Brabender increases operating panel with Congrav OP12 Touch.

12 inch, interactive control panel for gravimetric feeding In 2005 Brabender Technologie KG, Duisburg, Germany, introduced with great success the Congrav OP5 Touch, a 5 inch touch screen control panel interactive machine operator interface for gravimetric feeding.

To meet the need in the market for a larger operation screen, a 12 inch design is available in the meantime.

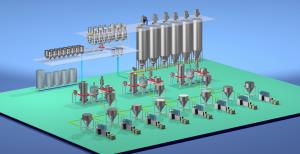

The Congrav OP12 Touch serves for central operation of up to 16 Brabender weigh-feeders (LIW-feeders, weigh-belt feeders, etc.), either with Congrav ISC-CM control modules (integrated with each feeder) and/or connected to the Congrav CB control board (mounted in central control cabinet). The ISC-CM modules and / or Congrav CB boards are interconnected by a field bus, which is easily connected to the operating panel Congrav OP12 Touch by just one single cable.

Operation of the Congrav OP12 Touch is made easy by language independent and self-explaining

touch-sensitive input fields on a large 12.1` colour display. Based on ® Windows®, the display allows