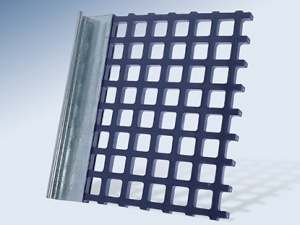

Great performance on a small footprint.

HAVER screening machines DMS and UMD. With more than 75 years of experience in the screening machine manufacture, mineral processing technology is not only a valuable part of the Haver & Boecker company history but also one of the technical cornerstones of the company. To this day, the name NIAGARA stands for quality, robustness, and performance. Three sites in Germany, Canada, and Brazil collaborated to form the Haver & Tyler Alliance for the sector of mineral processing technology. Haver & Tyler designs, produces, and provides support for premium stateof-the-art technologies in the field of screening, washing, and pelletising.

For screening small production volumes and small single batches and for applications on laboratory and pilot plant scale, Haver & Boecker Wire Weaving Division offers two sleek screening machines. Both machines are available in one- and two-deck design.

The HAVER DMS and the HAVER UMD are suitable for a large variety of bulk materials such as sand, gravel, ore, or coal, as