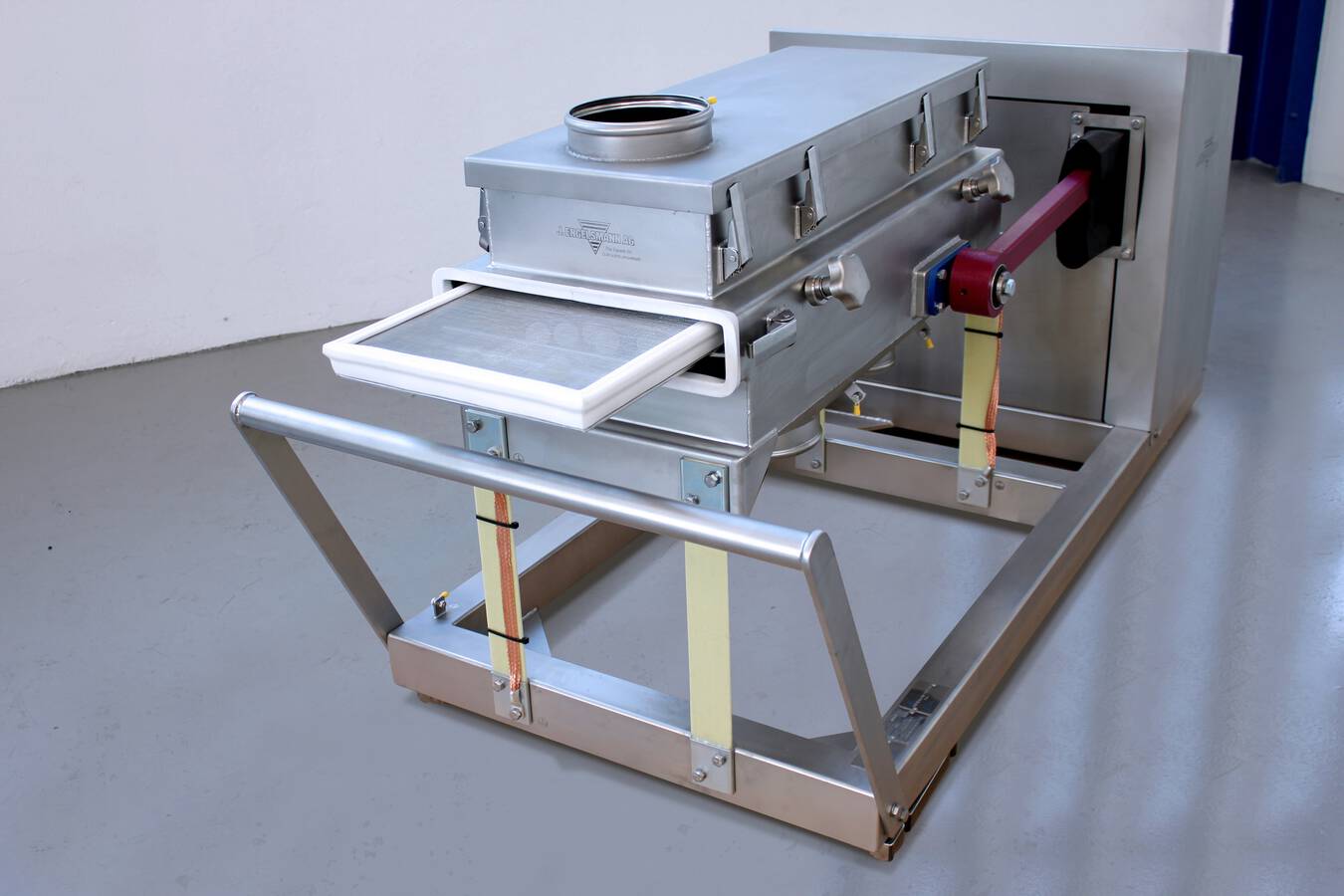

The Vibratory Ball Mill for grinding and sieving in one unit!

Fine comminution and sieving in one unit! The FRITSCH Vibratory Micro Mill PULVERISETTE 0 is the ideal laboratory mill for fine comminution of medium-hard, brittle, moist or temperature-sensitive samples – dry or in suspension – as well as for homogenising of emulsions and pastes.

For perfect, loss-free grinding results in shortest times!

Ideal for

- Chemical analysis: Electron microscopy

- Environmental research: Soil samples, comminution of botanical materials – also possible deep frozen

- Pharmaceuticals and medicine: Ophthalmological agents, gels, creams, extracts, drugs, pastes, dragées, tablets

- Biotechnology: Tissue samples, botanical matter

- Forensic analysis: Teeth, bones

- Materials technology: Pigments, precious materials, new materials

- RoHS: Mobile phone circuit boards, mobile phone cameras, mobile phone LCD glass panels, mobile phone keypads, electronic chips, LCD diffusion panels

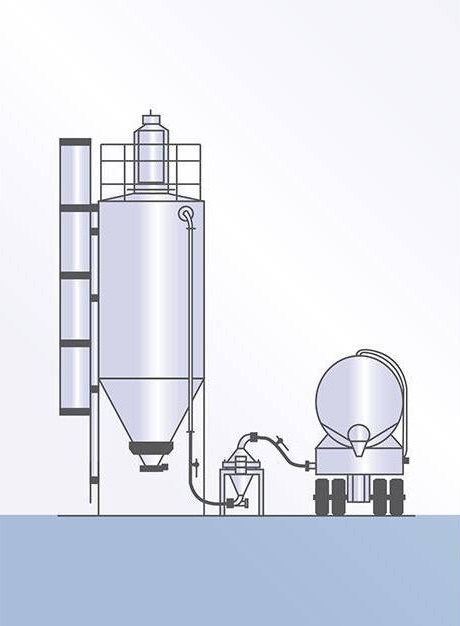

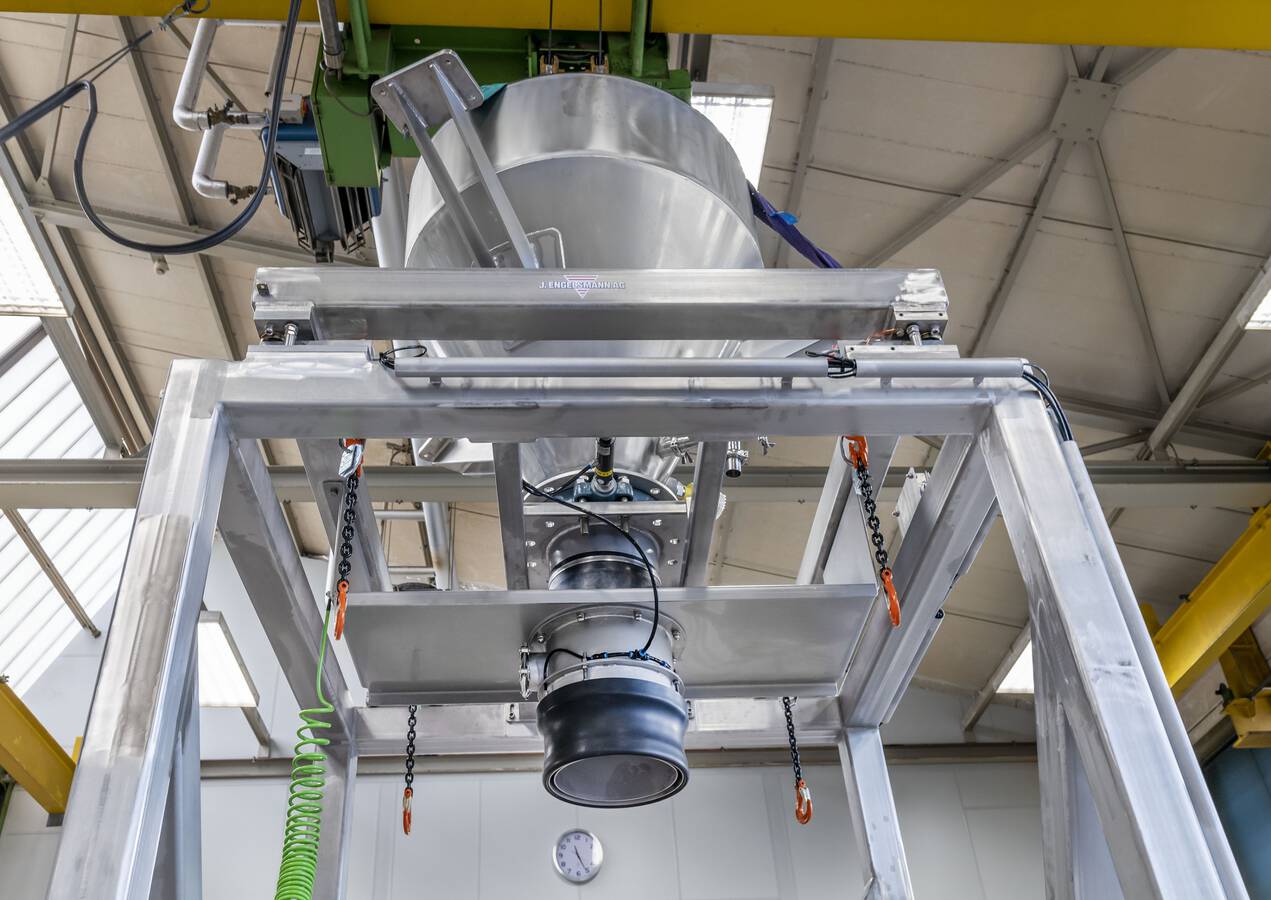

Cryogenic grinding

For fast embrittlement of soft, slightly oily, fatty or moist materials