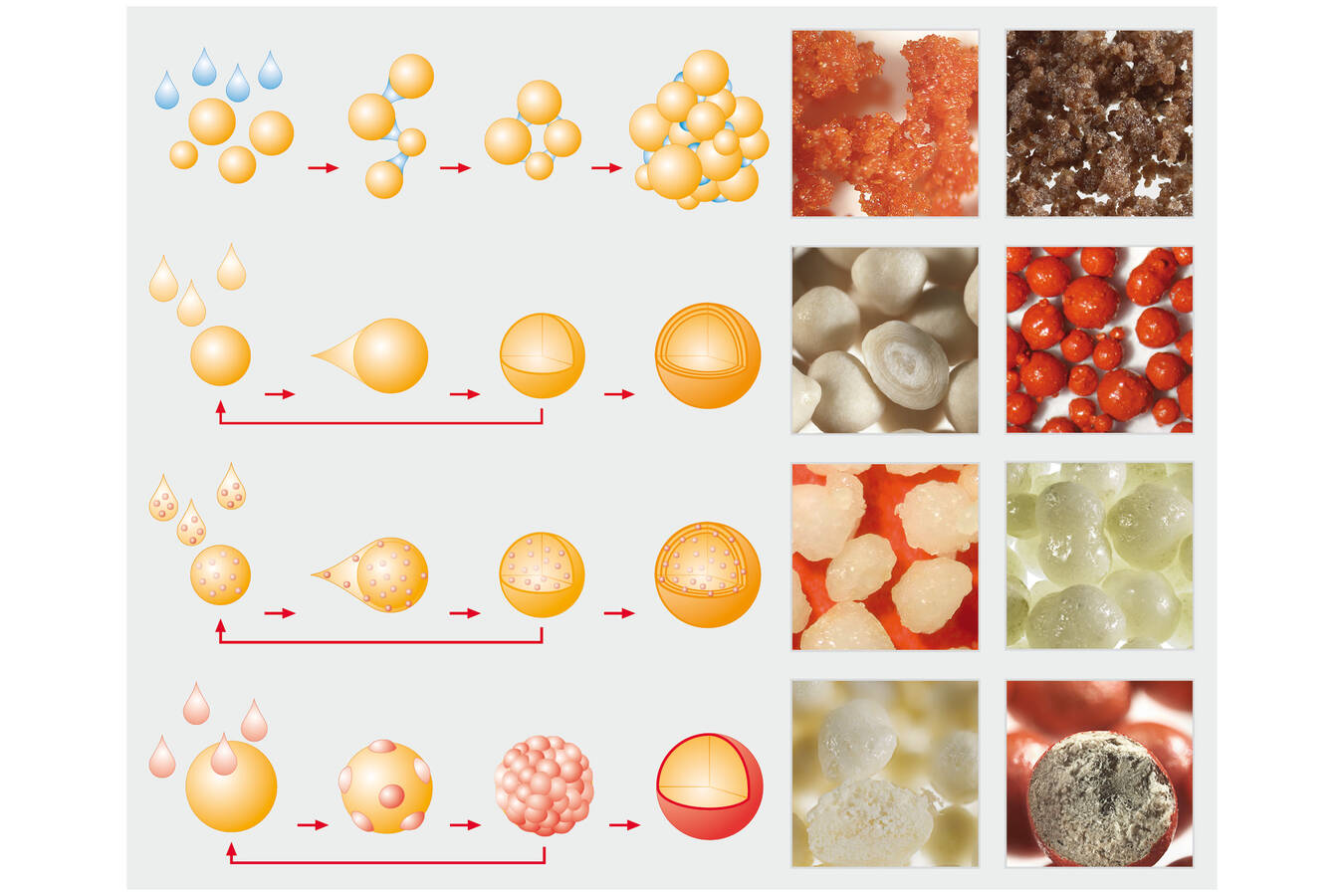

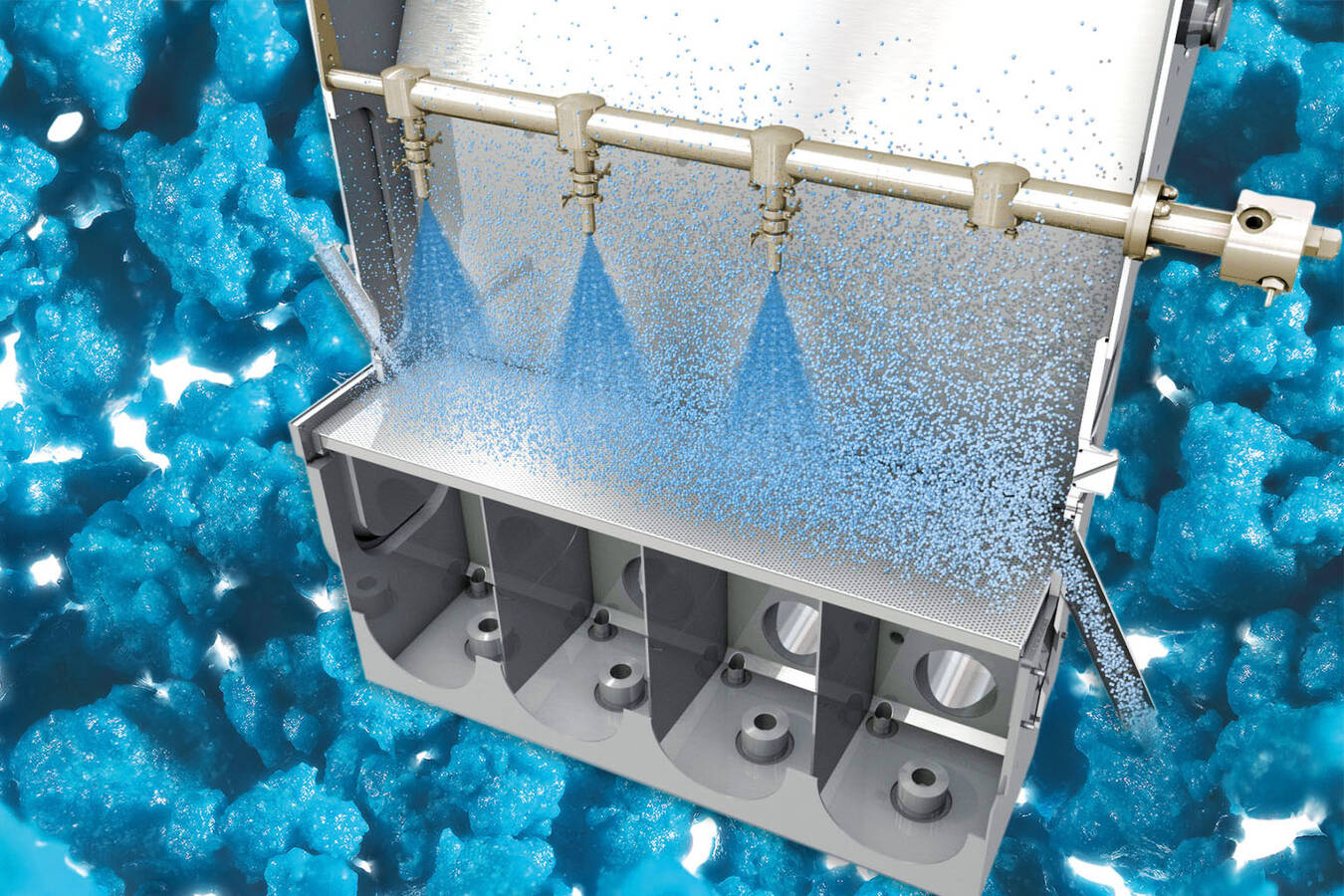

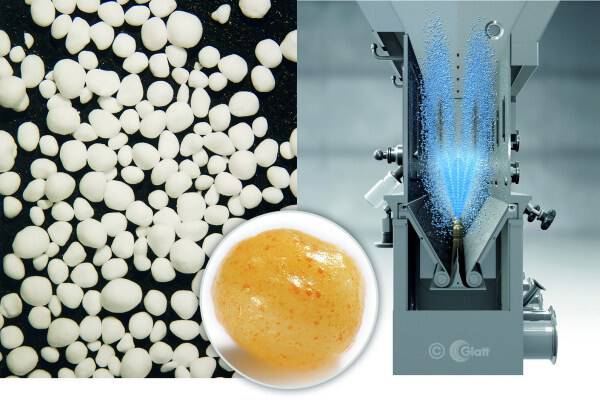

Sensitive raw materials, especially those that are volatile or of natural origin, require particularly gentle process conditions. Spray granulation, spray coating and (micro)encapsulation procedures have proven to be methods of choice, as they enable high yields, low temperatures and bespoke properties.

When it comes to cosmetics, product development often focuses on proven, multifunctional ingredients. This is in addition to the ongoing demand for natural ingredients, as consumers increasingly look for effective cosmetic products that neither harm their health nor the environment. Glatt Ingenieurtechnik, the German expert in particle design, process development and plant engineering, offers unique particle processing solutions based on fluidised bed and spouted bed technologies for essential oils, collagens, active substances, stabilizers, enzymes, fragrances, aromas, vitamins and controlled release products, all of which can be optimally produced, protected and refined.

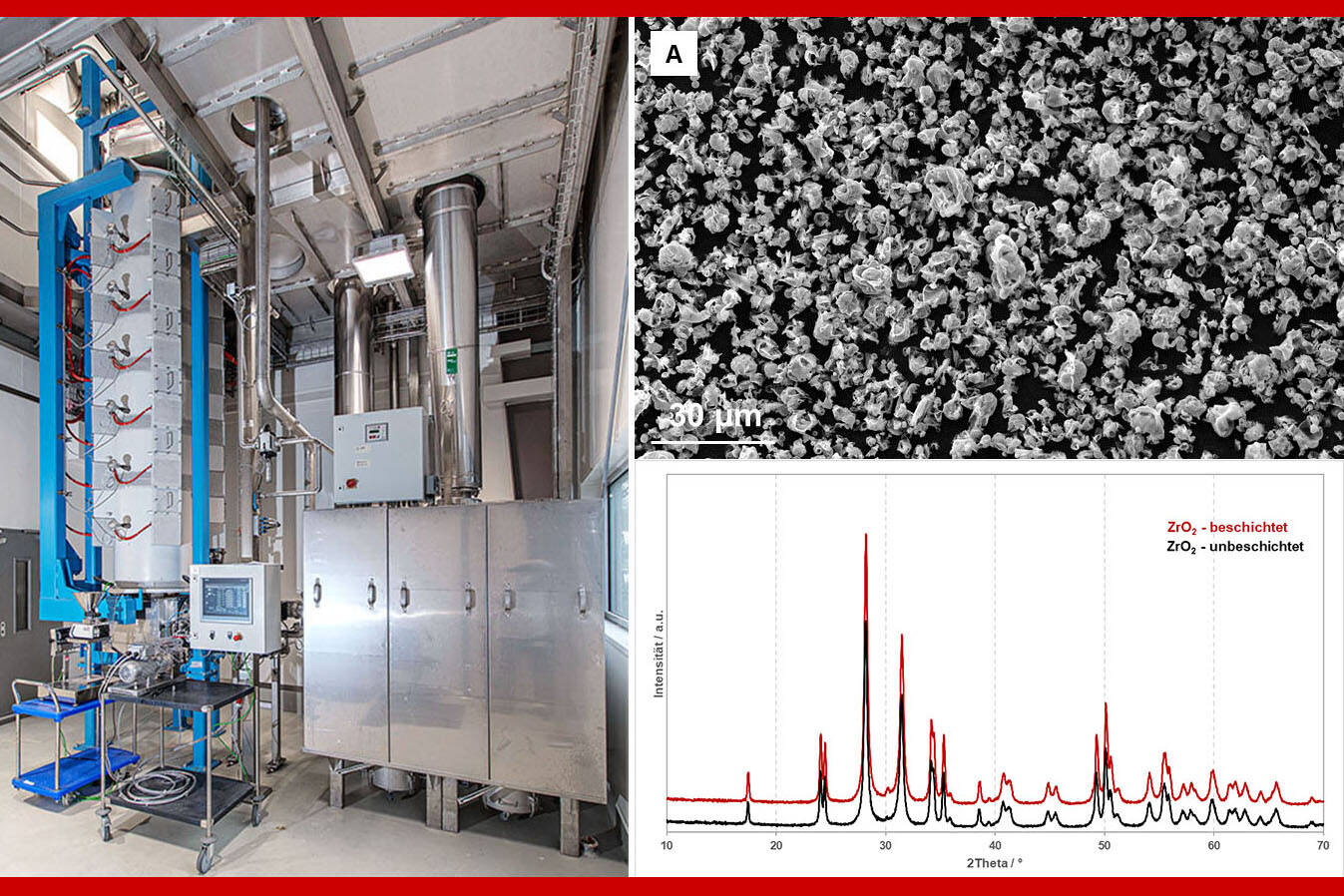

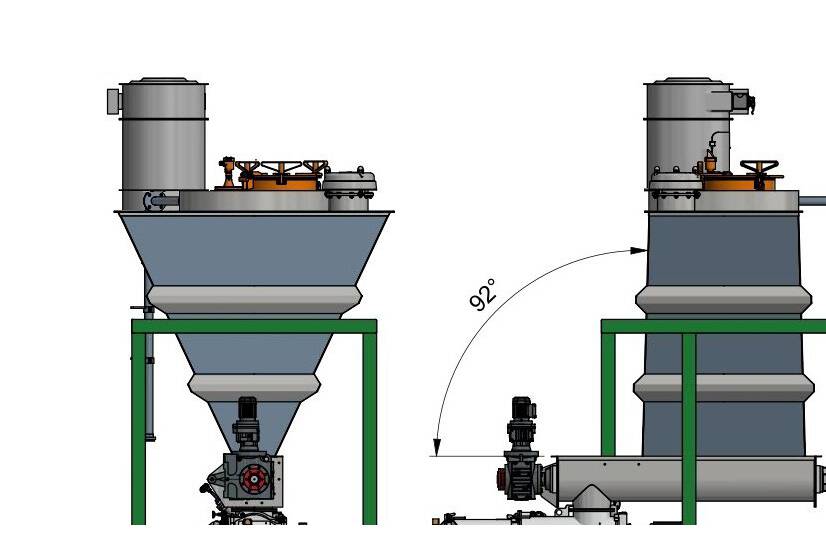

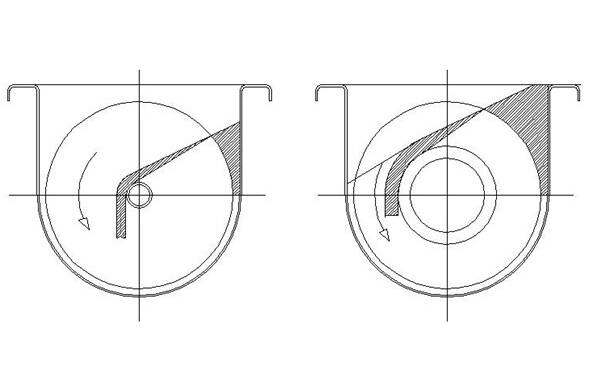

Efficient fluidised and spouted bed processes

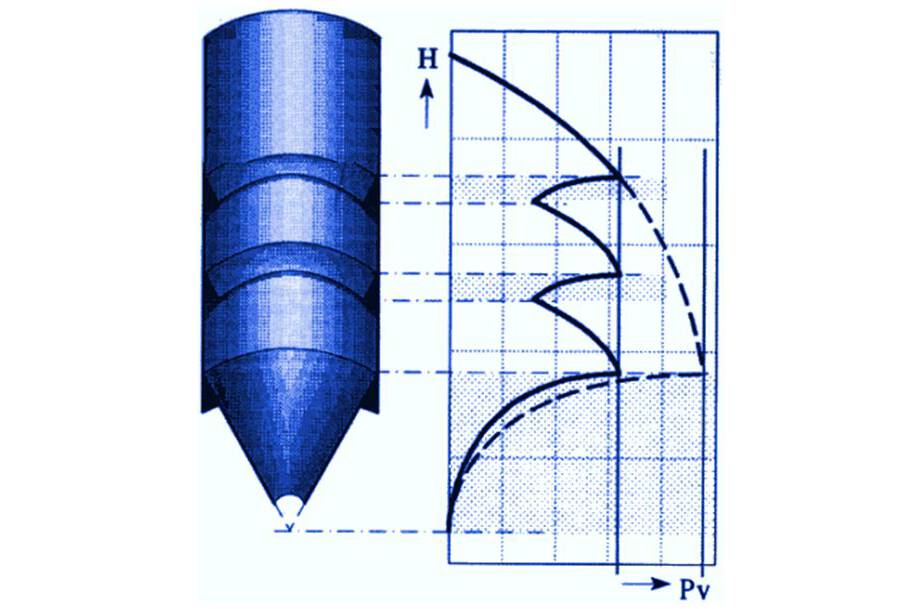

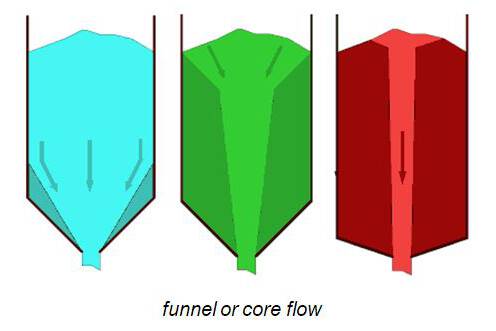

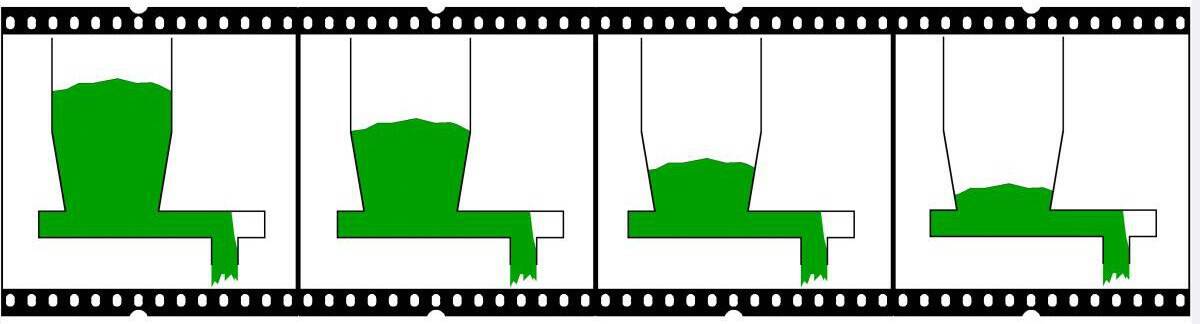

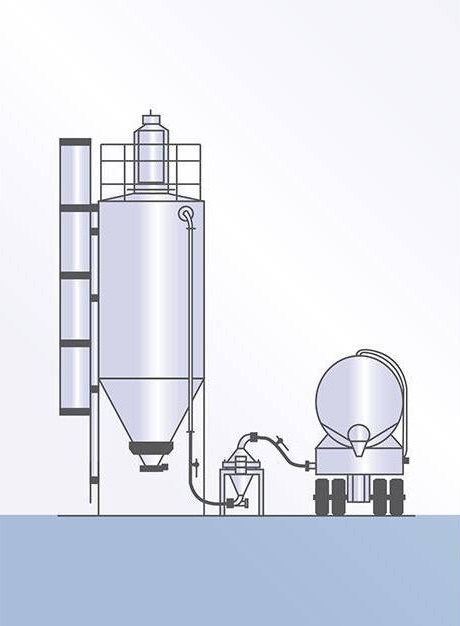

Unique flow, mechanical and thermodynamic properties make fluid bed technology